Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (39)

- (-) Nanotechnology (19)

- Advanced Reactors (17)

- Artificial Intelligence (30)

- Big Data (19)

- Bioenergy (22)

- Biology (16)

- Biomedical (26)

- Biotechnology (7)

- Buildings (14)

- Chemical Sciences (17)

- Clean Water (5)

- Climate Change (29)

- Composites (5)

- Computer Science (57)

- Coronavirus (23)

- Critical Materials (5)

- Cybersecurity (4)

- Decarbonization (21)

- Education (1)

- Emergency (1)

- Energy Storage (29)

- Environment (47)

- Exascale Computing (8)

- Fossil Energy (2)

- Frontier (7)

- Fusion (18)

- Grid (13)

- High-Performance Computing (16)

- Isotopes (19)

- ITER (1)

- Machine Learning (16)

- Materials (15)

- Materials Science (50)

- Mathematics (4)

- Mercury (1)

- Microelectronics (1)

- Microscopy (10)

- Molten Salt (2)

- National Security (16)

- Net Zero (5)

- Neutron Science (40)

- Nuclear Energy (39)

- Partnerships (11)

- Physics (17)

- Polymers (12)

- Quantum Computing (10)

- Quantum Science (26)

- Security (5)

- Simulation (12)

- Space Exploration (5)

- Statistics (2)

- Summit (21)

- Sustainable Energy (40)

- Transformational Challenge Reactor (5)

- Transportation (27)

Media Contacts

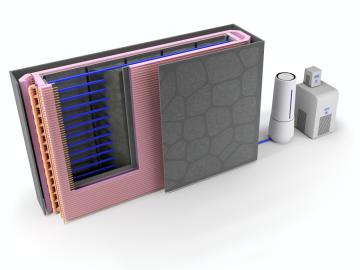

Oak Ridge National Laboratory researchers used additive manufacturing to build a first-of-its kind smart wall called EMPOWER.

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

Oak Ridge National Laboratory researchers have designed and additively manufactured a first-of-its-kind aluminum device that enhances the capture of carbon dioxide emitted from fossil fuel plants and other industrial processes.

The Society of Manufacturing Engineers, known as SME, has named William Peter, director of Oak Ridge National Laboratory’s Manufacturing Demonstration Facility in the Energy and Environmental Sciences Directorate, among its 2020 College of SME Fellows.

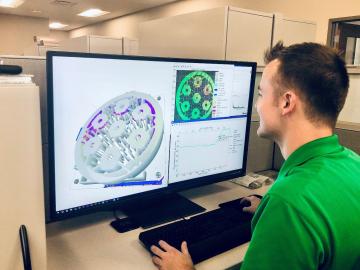

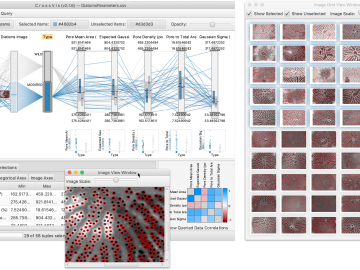

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

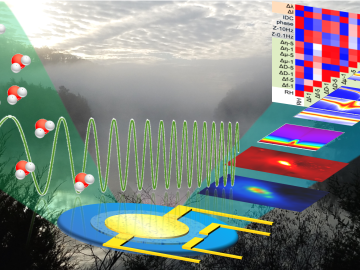

An all-in-one experimental platform developed at Oak Ridge National Laboratory’s Center for Nanophase Materials Sciences accelerates research on promising materials for future technologies.

ORNL has licensed two additive manufacturing-related technologies that aim to streamline and ramp up production processes to Knoxville-based Magnum Venus Products, Inc., a global manufacturer of fluid movement and product solutions for industrial applications in composites and adhesives.

From materials science and earth system modeling to quantum information science and cybersecurity, experts in many fields run simulations and conduct experiments to collect the abundance of data necessary for scientific progress.

Five researchers at the Department of Energy’s Oak Ridge National Laboratory have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

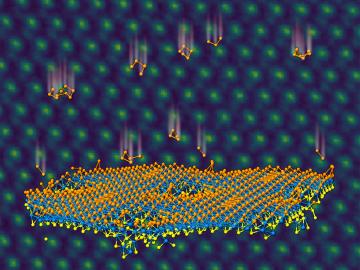

An ORNL team used a simple process to implant atoms precisely into the top layers of ultra-thin crystals, yielding two-sided structures with different chemical compositions.