Filter News

Area of Research

News Type

Date

Media Contacts

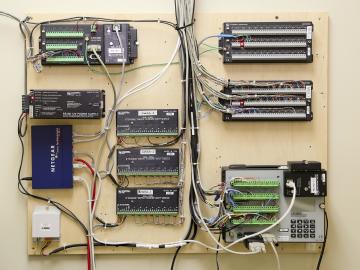

Ways to give homeowners more centralized control over how much electricity their home uses—from the air conditioning unit to the heat pump water heater—are being developed by Oak Ridge National Laboratory. An ORNL team is working with Southern Company and Alabama Power on its Sma...

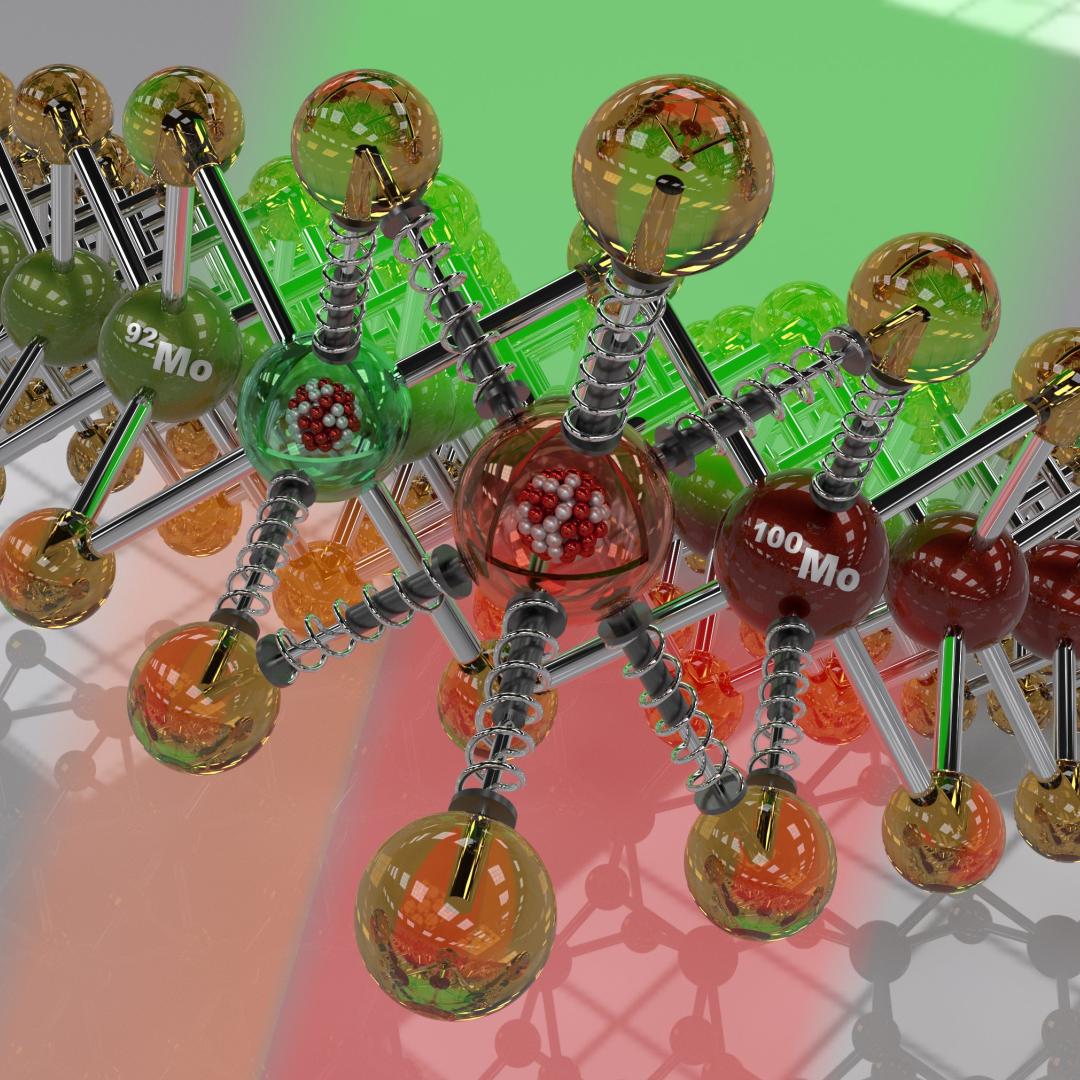

In response to the nuclear industry’s growing interest in molten salt reactors, Oak Ridge National Laboratory will bring together leading experts from around the world to discuss recent developments at its third annual MSR Workshop, October 3–4. This year’s theme will be key tech...

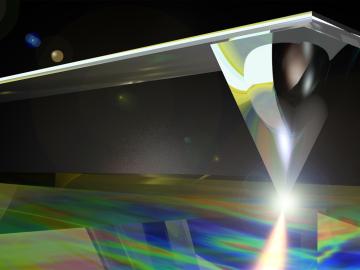

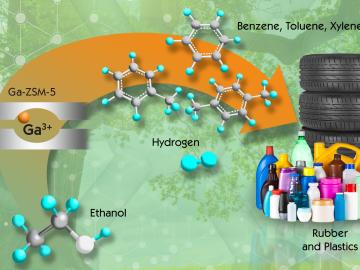

A simplified catalyst production process developed by Oak Ridge National Laboratory could double the output of high-value chemicals used in making materials found in soda bottles and tires. Scientists found that single gallium cations are the key to increasing production of ben...

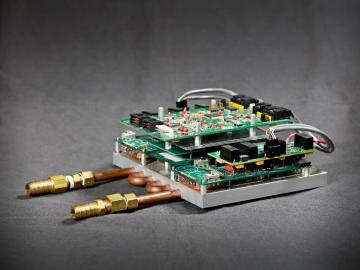

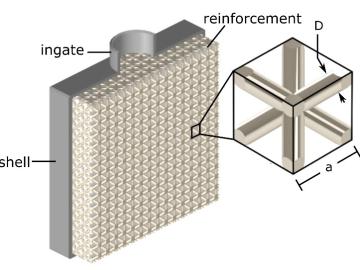

A new manufacturing method created by Oak Ridge National Laboratory and Rice University combines 3D printing with traditional casting to produce damage-tolerant components composed of multiple materials. Composite components made by pouring an aluminum alloy over a printed steel lattice showed an order of magnitude greater damage tolerance than aluminum alone.