Filter News

Area of Research

- (-) Clean Energy (35)

- (-) Materials (11)

- (-) Neutron Science (6)

- Advanced Manufacturing (7)

- Biology and Environment (3)

- Building Technologies (1)

- Computational Engineering (1)

- Fusion and Fission (1)

- Isotopes (1)

- Materials for Computing (8)

- National Security (3)

- Nuclear Science and Technology (1)

- Sensors and Controls (1)

- Supercomputing (5)

- Transportation Systems (1)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (23)

- (-) Artificial Intelligence (1)

- (-) Biomedical (4)

- (-) Composites (6)

- (-) Cybersecurity (1)

- (-) Materials Science (12)

- (-) Security (1)

- (-) Transportation (12)

- Big Data (2)

- Bioenergy (4)

- Biology (5)

- Biotechnology (1)

- Buildings (7)

- Chemical Sciences (1)

- Clean Water (1)

- Climate Change (3)

- Computer Science (7)

- Coronavirus (2)

- Critical Materials (7)

- Decarbonization (2)

- Energy Storage (14)

- Environment (8)

- Frontier (1)

- Fusion (2)

- Grid (7)

- High-Performance Computing (2)

- Isotopes (3)

- ITER (1)

- Materials (19)

- Mathematics (1)

- Mercury (1)

- Microscopy (6)

- Nanotechnology (10)

- Net Zero (1)

- Neutron Science (13)

- Nuclear Energy (1)

- Physics (4)

- Polymers (4)

- Quantum Computing (1)

- Quantum Science (3)

- Space Exploration (3)

- Statistics (1)

- Summit (1)

- Sustainable Energy (20)

Media Contacts

Three technologies developed by ORNL researchers have won National Technology Transfer Awards from the Federal Laboratory Consortium. One of the awards went to a team that adapted melt-blowing capabilities at DOE’s Carbon Fiber Technology Facility to enable the production of filter material for N95 masks in the fight against COVID-19.

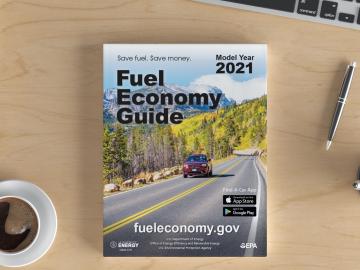

Fuel economy can take a tumble when temperatures plummet, according to the Department of Energy’s 2021 Fuel Economy Guide. Compiled by researchers at Oak Ridge National Laboratory, the guide includes several tips to improve a vehicle’s fuel performance.

Algorithms developed at Oak Ridge National Laboratory can greatly enhance X-ray computed tomography images of 3D-printed metal parts, resulting in more accurate, faster scans.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

![2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg 2018-P07635 BL-6 user - Univ of Guelph-6004R_sm[2].jpg](/sites/default/files/styles/list_page_thumbnail/public/2018-P07635%20BL-6%20user%20-%20Univ%20of%20Guelph-6004R_sm%5B2%5D.jpg?itok=DUdZNt_q)

A team of scientists, led by University of Guelph professor John Dutcher, are using neutrons at ORNL’s Spallation Neutron Source to unlock the secrets of natural nanoparticles that could be used to improve medicines.

