Filter News

Area of Research

- (-) Clean Energy (104)

- Advanced Manufacturing (4)

- Biological Systems (4)

- Biology and Environment (56)

- Biology and Soft Matter (1)

- Building Technologies (3)

- Chemical and Engineering Materials (2)

- Chemistry and Physics at Interfaces (6)

- Computational Chemistry (1)

- Computational Engineering (1)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Frontier Research Centers (7)

- Energy Sciences (1)

- Fuel Cycle Science and Technology (1)

- Functional Materials for Energy (6)

- Fusion and Fission (19)

- Fusion Energy (4)

- Geographic Information Science and Technology (2)

- Isotope Development and Production (2)

- Isotopes (15)

- Materials (115)

- Materials Characterization (2)

- Materials Synthesis from Atoms to Systems (5)

- Materials Under Extremes (7)

- National Security (26)

- Neutron Data Analysis and Visualization (2)

- Neutron Science (42)

- Nuclear Science and Technology (8)

- Quantum Condensed Matter (2)

- Reactor Technology (1)

- Supercomputing (93)

- Transportation Systems (2)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (14)

- Bioenergy (2)

- Biology (1)

- Biomedical (1)

- Biotechnology (1)

- Buildings (12)

- Chemical Sciences (7)

- Clean Water (1)

- Climate Change (3)

- Composites (5)

- Coronavirus (1)

- Critical Materials (2)

- Cybersecurity (2)

- Decarbonization (14)

- Energy Storage (14)

- Environment (3)

- Fossil Energy (1)

- Grid (12)

- Hydropower (1)

- Machine Learning (1)

- Materials (8)

- Materials Science (2)

- Microelectronics (1)

- Microscopy (1)

- National Security (2)

- Net Zero (1)

- Neutron Science (2)

- Nuclear Energy (1)

- Partnerships (7)

- Polymers (1)

- Renewable Energy (1)

- Security (1)

- Simulation (2)

- Sustainable Energy (5)

- Transportation (12)

Media Contacts

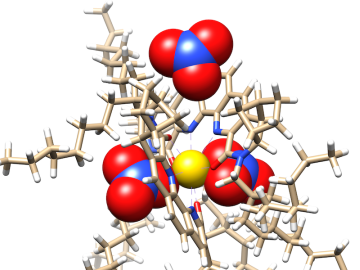

Researchers at ORNL zoomed in on molecules designed to recover critical materials via liquid-liquid extraction — a method used by industry to separate chemically similar elements.

The Department of Energy’s Center for Bioenergy Innovation, led by Oak Ridge National Laboratory, recently added three new members to its board of directors: Deborah Crawford of the University of Tennessee, Knoxville; Susan Hubbard of ORNL; and Maureen McCann of the National Renewable Energy Laboratory.

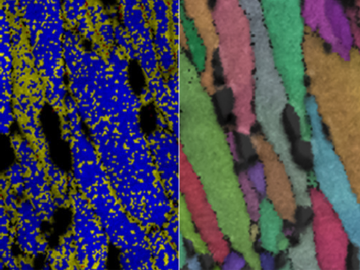

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

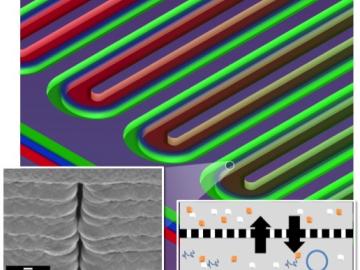

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received six R&D 100 Awards, increasing the lab’s total to 193 since the award’s inception in 1963. The competition, sponsored by R&D Magazine, recognizes advances in the nation’s ...

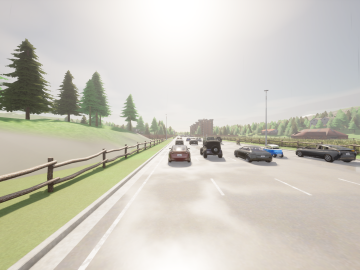

The Department of Energy’s Oak Ridge National Laboratory, FCA US LLC, and the foundry giant, Nemak of Mexico, are combining their strengths to create lightweight powertrain materials that will help the auto industry speed past the technological

A new study from the Department of Energy’s Oak Ridge National Laboratory explains the mechanism behind a technology that converts bio-based ethanol into hydrocarbon blend-stocks for use as fossil fuel alternatives. Scientists have experimented for decades with a cl...