Filter News

Area of Research

News Type

Date

News Topics

Media Contacts

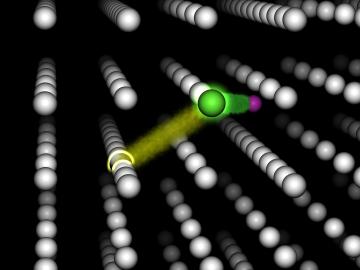

Researchers at Oak Ridge National Laboratory are taking a closer look at previously uncharacterized, microscopic soot particles collected during lab experiments on light-duty, multi-cylinder advanced combustion engines. The ORNL-led team is widely known for advancing a combustion te...

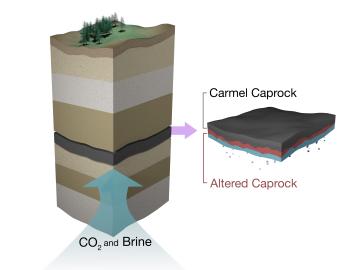

An Oak Ridge National Laboratory study is providing an unprecedented watershed-scale understanding of mercury in soils and sediments. Researchers focused on evaluating mercury and soil properties along the banks of a mercury-contaminated stream in Oak Ridge, Tenn., sampling 145 loca...

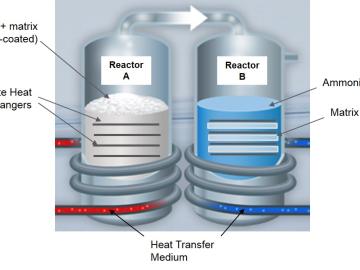

Salt and ammonia are key ingredients of a high-efficiency natural gas-fired heat pump system being developed by researchers at Oak Ridge National Laboratory, Rheem and ClimateWell. Potentially, the SaltX system could provide 43 percent greater efficiency than today’s best furn...

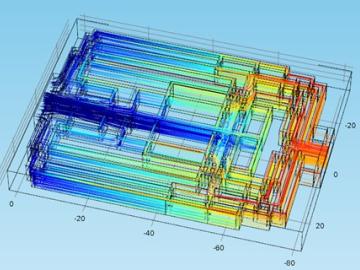

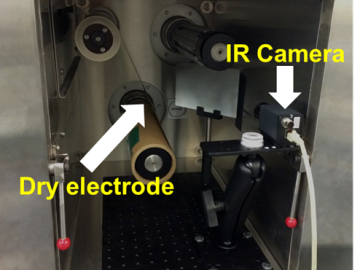

Production run spot checks of materials for lithium-ion batteries and fuel cells could be a thing of the past because of a process developed at Oak Ridge National Laboratory. The infrared/thermal nondestructive evaluation technique invented by a team led by David Wood examines key parameters such as porosity and thickness of the coating in real time without destroying product.