Filter News

Area of Research

- (-) Clean Energy (110)

- (-) Materials (71)

- Advanced Manufacturing (8)

- Biological Systems (2)

- Biology and Environment (24)

- Climate and Environmental Systems (3)

- Computer Science (2)

- Data (1)

- Energy Sciences (1)

- Fossil Energy (1)

- Fusion and Fission (5)

- Fusion Energy (5)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials for Computing (5)

- National Security (12)

- Neutron Science (44)

- Nuclear Science and Technology (28)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (3)

- Sensors and Controls (1)

- Supercomputing (55)

- Transportation Systems (1)

News Topics

- 3-D Printing/Advanced Manufacturing (22)

- Advanced Reactors (4)

- Artificial Intelligence (4)

- Big Data (4)

- Bioenergy (10)

- Biology (1)

- Biomedical (3)

- Biotechnology (1)

- Chemical Sciences (2)

- Clean Water (1)

- Climate Change (7)

- Composites (2)

- Computer Science (15)

- Coronavirus (8)

- Critical Materials (2)

- Cybersecurity (2)

- Decarbonization (1)

- Energy Storage (20)

- Environment (20)

- Exascale Computing (2)

- Grid (6)

- High-Performance Computing (1)

- Isotopes (1)

- Machine Learning (6)

- Materials (2)

- Materials Science (34)

- Mathematics (2)

- Mercury (1)

- Microscopy (7)

- Molten Salt (1)

- Nanotechnology (13)

- National Security (1)

- Neutron Science (14)

- Nuclear Energy (5)

- Physics (8)

- Polymers (6)

- Quantum Science (5)

- Security (1)

- Summit (4)

- Sustainable Energy (21)

- Transformational Challenge Reactor (4)

- Transportation (14)

Media Contacts

Oak Ridge National Laboratory today welcomed the first cohort of innovators to join Innovation Crossroads, the Southeast region's first entrepreneurial research and development program based at a U.S. Department of Energy national laboratory. Innovation Crossroads, ...

Five small companies have been selected to partner with the Department of Energy’s Oak Ridge National Laboratory to move technologies in commercial refrigeration systems, water power generation, bioenergy and battery manufacturing

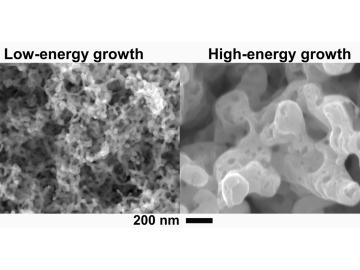

Scientists at Oak Ridge National Laboratory are using the precision of an electron beam to instantly adhere cathode coatings for lithium-ion batteries—a leap in efficiency that saves energy, reduces production and capital costs, and eliminates the use of toxic solvents.

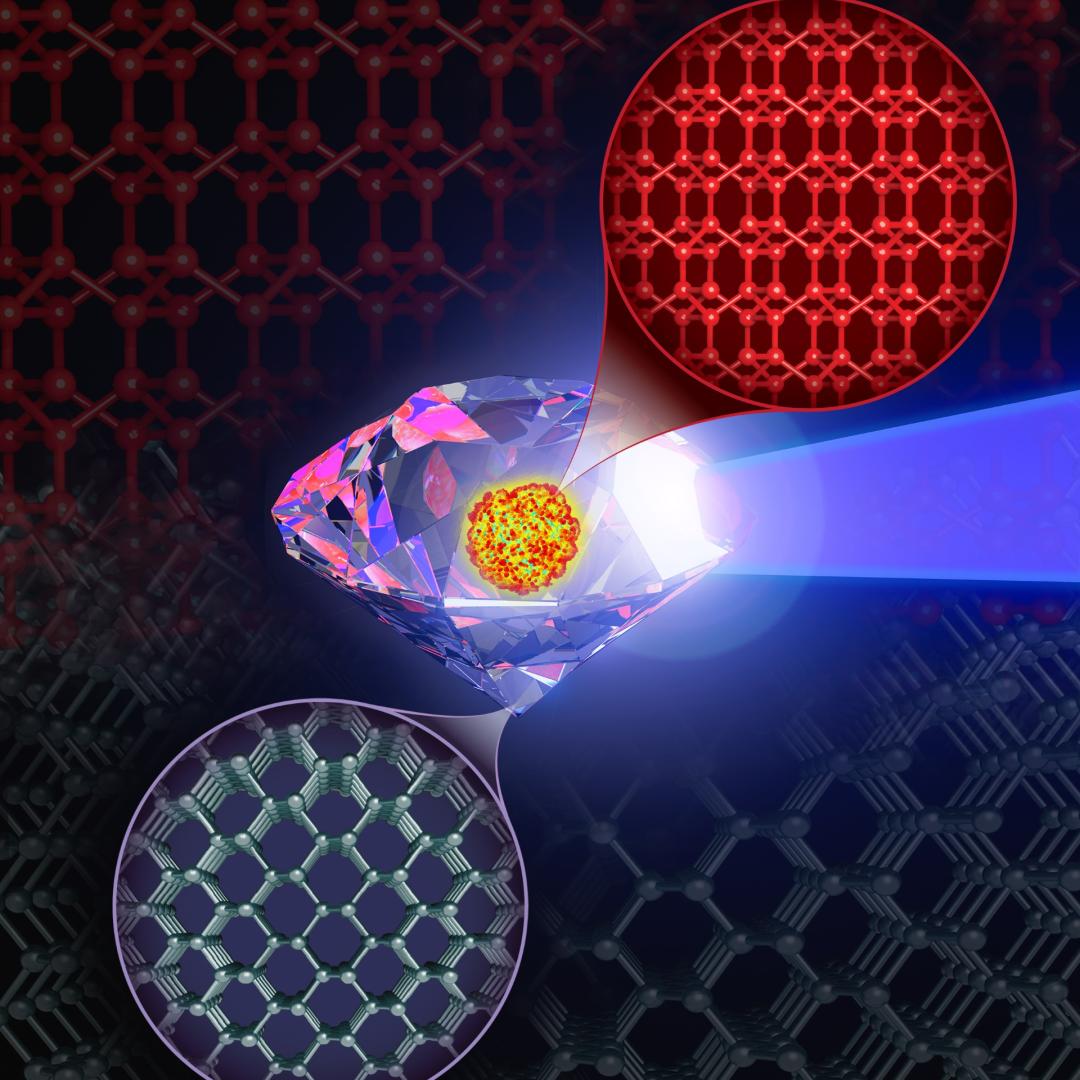

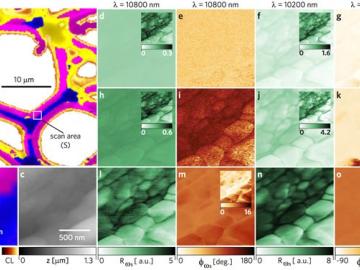

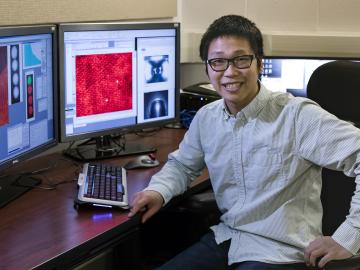

Researchers have long sought electrically conductive materials for economical energy-storage devices. Two-dimensional (2D) ceramics called MXenes are contenders. Unlike most 2D ceramics, MXenes have inherently good conductivity because they are molecular sheets made from the carbides ...

HTS International Corporation and the Department of Energy’s Oak Ridge National Laboratory have signed an agreement to explore potential collaborations in advanced manufacturing research.