Filter News

Area of Research

- (-) Advanced Manufacturing (4)

- Biological Systems (4)

- Biology and Environment (56)

- Biology and Soft Matter (3)

- Building Technologies (4)

- Chemical and Engineering Materials (2)

- Chemistry and Physics at Interfaces (5)

- Clean Energy (82)

- Climate and Environmental Systems (4)

- Computational Biology (1)

- Computational Chemistry (4)

- Computational Engineering (2)

- Computer Science (3)

- Earth Sciences (1)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (6)

- Energy Sciences (1)

- Fuel Cycle Science and Technology (2)

- Functional Materials for Energy (8)

- Fusion and Fission (19)

- Fusion Energy (3)

- Geographic Information Science and Technology (1)

- Isotope Development and Production (1)

- Isotopes (15)

- Materials (107)

- Materials Characterization (2)

- Materials for Computing (7)

- Materials Synthesis from Atoms to Systems (8)

- Materials Under Extremes (6)

- National Security (26)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (38)

- Nuclear Science and Technology (7)

- Nuclear Systems Technology (1)

- Quantum Condensed Matter (2)

- Renewable Energy (1)

- Sensors and Controls (1)

- Supercomputing (88)

- Transportation Systems (3)

News Type

Media Contacts

Researchers at the Department of Energy’s Oak Ridge National Laboratory have improved flaw detection to increase confidence in metal parts that are 3D-printed using laser powder bed fusion.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated an additive manufacturing method to control the structure and properties of metal components with precision unmatched by conventional manufacturing processes. Ryan D...

