Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (21)

- (-) National Security (18)

- Advanced Reactors (4)

- Artificial Intelligence (26)

- Big Data (14)

- Bioenergy (13)

- Biology (14)

- Biomedical (10)

- Biotechnology (6)

- Buildings (14)

- Chemical Sciences (16)

- Clean Water (5)

- Climate Change (22)

- Composites (9)

- Computer Science (38)

- Critical Materials (7)

- Cybersecurity (3)

- Decarbonization (21)

- Education (1)

- Emergency (1)

- Energy Storage (11)

- Environment (24)

- Exascale Computing (7)

- Fossil Energy (3)

- Frontier (8)

- Fusion (10)

- Grid (12)

- High-Performance Computing (17)

- Isotopes (17)

- ITER (1)

- Machine Learning (9)

- Materials (14)

- Materials Science (26)

- Mathematics (4)

- Mercury (1)

- Microelectronics (1)

- Microscopy (7)

- Molten Salt (4)

- Nanotechnology (11)

- Net Zero (6)

- Neutron Science (18)

- Nuclear Energy (20)

- Partnerships (15)

- Physics (15)

- Polymers (10)

- Quantum Computing (11)

- Quantum Science (15)

- Security (9)

- Simulation (14)

- Space Exploration (5)

- Statistics (2)

- Summit (8)

- Sustainable Energy (20)

- Transportation (19)

Media Contacts

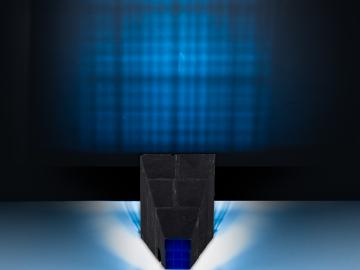

Simulations performed on the Summit supercomputer at ORNL are cutting through that time and expense by helping researchers digitally customize the ideal alloy.

Rishi Pillai and his research team from ORNL will receive a Best Paper award from the American Society of Mechanical Engineers International Gas Turbine Institute in June at the Turbo Expo 2024 in London.

The Society of Manufacturing Engineers has honored three Oak Ridge National Laboratory researchers with the 2024 SME Susan Smyth Outstanding Young Manufacturing Engineer Award.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

