Filter News

Area of Research

- Advanced Manufacturing (5)

- Biology and Environment (2)

- Building Technologies (1)

- Clean Energy (24)

- Computational Engineering (1)

- Computer Science (4)

- Fusion and Fission (4)

- Fusion Energy (9)

- Materials (12)

- Materials for Computing (1)

- National Security (1)

- Neutron Science (4)

- Nuclear Science and Technology (17)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (4)

- Supercomputing (10)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (26)

- (-) Advanced Reactors (16)

- (-) Clean Water (7)

- (-) Fusion (17)

- (-) Machine Learning (9)

- (-) Molten Salt (6)

- (-) Quantum Science (11)

- Artificial Intelligence (15)

- Big Data (16)

- Bioenergy (10)

- Biology (5)

- Biomedical (22)

- Biotechnology (2)

- Chemical Sciences (2)

- Climate Change (6)

- Composites (2)

- Computer Science (57)

- Coronavirus (14)

- Critical Materials (1)

- Cybersecurity (5)

- Energy Storage (23)

- Environment (32)

- Exascale Computing (3)

- Frontier (1)

- Grid (13)

- High-Performance Computing (1)

- Isotopes (8)

- Materials Science (34)

- Mathematics (2)

- Mercury (3)

- Microscopy (9)

- Nanotechnology (12)

- Neutron Science (28)

- Nuclear Energy (42)

- Physics (13)

- Polymers (8)

- Security (5)

- Space Exploration (7)

- Summit (16)

- Sustainable Energy (15)

- Transformational Challenge Reactor (3)

- Transportation (25)

Media Contacts

Peter Wang is focused on robotics and automation at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, working on high-profile projects such as the MedUSA, a large-scale hybrid additive manufacturing machine.

A team from the ORNL has conducted a series of experiments to gain a better understanding of quantum mechanics and pursue advances in quantum networking and quantum computing, which could lead to practical applications in cybersecurity and other areas.

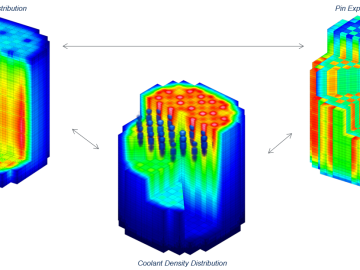

Nuclear scientists at Oak Ridge National Laboratory have established a Nuclear Quality Assurance-1 program for a software product designed to simulate today’s commercial nuclear reactors – removing a significant barrier for industry adoption of the technology.

While Tsouris’ water research is diverse in scope, its fundamentals are based on basic science principles that remain largely unchanged, particularly in a mature field like chemical engineering.

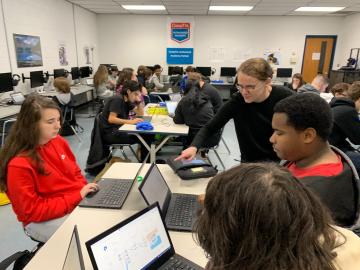

ORNL computer scientist Catherine Schuman returned to her alma mater, Harriman High School, to lead Hour of Code activities and talk to students about her job as a researcher.

Researchers at Oak Ridge National Laboratory demonstrated that an additively manufactured polymer layer, when applied to carbon fiber reinforced plastic, or CFRP, can serve as an effective protector against aircraft lightning strikes.

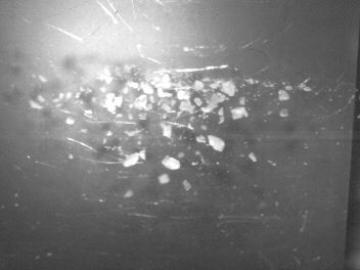

As scientists study approaches to best sustain a fusion reactor, a team led by Oak Ridge National Laboratory investigated injecting shattered argon pellets into a super-hot plasma, when needed, to protect the reactor’s interior wall from high-energy runaway electrons.

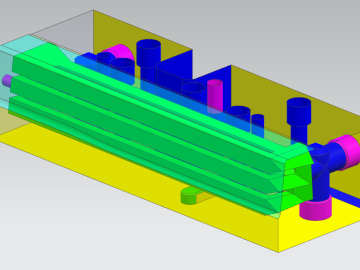

Researchers demonstrated that an additively manufactured hot stamping die can withstand up to 25,000 usage cycles, proving that this technique is a viable solution for production.

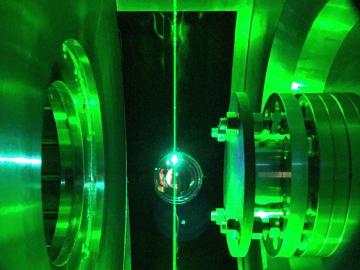

In a recent study, researchers at Oak Ridge National Laboratory performed experiments in a prototype fusion reactor materials testing facility to develop a method that uses microwaves to raise the plasma’s temperature closer to the extreme values

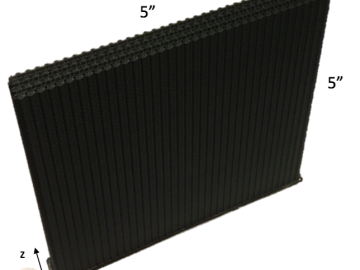

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.