Filter News

Area of Research

News Type

News Topics

- (-) Advanced Reactors (1)

- (-) Artificial Intelligence (19)

- (-) Climate Change (18)

- (-) Fusion (8)

- (-) Microscopy (5)

- (-) Partnerships (6)

- (-) Quantum Science (5)

- (-) Security (1)

- 3-D Printing/Advanced Manufacturing (12)

- Big Data (11)

- Bioenergy (14)

- Biology (17)

- Biomedical (6)

- Biotechnology (2)

- Buildings (7)

- Chemical Sciences (11)

- Clean Water (7)

- Composites (2)

- Computer Science (28)

- Coronavirus (1)

- Critical Materials (2)

- Cybersecurity (6)

- Decarbonization (18)

- Emergency (1)

- Energy Storage (13)

- Environment (40)

- Exascale Computing (13)

- Fossil Energy (2)

- Frontier (14)

- Grid (11)

- High-Performance Computing (18)

- Hydropower (2)

- Isotopes (8)

- Machine Learning (12)

- Materials (22)

- Materials Science (13)

- Mathematics (2)

- Mercury (2)

- Microelectronics (2)

- Nanotechnology (6)

- National Security (17)

- Net Zero (3)

- Neutron Science (23)

- Nuclear Energy (21)

- Physics (13)

- Polymers (3)

- Quantum Computing (6)

- Renewable Energy (1)

- Simulation (19)

- Software (1)

- Space Exploration (5)

- Summit (11)

- Sustainable Energy (10)

- Transportation (8)

Media Contacts

Neutron experiments can take days to complete, requiring researchers to work long shifts to monitor progress and make necessary adjustments. But thanks to advances in artificial intelligence and machine learning, experiments can now be done remotely and in half the time.

Madhavi Martin brings a physicist’s tools and perspective to biological and environmental research at the Department of Energy’s Oak Ridge National Laboratory, supporting advances in bioenergy, soil carbon storage and environmental monitoring, and even helping solve a murder mystery.

ORNL hosted its fourth Artificial Intelligence for Robust Engineering and Science, or AIRES, workshop from April 18-20. Over 100 attendees from government, academia and industry convened to identify research challenges and investment areas, carving the future of the discipline.

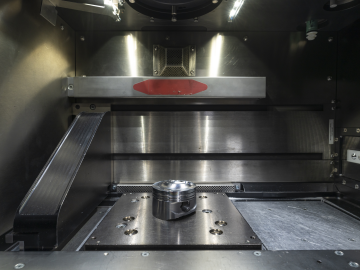

Dean Pierce of ORNL and a research team led by ORNL’s Alex Plotkowski were honored by DOE’s Vehicle Technologies Office for development of novel high-performance alloys that can withstand extreme environments.

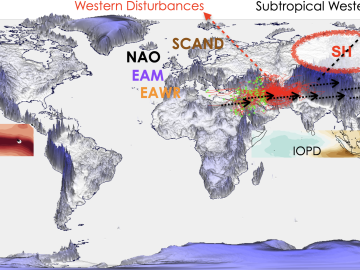

Wildfires have shaped the environment for millennia, but they are increasing in frequency, range and intensity in response to a hotter climate. The phenomenon is being incorporated into high-resolution simulations of the Earth’s climate by scientists at the Department of Energy’s Oak Ridge National Laboratory, with a mission to better understand and predict environmental change.

When geoinformatics engineering researchers at the Department of Energy’s Oak Ridge National Laboratory wanted to better understand changes in land areas and points of interest around the world, they turned to the locals — their data, at least.

As extreme weather devastates communities worldwide, scientists are using modeling and simulation to understand how climate change impacts the frequency and intensity of these events. Although long-term climate projections and models are important, they are less helpful for short-term prediction of extreme weather that may rapidly displace thousands of people or require emergency aid.

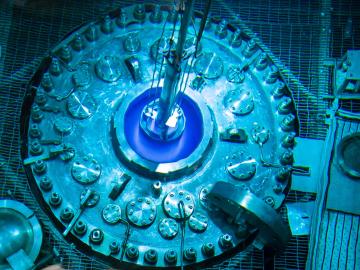

Creating energy the way the sun and stars do — through nuclear fusion — is one of the grand challenges facing science and technology. What’s easy for the sun and its billions of relatives turns out to be particularly difficult on Earth.

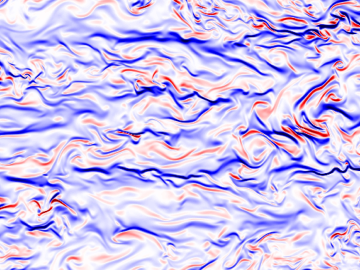

Simulations performed on the Summit supercomputer at ORNL revealed new insights into the role of turbulence in mixing fluids and could open new possibilities for projecting climate change and studying fluid dynamics.

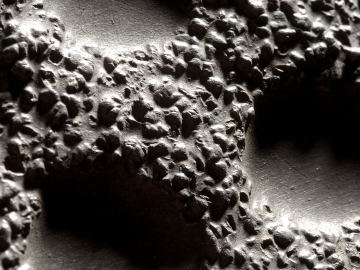

For more than 100 years, Magotteaux has provided grinding materials and castings for the mining, cement and aggregates industries. The company, based in Belgium, began its international expansion in 1968. Its second international plant has been a critical part of the Pulaski, Tennessee, economy since 1972.