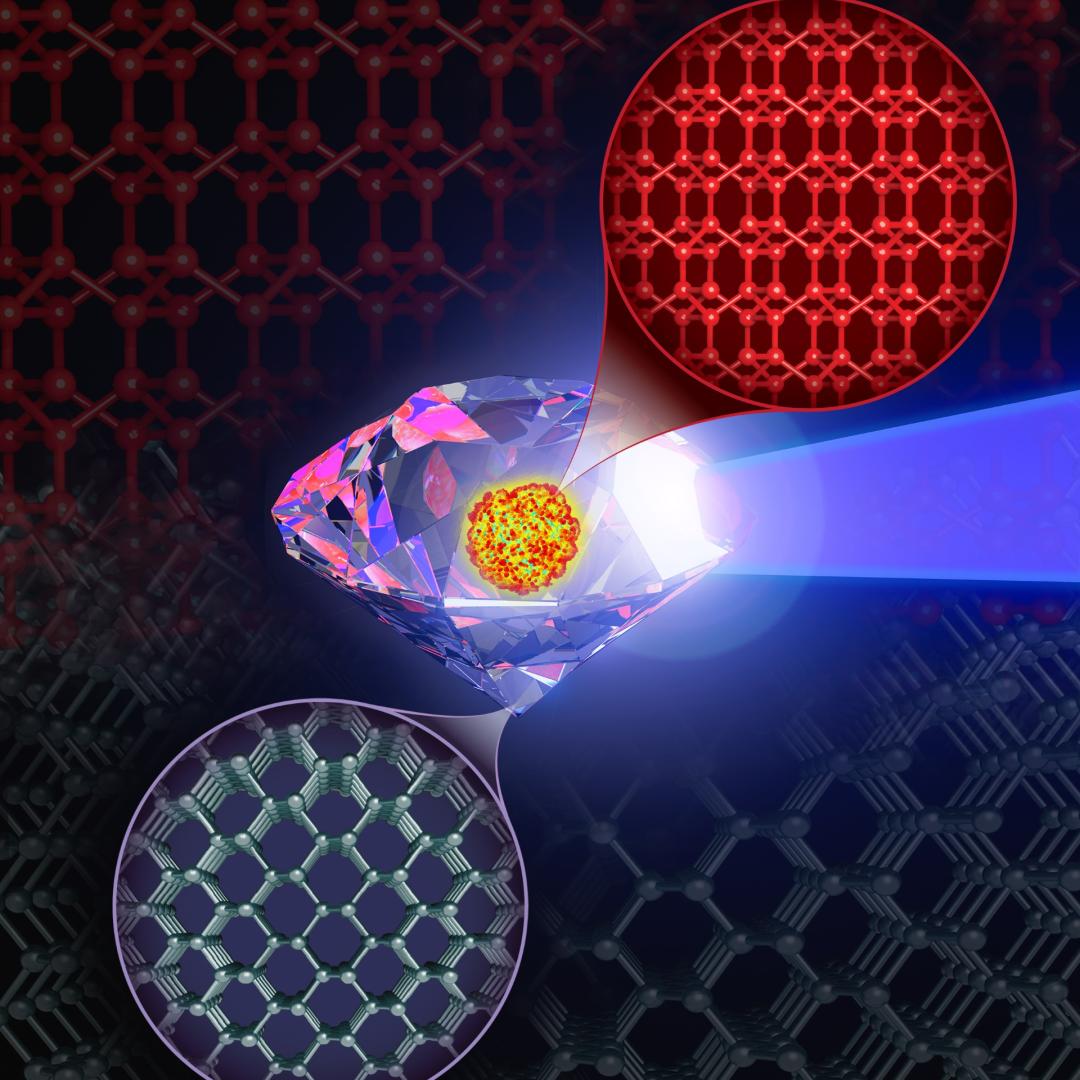

Nuclear nonproliferation scientists at ORNL have published the Compendium of Uranium Raman and Infrared Experimental Spectra, a public database and analysis of structure-spectral relationships for uranium minerals. This first-of-its-kind dataset and corresponding analysis fill a key gap in the existing body of knowledge for mineralogists and actinide scientists.

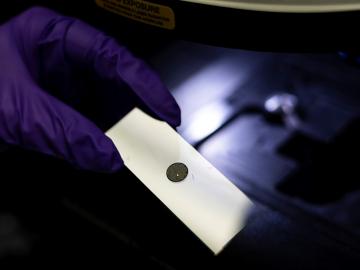

Scientists at ORNL have developed 3-D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments

ORNL’s Assaf Anyamba has spent his career using satellite images to determine where extreme weather may lead to vector-borne disease outbreaks. His work has helped the U.S. government better prepare for outbreaks that happen during periods of extended weather events such as El Niño and La Niña, climate patterns in the Pacific Ocean that can affect weather worldwide.

ORNL scientists have determined how to avoid costly and potentially irreparable damage to large metallic parts fabricated through additive manufacturing, also known as 3D printing, that is caused by residual stress in the material.

Canan Karakaya, a R&D Staff member in the Chemical Process Scale-Up group at ORNL, was inspired to become a chemical engineer after she experienced a magical transformation that turned ammonia gas into ammonium nitrate, turning a liquid into white flakes gently floating through the air.

ORNL took home the top honors in three categories at the second annual DOE Geospatial Science Poster competition, held on National GIS Day. For the second year in a row, DOE awarded ORNL top prize as Best Geospatial Program. Additionally, ORNL geospatial researchers took home first place prizes for their posters in the Best Departmental Element Alignment and Best Cartography categories.