Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (8)

- (-) Artificial Intelligence (4)

- (-) Bioenergy (5)

- (-) Cybersecurity (1)

- (-) Microscopy (8)

- (-) Polymers (7)

- Advanced Reactors (1)

- Biology (4)

- Biomedical (5)

- Buildings (1)

- Chemical Sciences (11)

- Clean Water (1)

- Climate Change (1)

- Composites (4)

- Computer Science (6)

- Coronavirus (3)

- Critical Materials (4)

- Decarbonization (3)

- Energy Storage (13)

- Environment (3)

- Exascale Computing (1)

- Frontier (1)

- Fusion (1)

- Grid (2)

- High-Performance Computing (3)

- Isotopes (7)

- Machine Learning (1)

- Materials (28)

- Materials Science (16)

- Nanotechnology (13)

- National Security (2)

- Neutron Science (6)

- Nuclear Energy (3)

- Partnerships (4)

- Physics (8)

- Quantum Science (3)

- Security (2)

- Simulation (1)

- Space Exploration (2)

- Sustainable Energy (2)

- Transformational Challenge Reactor (1)

- Transportation (3)

Media Contacts

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.

Researchers at ORNL are teaching microscopes to drive discoveries with an intuitive algorithm, developed at the lab’s Center for Nanophase Materials Sciences, that could guide breakthroughs in new materials for energy technologies, sensing and computing.

A study led by researchers at ORNL could help make materials design as customizable as point-and-click.

Tackling the climate crisis and achieving an equitable clean energy future are among the biggest challenges of our time.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

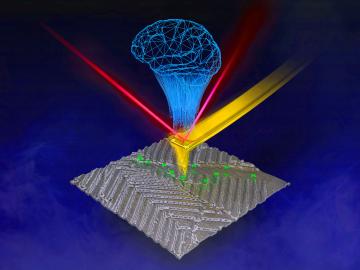

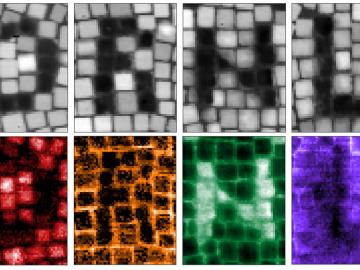

Drilling with the beam of an electron microscope, scientists at ORNL precisely machined tiny electrically conductive cubes that can interact with light and organized them in patterned structures that confine and relay light’s electromagnetic signal.

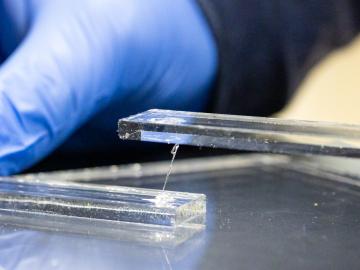

Researchers at ORNL used polymer chemistry to transform a common household plastic into a reusable adhesive with a rare combination of strength and ductility, making it one of the toughest materials ever reported.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

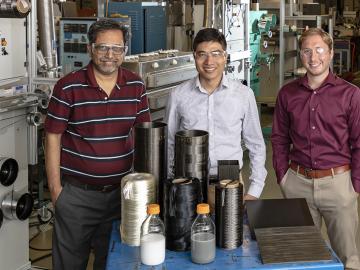

Carbon fiber composites—lightweight and strong—are great structural materials for automobiles, aircraft and other transportation vehicles. They consist of a polymer matrix, such as epoxy, into which reinforcing carbon fibers have been embedded. Because of differences in the mecha...

An Oak Ridge National Laboratory-led team used a scanning transmission electron microscope to selectively position single atoms below a crystal’s surface for the first time.