Filter News

Area of Research

News Type

Media Contacts

Six small companies will tap the expertise of the Department of Energy’s Oak Ridge National Laboratory to move their manufacturing, fuel cell, geothermal and vehicle technologies closer to the marketplace. The businesses are among 43 selected to participate in the ...

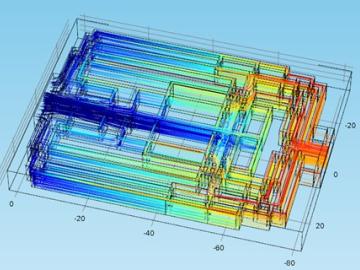

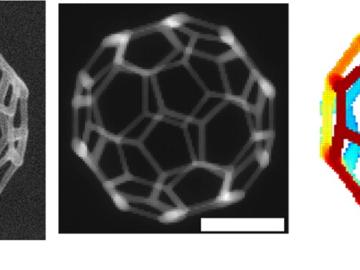

The US Department of Energy announced today that it will invest $16 million over the next four years to accelerate the design of new materials through use of supercomputers.

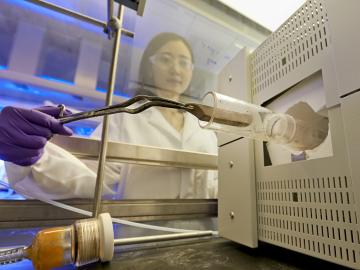

A process developed at Oak Ridge National Laboratory for large-scale recovery of rare earth magnets from used computer hard drives will undergo industrial testing under a new agreement between Oddello Industries LLC and ORNL, as part of the Department of Energy’s Crit...

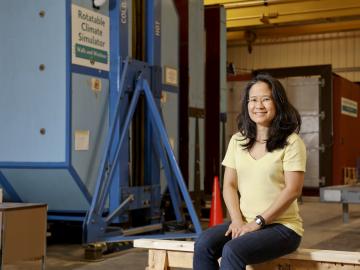

When Diana Hun left her home in Panama City, Panama, to attend school at the University of Texas in Austin, she knew she wanted to be an engineer. Exactly which branch of engineering to pursue was not quite as straight-forward. Hun studied both mechanical and electrical engin...

Sitting in the driver’s seat comes naturally to Ron Graves, the recently retired head of Oak Ridge National Laboratory’s sustainable transportation program. Graves has logged more than 100 days on national racetracks like Daytona, Road Atlanta, and Pocono where he routinely reache...

The 2016 Billion Ton Report, jointly released by the U.S. Department of Energy and Oak Ridge National Laboratory, concludes that the United States has the potential to sustainably produce at least 1 billion dry tons of nonfood biomass resources annually by 2040.

A scientist that sings opera and performs in musical theater? Sure. If you're a Renaissance Man like Simon Pallin. Pallin is a researcher in Oak Ridge National Laboratory’s Buildings Technologies Research & Integration Center. But his early interests and activities reveal a versatile person that could have chosen a number of occupations.