Filter News

Area of Research

- Advanced Manufacturing (8)

- Biological Systems (3)

- Biology and Environment (8)

- Building Technologies (3)

- Clean Energy (108)

- Climate and Environmental Systems (4)

- Computational Biology (1)

- Computational Engineering (1)

- Computer Science (8)

- Energy Frontier Research Centers (1)

- Fossil Energy (1)

- Fuel Cycle Science and Technology (1)

- Fusion Energy (7)

- Materials (107)

- National Security (7)

- Neutron Science (49)

- Nuclear Science and Technology (25)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (3)

- Sensors and Controls (2)

- Supercomputing (54)

- Transportation Systems (1)

Date

News Topics

- 3-D Printing/Advanced Manufacturing (20)

- Advanced Reactors (8)

- Artificial Intelligence (13)

- Big Data (8)

- Bioenergy (11)

- Biology (1)

- Biomedical (9)

- Biotechnology (1)

- Clean Water (6)

- Climate Change (1)

- Composites (5)

- Computer Science (49)

- Critical Materials (1)

- Cybersecurity (8)

- Energy Storage (10)

- Environment (22)

- Exascale Computing (2)

- Frontier (2)

- Fusion (9)

- Grid (8)

- Isotopes (7)

- Machine Learning (5)

- Materials Science (30)

- Mercury (2)

- Microscopy (10)

- Molten Salt (5)

- Nanotechnology (15)

- Neutron Science (26)

- Nuclear Energy (27)

- Physics (15)

- Polymers (7)

- Quantum Science (13)

- Security (9)

- Space Exploration (6)

- Summit (11)

- Sustainable Energy (8)

- Transportation (19)

Media Contacts

A futuristic experiment simulating warmer environmental conditions has shown that peatland vegetation responds to higher temperatures with an earlier and longer growth period.

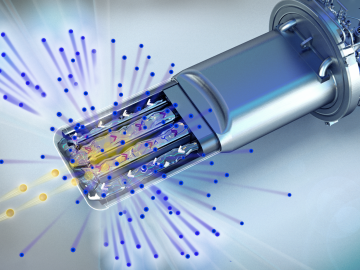

The materials inside a fusion reactor must withstand one of the most extreme environments in science, with temperatures in the thousands of degrees Celsius and a constant bombardment of neutron radiation and deuterium and tritium, isotopes of hydrogen, from the volatile plasma at th...

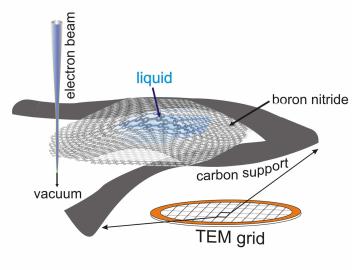

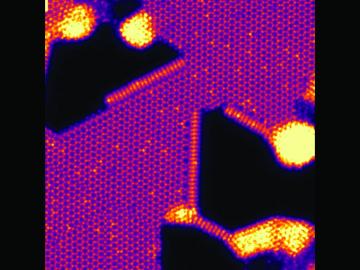

A new microscopy technique developed at the University of Illinois at Chicago allows researchers to visualize liquids at the nanoscale level — about 10 times more resolution than with traditional transmission electron microscopy — for the first time. By trapping minute amounts of...

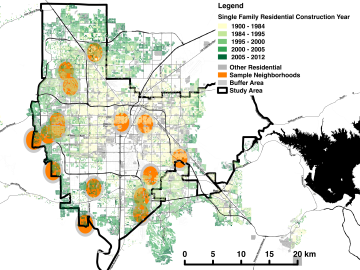

A team led by Oak Ridge National Laboratory has discovered that residents living in arid environments share a desire for water security, which can ultimately benefit entire neighborhoods. Las Vegas, Nevada’s water utility was the first utility in the United States to implement ...

The construction industry may soon benefit from 3D printed molds to make concrete facades, promising lower cost and production time. Researchers at Oak Ridge National Laboratory are evaluating the performance of 3D printed molds used to precast concrete facades in a 42-story buildin...

An Oak Ridge National Laboratory–led team has learned how to engineer tiny pores embellished with distinct edge structures inside atomically-thin two-dimensional, or 2D, crystals. The 2D crystals are envisioned as stackable building blocks for ultrathin electronics and other advance...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...