Filter News

Area of Research

- Advanced Manufacturing (6)

- Biology and Environment (4)

- Building Technologies (1)

- Clean Energy (35)

- Computer Science (2)

- Energy Sciences (1)

- Fusion and Fission (1)

- Materials (15)

- Materials for Computing (4)

- National Security (1)

- Neutron Science (3)

- Nuclear Science and Technology (4)

- Supercomputing (4)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (33)

- (-) Energy Storage (23)

- Advanced Reactors (15)

- Artificial Intelligence (9)

- Big Data (12)

- Bioenergy (14)

- Biology (6)

- Biomedical (25)

- Biotechnology (2)

- Buildings (1)

- Chemical Sciences (5)

- Clean Water (3)

- Climate Change (11)

- Composites (4)

- Computer Science (53)

- Coronavirus (23)

- Critical Materials (3)

- Cybersecurity (7)

- Decarbonization (1)

- Environment (32)

- Exascale Computing (3)

- Frontier (1)

- Fusion (17)

- Grid (10)

- High-Performance Computing (3)

- Isotopes (14)

- Machine Learning (8)

- Materials (2)

- Materials Science (47)

- Mathematics (2)

- Mercury (2)

- Microscopy (13)

- Molten Salt (6)

- Nanotechnology (26)

- National Security (2)

- Neutron Science (38)

- Nuclear Energy (41)

- Physics (22)

- Polymers (12)

- Quantum Science (17)

- Security (10)

- Space Exploration (4)

- Summit (19)

- Sustainable Energy (24)

- Transformational Challenge Reactor (5)

- Transportation (22)

Media Contacts

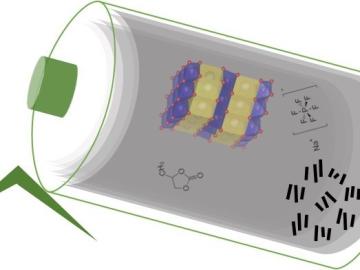

Researchers at ORNL demonstrated that sodium-ion batteries can serve as a low-cost, high performance substitute for rechargeable lithium-ion batteries commonly used in robotics, power tools, and grid-scale energy storage.

Energy storage startup SPARKZ Inc. has exclusively licensed five battery technologies from the Department of Energy’s Oak Ridge National Laboratory designed to eliminate cobalt metal in lithium-ion batteries. The advancement is aimed at accelerating the production of electric vehicles and energy storage solutions for the power grid.

Peter Wang is focused on robotics and automation at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, working on high-profile projects such as the MedUSA, a large-scale hybrid additive manufacturing machine.

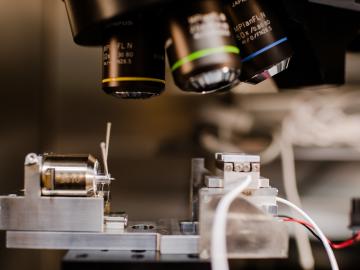

The formation of lithium dendrites is still a mystery, but materials engineers study the conditions that enable dendrites and how to stop them.

Rigoberto “Gobet” Advincula has been named Governor’s Chair of Advanced and Nanostructured Materials at Oak Ridge National Laboratory and the University of Tennessee.

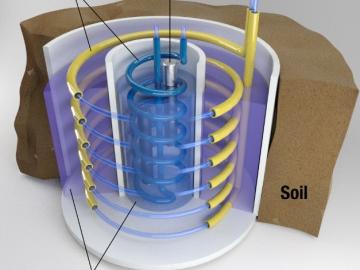

Oak Ridge National Laboratory researchers created a geothermal energy storage system that could reduce peak electricity demand up to 37% in homes while helping balance grid operations.

To better determine the potential energy cost savings among connected homes, researchers at Oak Ridge National Laboratory developed a computer simulation to more accurately compare energy use on similar weather days.

Scientists at the Department of Energy’s Oak Ridge National Laboratory have created a recipe for a renewable 3D printing feedstock that could spur a profitable new use for an intractable biorefinery byproduct: lignin.

Two leaders in US manufacturing innovation, Thomas Kurfess and Scott Smith, are joining the Department of Energy’s Oak Ridge National Laboratory to support its pioneering research in advanced manufacturing.

The next cohort of Innovation Crossroads fellows at Oak Ridge National Laboratory will receive support from the U.S. Department of Energy’s Advanced Manufacturing Office (AMO) and the Tennessee Valley Authority (TVA). Officials made the announcement today at th...