Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (28)

- (-) Quantum Science (14)

- Advanced Reactors (14)

- Artificial Intelligence (8)

- Big Data (11)

- Bioenergy (12)

- Biology (5)

- Biomedical (21)

- Biotechnology (2)

- Buildings (1)

- Chemical Sciences (5)

- Clean Water (2)

- Climate Change (10)

- Composites (1)

- Computer Science (39)

- Coronavirus (23)

- Critical Materials (2)

- Cybersecurity (4)

- Decarbonization (1)

- Energy Storage (21)

- Environment (29)

- Exascale Computing (3)

- Frontier (1)

- Fusion (13)

- Grid (7)

- High-Performance Computing (3)

- Isotopes (8)

- Machine Learning (8)

- Materials (2)

- Materials Science (37)

- Mathematics (2)

- Mercury (1)

- Microscopy (8)

- Molten Salt (2)

- Nanotechnology (17)

- National Security (2)

- Neutron Science (30)

- Nuclear Energy (31)

- Physics (13)

- Polymers (7)

- Security (3)

- Space Exploration (2)

- Summit (17)

- Sustainable Energy (24)

- Transformational Challenge Reactor (5)

- Transportation (15)

Media Contacts

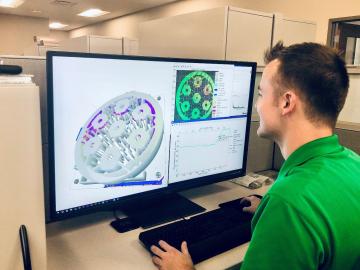

Oak Ridge National Laboratory researchers have developed artificial intelligence software for powder bed 3D printers that assesses the quality of parts in real time, without the need for expensive characterization equipment.

ORNL has licensed two additive manufacturing-related technologies that aim to streamline and ramp up production processes to Knoxville-based Magnum Venus Products, Inc., a global manufacturer of fluid movement and product solutions for industrial applications in composites and adhesives.

Five researchers at the Department of Energy’s Oak Ridge National Laboratory have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

Oak Ridge National Laboratory has licensed a novel method to 3D print components used in neutron instruments for scientific research to the ExOne Company, a leading maker of binder jet 3D printing technology.

ORNL welcomed six technology innovators to join the fourth cohort of Innovation Crossroads, the Southeast’s only entrepreneurial research and development program based at a U.S. Department of Energy national laboratory.

A team led by the Department of Energy’s Oak Ridge National Laboratory synthesized a tiny structure with high surface area and discovered how its unique architecture drives ions across interfaces to transport energy or information.

Matthew R. Ryder, a researcher at the Department of Energy’s Oak Ridge National Laboratory, has been named the 2020 Foresight Fellow in Molecular-Scale Engineering.

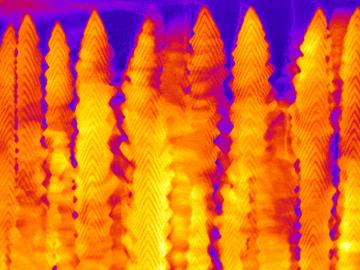

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

For the second year in a row, a team from the Department of Energy’s Oak Ridge and Los Alamos national laboratories led a demonstration hosted by EPB, a community-based utility and telecommunications company serving Chattanooga, Tennessee.

Researchers at the Department of Energy’s Oak Ridge National Laboratory are refining their design of a 3D-printed nuclear reactor core, scaling up the additive manufacturing process necessary to build it, and developing methods