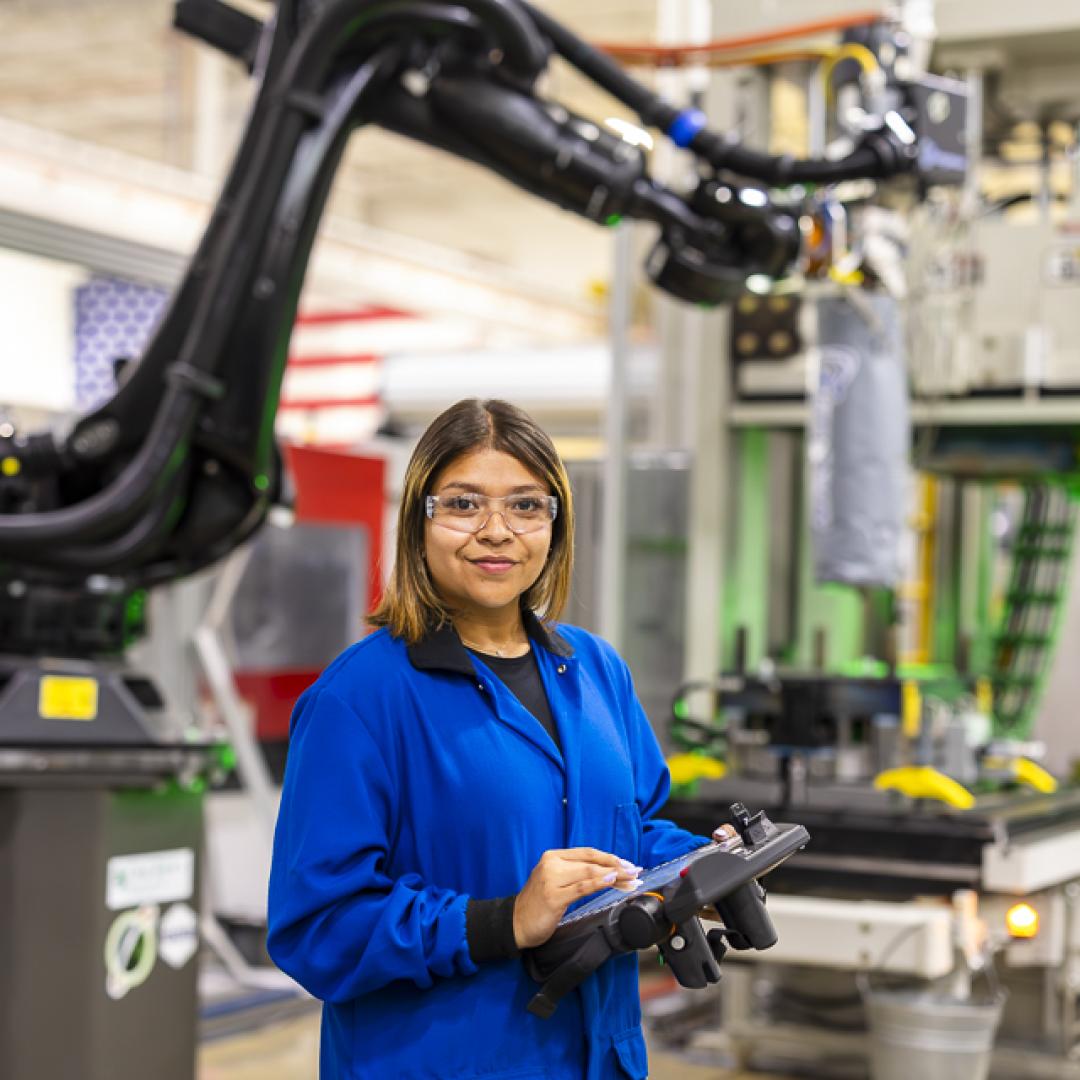

Two leaders in US manufacturing innovation, Thomas Kurfess and Scott Smith, are joining the Department of Energy’s Oak Ridge National Laboratory to support its pioneering research in advanced manufacturing.

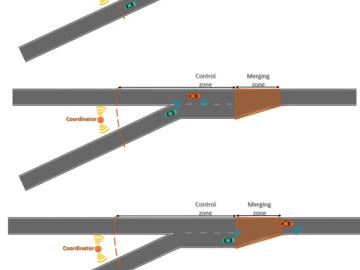

Self-driving cars promise to keep traffic moving smoothly and reduce fuel usage, but proving those advantages has been a challenge with so few connected and automated vehicles, or CAVs, currently on the road.

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...