Filter News

Area of Research

- (-) Materials (24)

- Advanced Manufacturing (4)

- Biology and Environment (3)

- Building Technologies (1)

- Clean Energy (33)

- Climate and Environmental Systems (1)

- Computational Engineering (1)

- Computer Science (6)

- Fusion Energy (4)

- National Security (2)

- Neutron Science (9)

- Nuclear Science and Technology (9)

- Quantum information Science (2)

- Supercomputing (8)

- Transportation Systems (1)

News Type

News Topics

- 3-D Printing/Advanced Manufacturing (2)

- Advanced Reactors (1)

- Clean Water (1)

- Composites (1)

- Energy Storage (3)

- Environment (1)

- Fusion (2)

- Materials Science (11)

- Microscopy (3)

- Molten Salt (1)

- Nanotechnology (3)

- Neutron Science (3)

- Nuclear Energy (3)

- Physics (2)

- Polymers (2)

- Sustainable Energy (2)

- Transportation (4)

Media Contacts

Electric vehicles can drive longer distances if their lithium-ion batteries deliver more energy in a lighter package. A prime weight-loss candidate is the current collector, a component that often adds 10% to the weight of a battery cell without contributing energy.

Friederike Bock, a Eugene P. Wigner Fellow, wants everyone to know scientists aren’t just robots—they want to help others understand their research, and they have wide-ranging interests.

Researchers at Oak Ridge National Laboratory demonstrated that an additively manufactured polymer layer, when applied to carbon fiber reinforced plastic, or CFRP, can serve as an effective protector against aircraft lightning strikes.

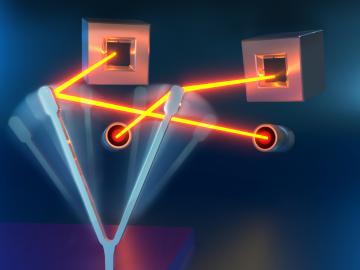

Researchers at ORNL and the National Renewable Energy Laboratory took inspiration from flying insects to demonstrate a miniaturized gyroscope, a special sensor used in navigation technologies.

Researchers at Oak Ridge National Laboratory will present eight innovative technologies currently available for commercialization during a public event at ORNL on October 17.

Researchers at Oak Ridge National Laboratory proved that a certain class of ionic liquids, when mixed with commercially available oils, can make gears run more efficiently with less noise and better durability.

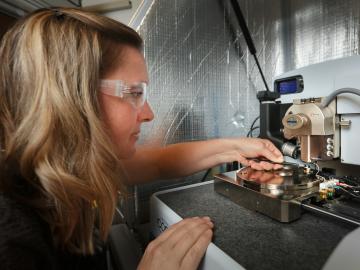

When Nina Balke came to the United States on a Feodor Lynen Fellowship for German scholars, her original plan was to complete a year abroad and return home to native opportunities in materials sciences.

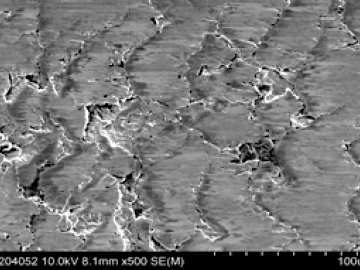

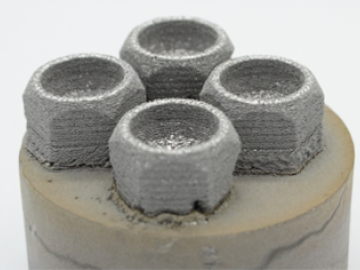

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

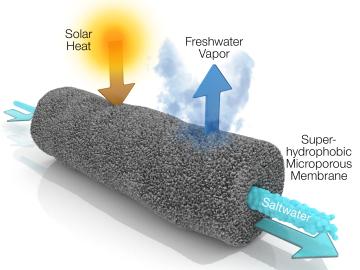

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

Raphaël Hermann of the Department of Energy’s Oak Ridge National Laboratory conducts experiments to better understand materials for energy and information applications.