Filter News

Area of Research

- (-) Materials (24)

- Advanced Manufacturing (1)

- Biological Systems (1)

- Biology and Environment (3)

- Building Technologies (2)

- Clean Energy (35)

- Climate and Environmental Systems (1)

- Fossil Energy (1)

- Fusion Energy (1)

- National Security (2)

- Neutron Science (15)

- Nuclear Science and Technology (8)

- Sensors and Controls (1)

- Supercomputing (13)

News Type

Media Contacts

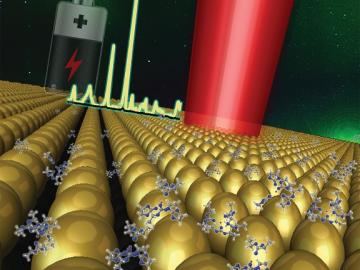

By studying the inner workings of lithium-ion batteries, Oak Ridge National Laboratory researchers have developed a highly sensitive technique to characterize and measure at the electrolyte and electrode interface.

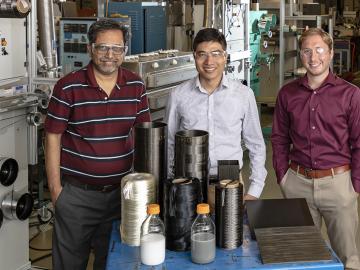

Carbon fiber composites—lightweight and strong—are great structural materials for automobiles, aircraft and other transportation vehicles. They consist of a polymer matrix, such as epoxy, into which reinforcing carbon fibers have been embedded. Because of differences in the mecha...

Physicists turned to the “doubly magic” tin isotope Sn-132, colliding it with a target at Oak Ridge National Laboratory to assess its properties as it lost a neutron to become Sn-131.

Lithium-ion batteries commonly used in consumer electronics are notorious for bursting into flame when damaged or improperly packaged. These incidents occasionally have grave consequences, including burns, house fires and at least one plane crash.

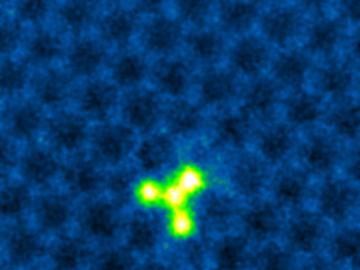

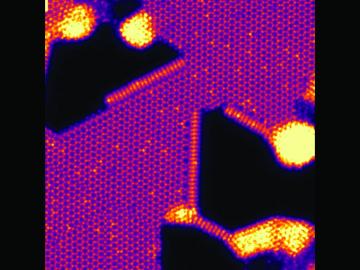

An Oak Ridge National Laboratory-led team used a scanning transmission electron microscope to selectively position single atoms below a crystal’s surface for the first time.

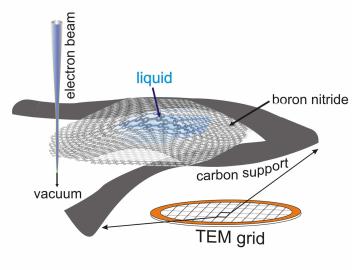

A new microscopy technique developed at the University of Illinois at Chicago allows researchers to visualize liquids at the nanoscale level — about 10 times more resolution than with traditional transmission electron microscopy — for the first time. By trapping minute amounts of...

An Oak Ridge National Laboratory–led team has learned how to engineer tiny pores embellished with distinct edge structures inside atomically-thin two-dimensional, or 2D, crystals. The 2D crystals are envisioned as stackable building blocks for ultrathin electronics and other advance...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...