Filter News

Area of Research

Media Contacts

The recently discovered element 117 has been officially named "tennessine" in recognition of Tennessee’s contributions to its discovery, including the efforts of the Department of Energy's Oak Ridge National Laboratory and its Tennessee collaborators at Vanderbilt University and the University of Tennessee.

Scientists have developed a process for mixing unmodified lignin with general-purpose rubber and other components that yields high-performance renewable thermoplastics containing up to 41 percent of lignin content. The Oak Ridge National Laboratory-led research team tested two combinations of materials using different lignin varieties resulting in samples that were either “stretchy” or demonstrated tensile strength comparable to glassy plastic such as acrylonitrile butadiene styrene, or ABS.

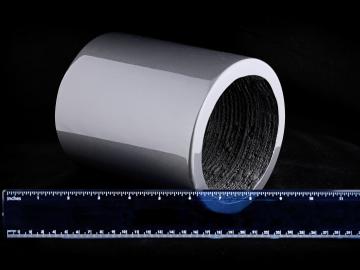

Researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated that permanent magnets produced by additive manufacturing can outperform bonded magnets made using traditional techniques while conserving critical materials. Scientists fabric...

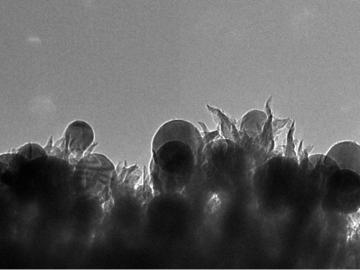

In a new twist to waste-to-fuel technology, scientists at the Department of Energy’s Oak Ridge National Laboratory have developed an electrochemical process that uses tiny spikes of carbon and copper to turn carbon dioxide, a greenhouse gas, into ethanol. Their findin...

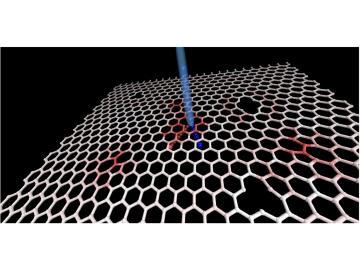

Researchers at Penn State, the Department of Energy’s Oak Ridge National Laboratory and Lockheed Martin Space Systems Company have developed methods to control defects in two-dimensional materials, such as graphene, that may lead to improved membranes for water desalination, energy...

Samsung Electronics has exclusively licensed optically clear superhydrophobic film technology from the Department of Energy’s Oak Ridge National Laboratory to improve the performance of glass displays on smartphones, tablets and other electronic devices.

O...

The lighter wand for your gas BBQ, a submarine’s sonar device and the ultrasound machine at your doctor’s office all rely on piezoelectric materials, which turn mechanical stress into electrical energy, and vice versa. In 1997, researchers developed piezoelectric...

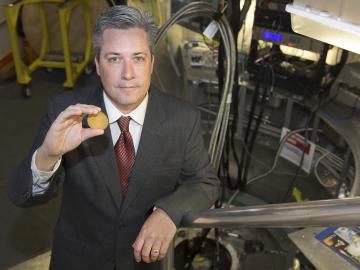

Scientists at the Department of Energy’s Oak Ridge National Laboratory are the first to harness a scanning transmission electron microscope (STEM) to directly write tiny patterns in metallic “ink,” forming features in liquid that are finer than half the width of a hum...

The US Department of Energy announced today that it will invest $16 million over the next four years to accelerate the design of new materials through use of supercomputers.

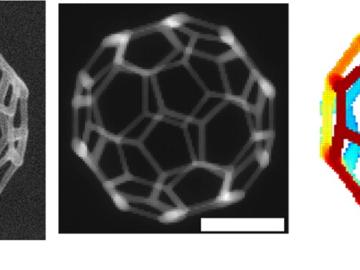

Designing a 3-D printed structure is hard enough when the product is inches or feet in size. Imagine shrinking it smaller than a drop of water, smaller even than a human hair, until it is dwarfed by a common bacterium.

This impossibly small structure can be made a reality with fo...