Filter News

Area of Research

News Topics

- (-) Decarbonization (5)

- 3-D Printing/Advanced Manufacturing (9)

- Advanced Reactors (4)

- Artificial Intelligence (8)

- Big Data (1)

- Bioenergy (7)

- Biology (7)

- Biomedical (3)

- Biotechnology (1)

- Buildings (3)

- Chemical Sciences (9)

- Clean Water (1)

- Climate Change (2)

- Composites (1)

- Computer Science (14)

- Coronavirus (2)

- Critical Materials (1)

- Cybersecurity (8)

- Element Discovery (1)

- Energy Storage (16)

- Environment (9)

- Exascale Computing (4)

- Fossil Energy (1)

- Frontier (7)

- Fusion (5)

- Grid (7)

- High-Performance Computing (3)

- Isotopes (3)

- ITER (1)

- Machine Learning (4)

- Materials (16)

- Materials Science (15)

- Microscopy (4)

- Nanotechnology (6)

- National Security (7)

- Neutron Science (13)

- Nuclear Energy (8)

- Partnerships (6)

- Physics (9)

- Polymers (3)

- Quantum Computing (2)

- Quantum Science (9)

- Security (4)

- Space Exploration (1)

- Summit (4)

- Sustainable Energy (10)

- Transformational Challenge Reactor (2)

- Transportation (7)

Media Contacts

Researchers at ORNL have developed a new method for producing a key component of lithium-ion batteries. The result is a more affordable battery from a faster, less wasteful process that uses less toxic material.

As the United States shifts away from fossil-fuel-burning cars and trucks, scientists at the Department of Energy’s Oak Ridge and Argonne national laboratories are exploring options for another form of transportation: trains. The research focuses on zero-carbon hydrogen and other low-carbon fuels as viable alternatives to diesel for the rail industry.

ORNL researchers have developed an upcycling approach that adds value to discarded plastics for reuse in additive manufacturing, or 3D printing.

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

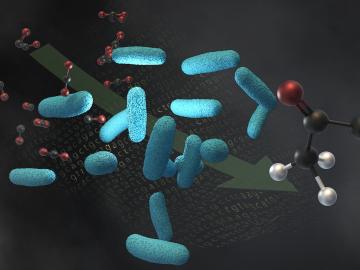

A team of scientists from LanzaTech, Northwestern University and ORNL have developed carbon capture technology that harnesses emissions from industrial processes to produce acetone and isopropanol