Filter News

Area of Research

- (-) Clean Energy (52)

- (-) Fusion and Fission (4)

- (-) Isotopes (3)

- Advanced Manufacturing (10)

- Biology and Environment (3)

- Computer Science (1)

- Fusion Energy (9)

- Materials (24)

- Materials for Computing (5)

- National Security (5)

- Neutron Science (6)

- Nuclear Science and Technology (30)

- Nuclear Systems Modeling, Simulation and Validation (2)

- Quantum information Science (2)

- Supercomputing (11)

- Transportation Systems (1)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (29)

- (-) Advanced Reactors (4)

- (-) Cybersecurity (2)

- (-) Isotopes (4)

- (-) Nuclear Energy (8)

- (-) Transportation (23)

- Artificial Intelligence (5)

- Big Data (2)

- Bioenergy (16)

- Biology (1)

- Biomedical (4)

- Biotechnology (2)

- Chemical Sciences (2)

- Clean Water (5)

- Climate Change (6)

- Composites (3)

- Computer Science (16)

- Coronavirus (7)

- Decarbonization (1)

- Energy Storage (20)

- Environment (29)

- Exascale Computing (1)

- Fusion (3)

- Grid (8)

- High-Performance Computing (1)

- Machine Learning (5)

- Materials (2)

- Materials Science (13)

- Mathematics (1)

- Mercury (1)

- Microscopy (4)

- Molten Salt (1)

- Nanotechnology (6)

- Neutron Science (6)

- Physics (1)

- Polymers (4)

- Quantum Science (2)

- Security (1)

- Space Exploration (1)

- Summit (2)

- Sustainable Energy (28)

- Transformational Challenge Reactor (2)

Media Contacts

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) in late February demonstrated a 20-kilowatt bi-directional wireless charging system installed on a UPS medium-duty, plug-in hybrid electric delivery truck.

Brian Post, a researcher in large-scale additive manufacturing at ORNL, has been selected as a recipient of the 2020 Outstanding Young Manufacturing Engineer Award by SME.

Hydropower developers must consider many factors when it comes time to license a new project or renew an existing one: How can environmental impacts be mitigated, including to fish populations?

Each year, approximately 6 billion gallons of fuel are wasted as vehicles wait at stop lights or sit in dense traffic with engines idling, according to US Department of Energy estimates.

Peter Wang is focused on robotics and automation at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, working on high-profile projects such as the MedUSA, a large-scale hybrid additive manufacturing machine.

A technology developed at the ORNL and scaled up by Vertimass LLC to convert ethanol into fuels suitable for aviation, shipping and other heavy-duty applications can be price-competitive with conventional fuels

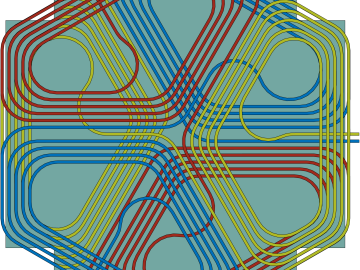

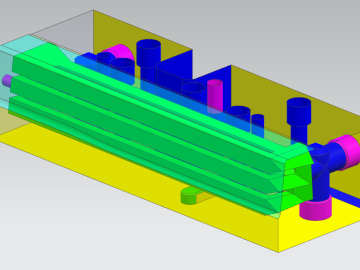

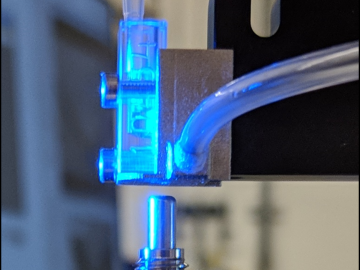

ORNL researchers created and tested new wireless charging designs that may double the power density, resulting in a lighter weight system compared with existing technologies.

Researchers demonstrated that an additively manufactured hot stamping die can withstand up to 25,000 usage cycles, proving that this technique is a viable solution for production.

Researchers at the Department of Energy’s Oak Ridge National Laboratory have received five 2019 R&D 100 Awards, increasing the lab’s total to 221 since the award’s inception in 1963.