Filter News

Area of Research

- (-) Materials (118)

- Advanced Manufacturing (2)

- Biological Systems (2)

- Biology and Environment (56)

- Building Technologies (1)

- Clean Energy (112)

- Climate and Environmental Systems (2)

- Computational Engineering (1)

- Computer Science (2)

- Electricity and Smart Grid (1)

- Energy Sciences (1)

- Fossil Energy (1)

- Fuel Cycle Science and Technology (1)

- Fusion and Fission (19)

- Fusion Energy (3)

- Isotope Development and Production (1)

- Isotopes (15)

- Materials Characterization (2)

- Materials Under Extremes (1)

- National Security (26)

- Neutron Science (47)

- Nuclear Science and Technology (9)

- Renewable Energy (2)

- Supercomputing (95)

- Transportation Systems (1)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (5)

- Advanced Reactors (1)

- Bioenergy (1)

- Biomedical (1)

- Buildings (3)

- Chemical Sciences (16)

- Climate Change (3)

- Composites (2)

- Computer Science (1)

- Coronavirus (1)

- Critical Materials (5)

- Decarbonization (4)

- Energy Storage (5)

- Environment (3)

- Fusion (2)

- Grid (2)

- Irradiation (1)

- Isotopes (3)

- Materials (40)

- Materials Science (7)

- Microscopy (3)

- Molten Salt (1)

- Nanotechnology (3)

- Net Zero (1)

- Neutron Science (8)

- Nuclear Energy (4)

- Partnerships (6)

- Physics (9)

- Polymers (4)

- Quantum Computing (2)

- Quantum Science (1)

- Renewable Energy (1)

- Sustainable Energy (1)

- Transportation (2)

Media Contacts

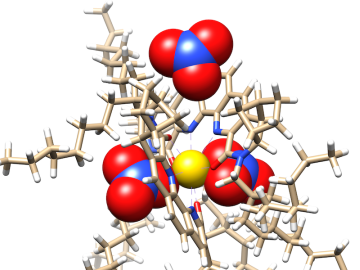

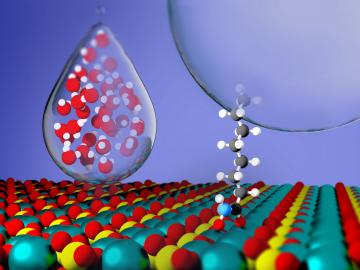

Researchers at ORNL zoomed in on molecules designed to recover critical materials via liquid-liquid extraction — a method used by industry to separate chemically similar elements.

Anne Campbell, an R&D associate in ORNL’s Materials Science and Technology Division since 2016, has been selected as an associate editor of the Journal of Nuclear Materials.

Eva Zarkadoula, an R&D staff member at ORNL’s Center for Nanophase Materials Sciences, has been appointed to the early career editorial board of Nuclear Materials and Energy.

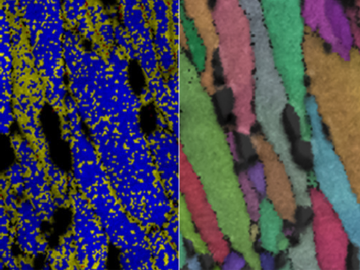

Critical Materials Institute researchers at Oak Ridge National Laboratory and Arizona State University studied the mineral monazite, an important source of rare-earth elements, to enhance methods of recovering critical materials for energy, defense and manufacturing applications.

Merlin Theodore is one of eight new board members announced by President Biden; she will join the 25-member board for a six-year term.

ORNL researchers have identified a mechanism in a 3D-printed alloy – termed “load shuffling” — that could enable the design of better-performing lightweight materials for vehicles.

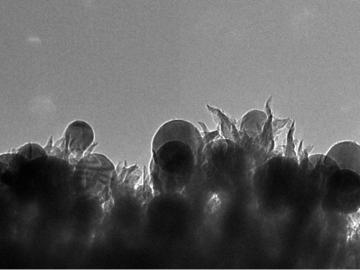

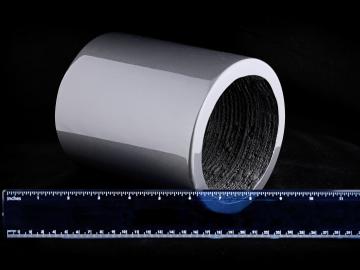

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated that permanent magnets produced by additive manufacturing can outperform bonded magnets made using traditional techniques while conserving critical materials. Scientists fabric...