Filter News

Area of Research

- Advanced Manufacturing (4)

- Biology and Environment (3)

- Clean Energy (24)

- Computer Science (1)

- Fusion and Fission (2)

- Fusion Energy (3)

- Materials (31)

- Materials for Computing (3)

- National Security (3)

- Neutron Science (11)

- Nuclear Science and Technology (9)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Supercomputing (10)

News Topics

- (-) 3-D Printing/Advanced Manufacturing (28)

- (-) Advanced Reactors (14)

- (-) Materials Science (37)

- Artificial Intelligence (8)

- Big Data (11)

- Bioenergy (12)

- Biology (5)

- Biomedical (21)

- Biotechnology (2)

- Buildings (1)

- Chemical Sciences (5)

- Clean Water (2)

- Climate Change (10)

- Composites (1)

- Computer Science (39)

- Coronavirus (23)

- Critical Materials (2)

- Cybersecurity (4)

- Decarbonization (1)

- Energy Storage (21)

- Environment (29)

- Exascale Computing (3)

- Frontier (1)

- Fusion (13)

- Grid (7)

- High-Performance Computing (3)

- Isotopes (8)

- Machine Learning (8)

- Materials (2)

- Mathematics (2)

- Mercury (1)

- Microscopy (8)

- Molten Salt (2)

- Nanotechnology (17)

- National Security (2)

- Neutron Science (30)

- Nuclear Energy (31)

- Physics (13)

- Polymers (7)

- Quantum Science (14)

- Security (3)

- Space Exploration (2)

- Summit (17)

- Sustainable Energy (24)

- Transformational Challenge Reactor (5)

- Transportation (15)

Media Contacts

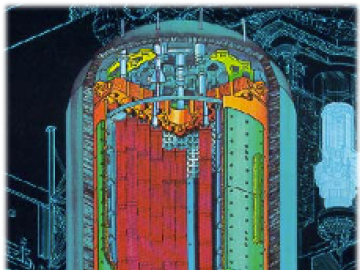

Researchers at the Department of Energy’s Oak Ridge National Laboratory are refining their design of a 3D-printed nuclear reactor core, scaling up the additive manufacturing process necessary to build it, and developing methods

In the 1960s, Oak Ridge National Laboratory's four-year Molten Salt Reactor Experiment tested the viability of liquid fuel reactors for commercial power generation. Results from that historic experiment recently became the basis for the first-ever molten salt reactor benchmark.

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

Brian Post, a researcher in large-scale additive manufacturing at ORNL, has been selected as a recipient of the 2020 Outstanding Young Manufacturing Engineer Award by SME.

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.

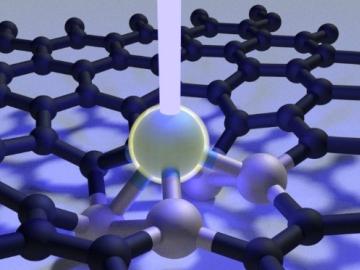

Scientists at Oak Ridge National Laboratory used a focused beam of electrons to stitch platinum-silicon molecules into graphene, marking the first deliberate insertion of artificial molecules into a graphene host matrix.

A software package, 10 years in the making, that can predict the behavior of nuclear reactors’ cores with stunning accuracy has been licensed commercially for the first time.

Hydropower developers must consider many factors when it comes time to license a new project or renew an existing one: How can environmental impacts be mitigated, including to fish populations?

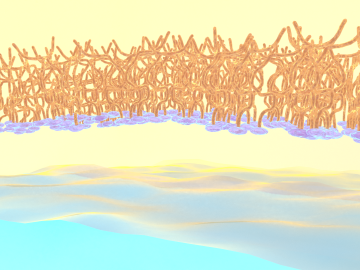

OAK RIDGE, Tenn., Feb. 27, 2020 — Researchers at Oak Ridge National Laboratory and the University of Tennessee achieved a rare look at the inner workings of polymer self-assembly at an oil-water interface to advance materials for neuromorphic computing and bio-inspired technologies.

We have a data problem. Humanity is now generating more data than it can handle; more sensors, smartphones, and devices of all types are coming online every day and contributing to the ever-growing global dataset.