Filter News

Area of Research

Media Contacts

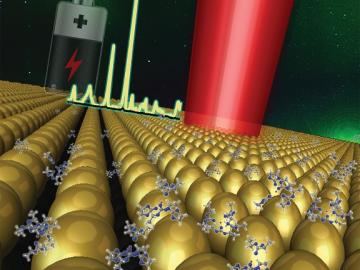

By studying the inner workings of lithium-ion batteries, Oak Ridge National Laboratory researchers have developed a highly sensitive technique to characterize and measure at the electrolyte and electrode interface.

Scientists from Oak Ridge National Laboratory performed a corrosion test in a neutron radiation field to support the continued development of molten salt reactors.

Physicists turned to the “doubly magic” tin isotope Sn-132, colliding it with a target at Oak Ridge National Laboratory to assess its properties as it lost a neutron to become Sn-131.

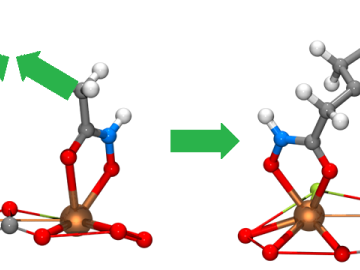

Scientists from the Critical Materials Institute used the Titan supercomputer and Eos computing cluster at ORNL to analyze designer molecules that could increase the yield of rare earth elements found in bastnaesite, an important mineral

An Oak Ridge National Laboratory-led team used a scanning transmission electron microscope to selectively position single atoms below a crystal’s surface for the first time.

Experts focused on the future of nuclear technology will gather at Oak Ridge National Laboratory for the fourth annual Molten Salt Reactor Workshop on October 3–4.

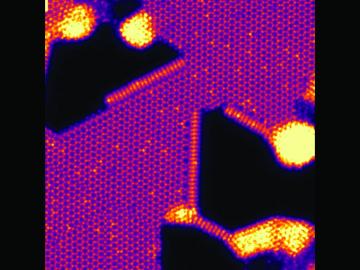

An Oak Ridge National Laboratory–led team has learned how to engineer tiny pores embellished with distinct edge structures inside atomically-thin two-dimensional, or 2D, crystals. The 2D crystals are envisioned as stackable building blocks for ultrathin electronics and other advance...

Oak Ridge National Laboratory scientists have improved a mixture of materials used to 3D print permanent magnets with increased density, which could yield longer lasting, better performing magnets for electric motors, sensors and vehicle applications. Building on previous research, ...