Filter News

Area of Research

- (-) Clean Energy (41)

- (-) Neutron Science (17)

- Advanced Manufacturing (4)

- Biological Systems (2)

- Biology and Environment (7)

- Climate and Environmental Systems (1)

- Data (1)

- Fossil Energy (1)

- Isotope Development and Production (1)

- Materials (21)

- Nuclear Science and Technology (6)

- Sensors and Controls (1)

- Supercomputing (17)

- Transportation Systems (1)

Media Contacts

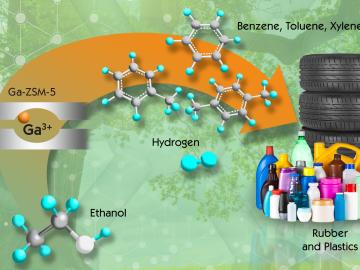

A simplified catalyst production process developed by Oak Ridge National Laboratory could double the output of high-value chemicals used in making materials found in soda bottles and tires. Scientists found that single gallium cations are the key to increasing production of ben...

Researchers used neutrons to probe a running engine at ORNL’s Spallation Neutron Source

Finding new energy uses for underrated materials is a recurring theme across Amit Naskar’s research portfolio. Since joining Oak Ridge National Laboratory in 2006, he has studied low-cost polymers as carbon fiber precursors, turning lignin−a byproduct of biofuel production−into renewable thermoplastics and creating carbon battery electrodes from recycled tires.

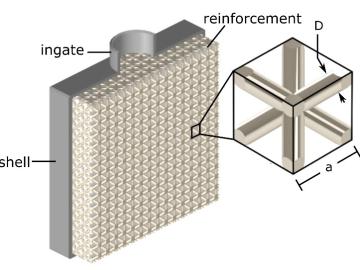

A new manufacturing method created by Oak Ridge National Laboratory and Rice University combines 3D printing with traditional casting to produce damage-tolerant components composed of multiple materials. Composite components made by pouring an aluminum alloy over a printed steel lattice showed an order of magnitude greater damage tolerance than aluminum alone.

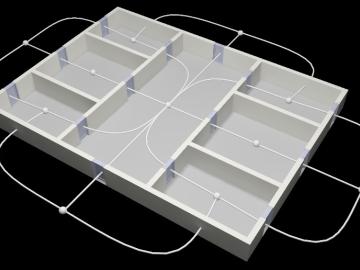

A new tool developed at Oak Ridge National Laboratory can help homeowners and builders calculate energy loss when air leaks through a building’s envelope, the physical barrier separating the interior and exterior. Starting with specific building metrics, the calculator analyzes multiz...

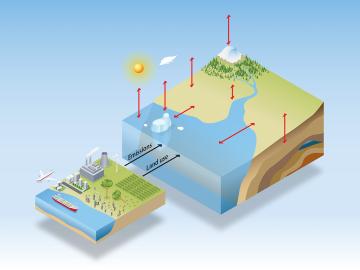

A new integrated computational model reduces uncertainty in climate predictions by bridging Earth systems with energy and economic models and large-scale human impact data. Co-developed by Oak Ridge National Laboratory, the novel integrated Earth system model, or iESM, leverages the power of supercomputers, including ORNL’s Titan, to couple biospheric feedbacks from oceans, atmosphere and land with human activity, such as fossil fuel emissions, agriculture and land use.