Filter News

Area of Research

- (-) Advanced Manufacturing (7)

- (-) Materials Synthesis from Atoms to Systems (5)

- Biological Systems (3)

- Biology and Environment (17)

- Biology and Soft Matter (1)

- Building Technologies (2)

- Chemical and Engineering Materials (2)

- Chemistry and Physics at Interfaces (6)

- Clean Energy (110)

- Climate and Environmental Systems (2)

- Computational Chemistry (1)

- Computer Science (2)

- Energy Frontier Research Centers (7)

- Energy Sciences (1)

- Functional Materials for Energy (6)

- Fusion and Fission (5)

- Fusion Energy (6)

- Geographic Information Science and Technology (2)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials (89)

- Materials for Computing (5)

- Materials Under Extremes (6)

- National Security (12)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (37)

- Nuclear Science and Technology (28)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum Condensed Matter (2)

- Quantum information Science (3)

- Reactor Technology (1)

- Supercomputing (58)

- Transportation Systems (2)

Media Contacts

The Society of Manufacturing Engineers, known as SME, has named William Peter, director of Oak Ridge National Laboratory’s Manufacturing Demonstration Facility in the Energy and Environmental Sciences Directorate, among its 2020 College of SME Fellows.

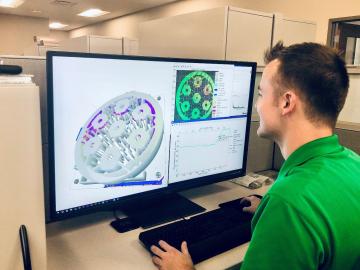

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

ORNL has licensed two additive manufacturing-related technologies that aim to streamline and ramp up production processes to Knoxville-based Magnum Venus Products, Inc., a global manufacturer of fluid movement and product solutions for industrial applications in composites and adhesives.

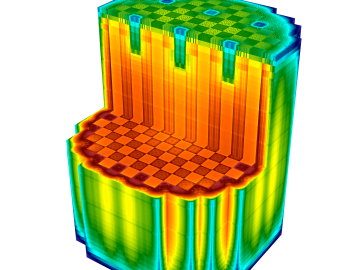

OAK RIDGE, Tenn., Feb. 19, 2020 — The U.S. Department of Energy’s Oak Ridge National Laboratory and the Tennessee Valley Authority have signed a memorandum of understanding to evaluate a new generation of flexible, cost-effective advanced nuclear reactors.

A research demonstration unveiled today at the Department of Energy’s Oak Ridge National Laboratory combines clean energy technologies into a 3D-printed building and vehicle to showcase a new approach to energy use, storage and consumption. The Additive Manufactur...

From the bluebird painting propped against her office wall and the deer she mentions seeing outside her office window, Linda Lewis might be mistaken for a wildlife biologist at first glance. But rather than trailing animal tracks, Lewis, a researcher at the Department of Energy’s Oak Ridge National Laboratory, is more interested in marks left behind by humans.

With more than 30 patents, James Klett is no stranger to success, but perhaps the Oak Ridge National Laboratory researcher’s most noteworthy achievement didn’t start out so hot – or so it seemed at the time.