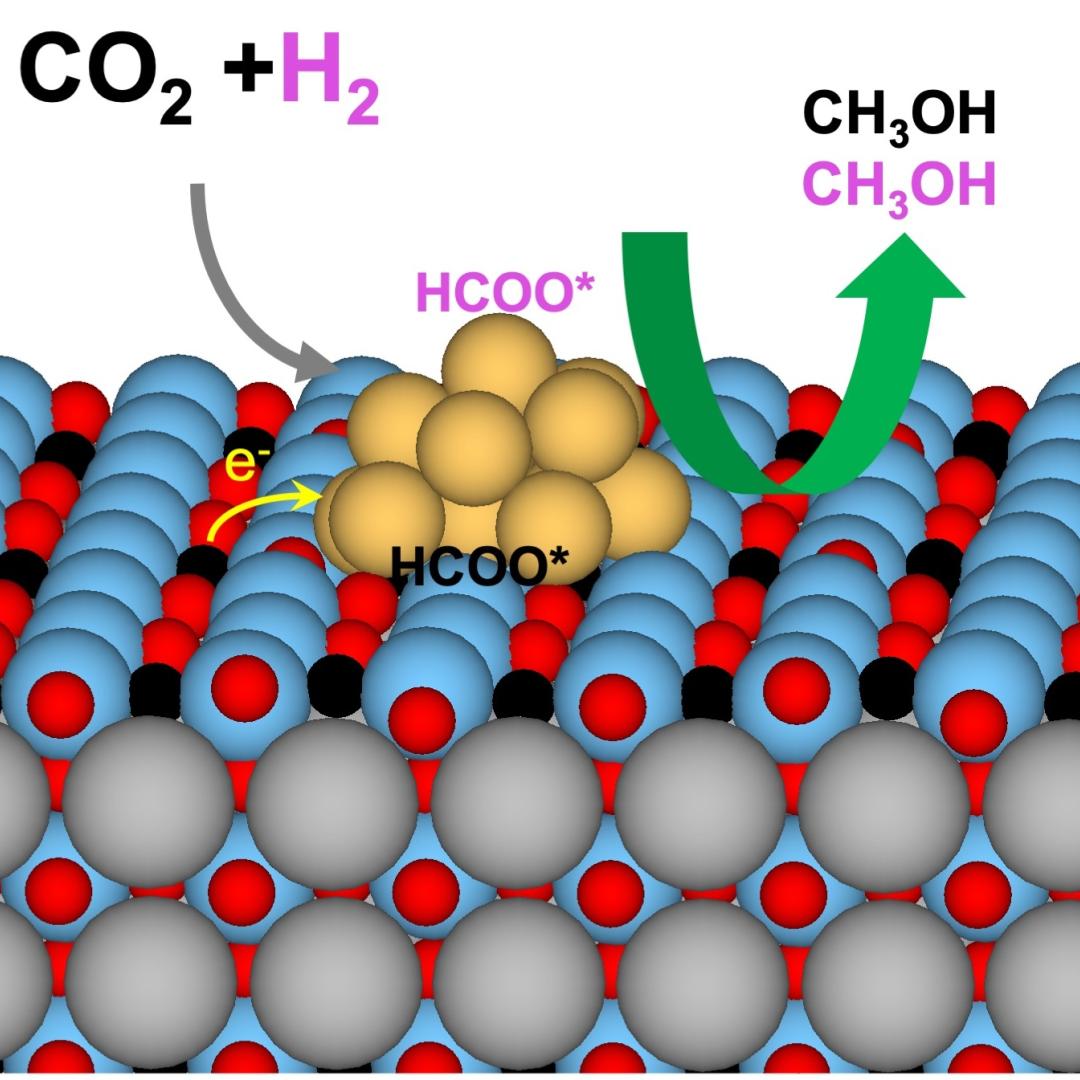

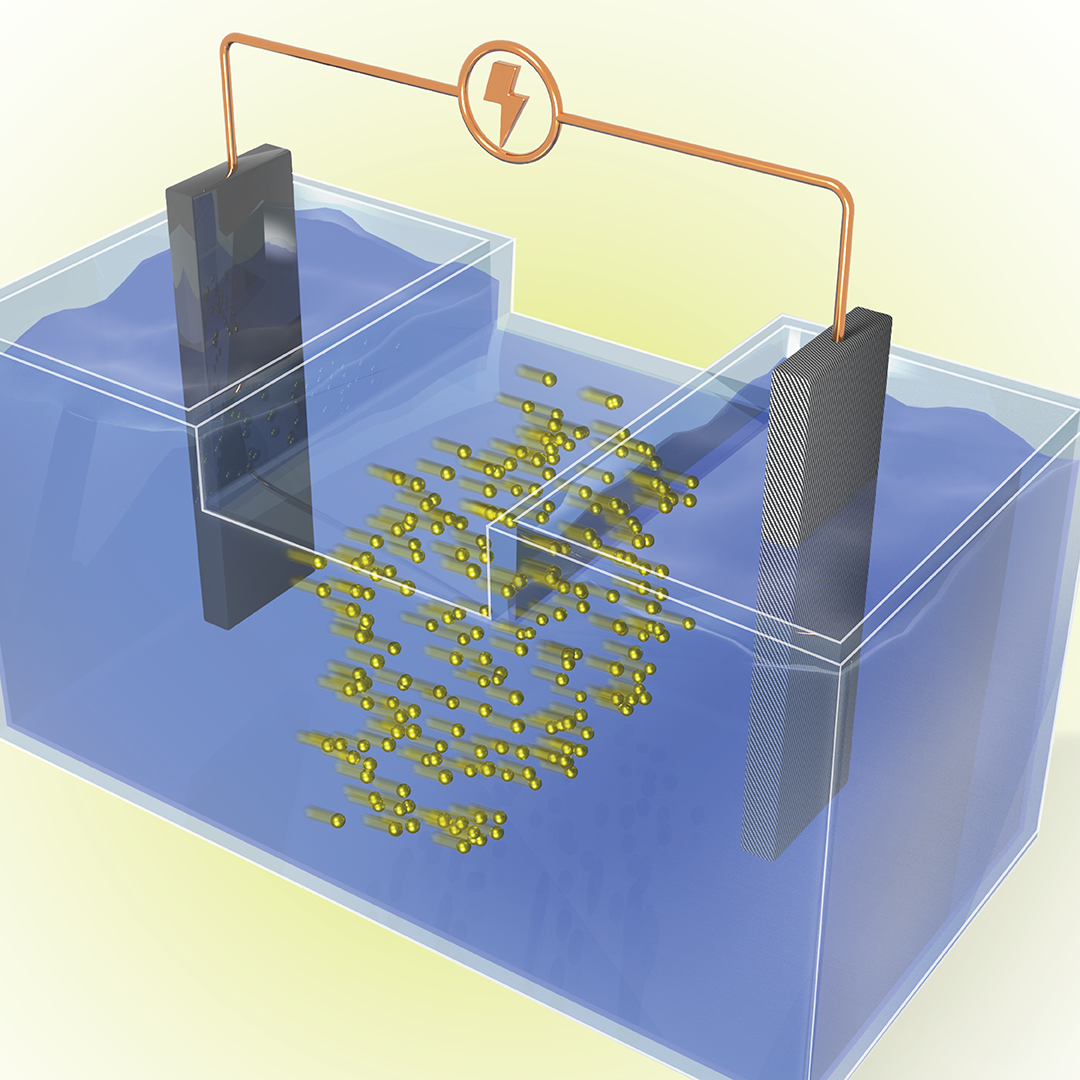

Complex oxides have long tantalized the materials science community for their promise in next-generation energy and information technologies. Complex oxide crystals combine oxygen atoms with assorted metals to produce unusual and very desirable properties.

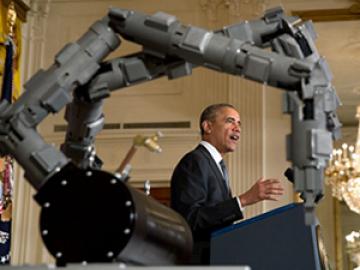

University of Tennessee (UT)-Oak Ridge National Laboratory Governor's Chair for Advanced Manufacturing Suresh Babu will lead the University of Tennessee's effort as part of a Detroit-based Lightweight and Modern Metals Manufacturing Innovation institute announced by President Obama on Feb. 25.