Filter News

Area of Research

- (-) Materials (52)

- (-) National Security (8)

- Advanced Manufacturing (10)

- Biological Systems (1)

- Biology and Environment (18)

- Clean Energy (77)

- Climate and Environmental Systems (4)

- Computer Science (2)

- Fusion and Fission (4)

- Fusion Energy (7)

- Isotopes (3)

- Materials for Computing (3)

- Neutron Science (44)

- Nuclear Science and Technology (31)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (4)

- Supercomputing (36)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (9)

- (-) Bioenergy (5)

- (-) Biomedical (1)

- (-) Cybersecurity (5)

- (-) Environment (9)

- (-) Exascale Computing (1)

- (-) Microscopy (10)

- (-) Nanotechnology (18)

- (-) Neutron Science (14)

- (-) Nuclear Energy (11)

- Advanced Reactors (2)

- Artificial Intelligence (5)

- Big Data (4)

- Chemical Sciences (2)

- Clean Water (2)

- Climate Change (1)

- Composites (1)

- Computer Science (16)

- Coronavirus (2)

- Critical Materials (2)

- Energy Storage (13)

- Fusion (2)

- Grid (2)

- Isotopes (2)

- Machine Learning (4)

- Materials (1)

- Materials Science (48)

- Mathematics (1)

- Molten Salt (2)

- National Security (2)

- Physics (10)

- Polymers (6)

- Quantum Science (6)

- Security (4)

- Summit (3)

- Sustainable Energy (11)

- Transformational Challenge Reactor (2)

- Transportation (8)

Media Contacts

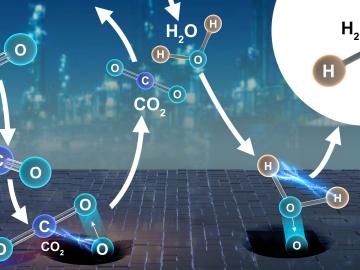

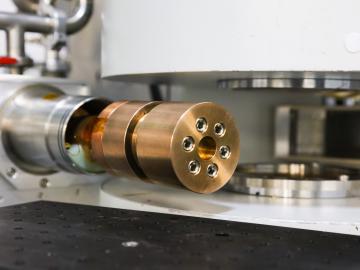

Collaborators at the Department of Energy’s Oak Ridge National Laboratory and U.S. universities used neutron scattering and other advanced characterization techniques to study how a prominent catalyst enables the “water-gas shift” reaction to purify and generate hydrogen at industrial scale.

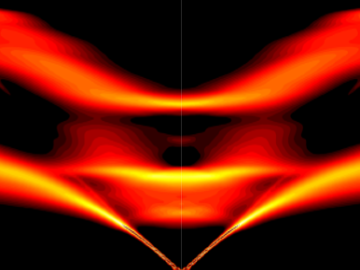

Researchers have pioneered a new technique using pressure to manipulate magnetism in thin film materials used to enhance performance in electronic devices.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

Scientists have discovered a way to alter heat transport in thermoelectric materials, a finding that may ultimately improve energy efficiency as the materials

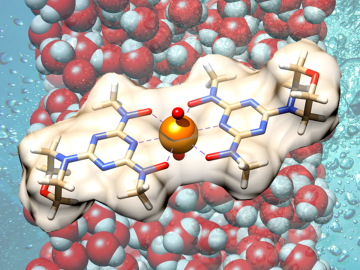

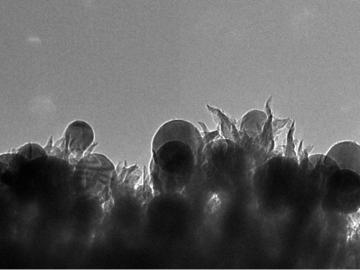

Scientists have demonstrated a new bio-inspired material for an eco-friendly and cost-effective approach to recovering uranium from seawater.

Researchers at the Department of Energy’s Oak Ridge National Laboratory, Pacific Northwest National Laboratory and Washington State University teamed up to investigate the complex dynamics of low-water liquids that challenge nuclear waste processing at federal cleanup sites.

Scientists at the Department of Energy’s Oak Ridge National Laboratory are working to understand both the complex nature of uranium and the various oxide forms it can take during processing steps that might occur throughout the nuclear fuel cycle.

Kevin Field at the Department of Energy’s Oak Ridge National Laboratory synthesizes and scrutinizes materials for nuclear power systems that must perform safely and efficiently over decades of irradiation.

OAK RIDGE, Tenn., March 22, 2019 – Karren Leslie More, a researcher at the Department of Energy’s Oak Ridge National Laboratory, has been elected fellow of the Microscopy Society of America (MSA) professional organization.

OAK RIDGE, Tenn., March 1, 2019—ReactWell, LLC, has licensed a novel waste-to-fuel technology from the Department of Energy’s Oak Ridge National Laboratory to improve energy conversion methods for cleaner, more efficient oil and gas, chemical and