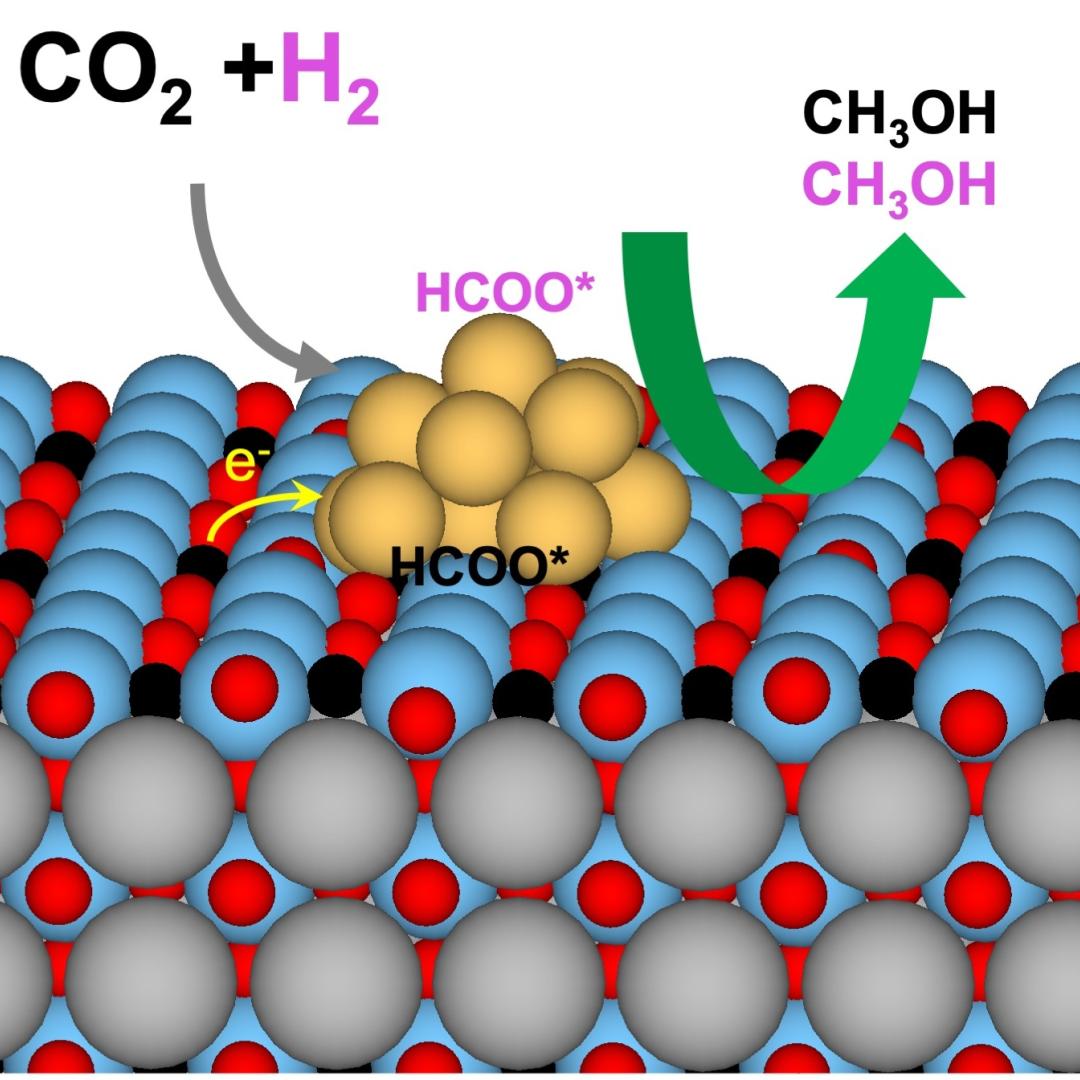

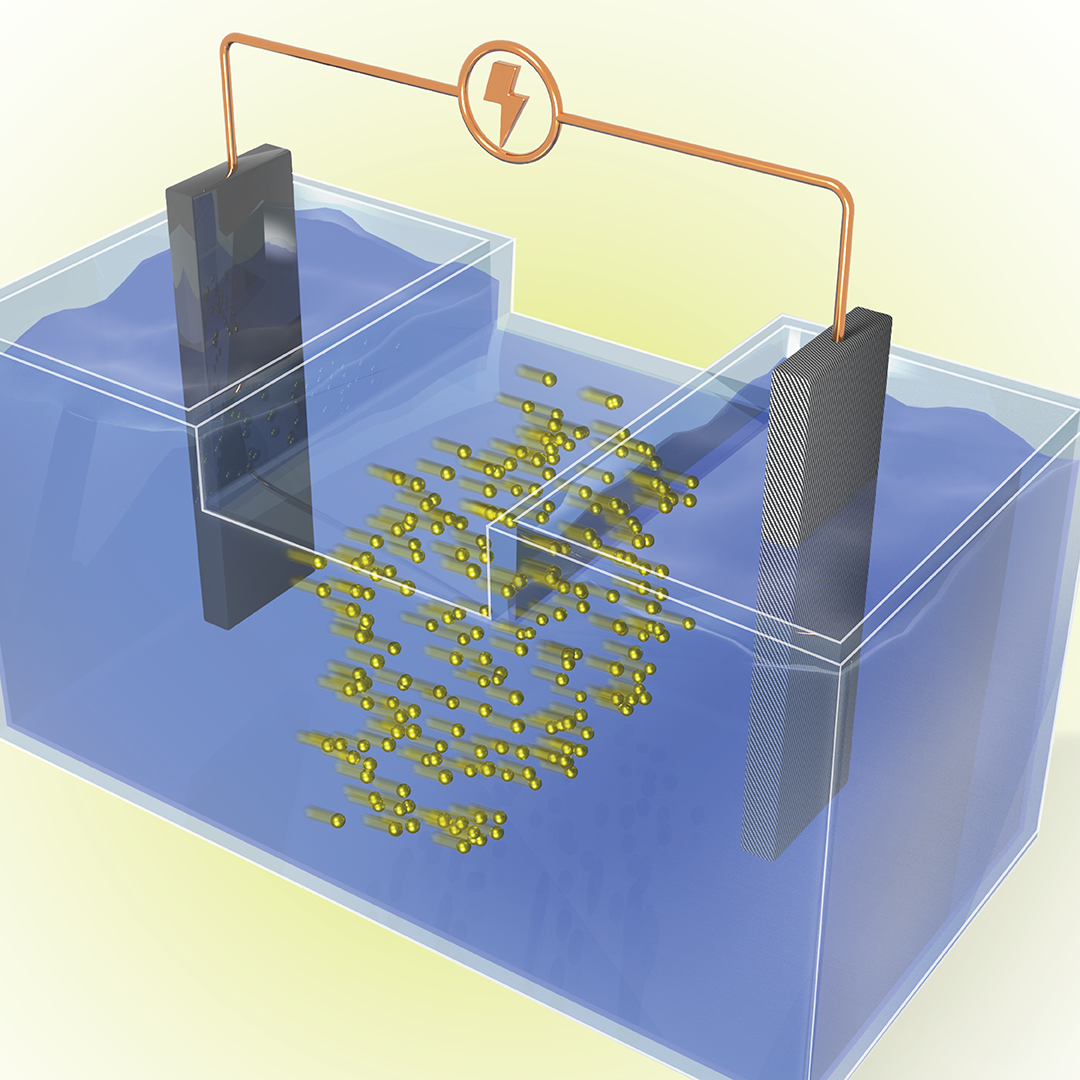

Graphene, a strong, lightweight carbon honeycombed structure that’s only one atom thick, holds great promise for energy research and development. Recently scientists with the Fluid Interface Reactions, Structures, and Transport (FIRST) Energy Frontier Research Center (EFRC), led by the US Department of Energy’s Oak Ridge National Laboratory, revealed graphene can serve as a proton-selective permeable membrane, providing a new basis for streamlined and more efficient energy technologies such as improved fuel cells.