Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (46)

- (-) Clean Water (13)

- Advanced Reactors (5)

- Artificial Intelligence (33)

- Big Data (15)

- Bioenergy (35)

- Biology (52)

- Biomedical (17)

- Biotechnology (11)

- Buildings (27)

- Chemical Sciences (31)

- Climate Change (42)

- Composites (12)

- Computer Science (53)

- Coronavirus (14)

- Critical Materials (10)

- Cybersecurity (14)

- Decarbonization (37)

- Education (3)

- Emergency (1)

- Energy Storage (43)

- Environment (82)

- Exascale Computing (17)

- Fossil Energy (2)

- Frontier (23)

- Fusion (17)

- Grid (27)

- High-Performance Computing (52)

- Hydropower (3)

- Irradiation (2)

- Isotopes (23)

- ITER (4)

- Machine Learning (16)

- Materials (91)

- Materials Science (38)

- Mathematics (3)

- Mercury (5)

- Microelectronics (2)

- Microscopy (17)

- Molten Salt (1)

- Nanotechnology (17)

- National Security (28)

- Net Zero (6)

- Neutron Science (50)

- Nuclear Energy (27)

- Partnerships (24)

- Physics (17)

- Polymers (9)

- Quantum Computing (17)

- Quantum Science (21)

- Renewable Energy (2)

- Security (6)

- Simulation (29)

- Software (1)

- Space Exploration (8)

- Statistics (1)

- Summit (18)

- Sustainable Energy (52)

- Transportation (39)

Media Contacts

Amy Elliott, a group leader for robotics and intelligent systems at Oak Ridge National Laboratory, has received the 2021 ASTM International Additive Manufacturing Young Professional Award for her early career research contributions

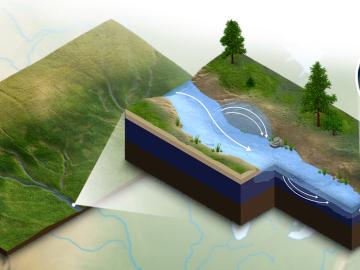

A new modeling capability developed at Oak Ridge National Laboratory incorporates important biogeochemical processes happening in river corridors for a clearer understanding of how water quality will be impacted by climate change, land use and

New data hosted through the Atmospheric Radiation Measurement Data Center at Oak Ridge National Laboratory will help improve models that predict climate change effects on the water supply in the Colorado River Basin.

Oak Ridge National Laboratory researchers have developed a novel process to manufacture extreme heat resistant carbon-carbon composites. The performance of these materials will be tested in a U.S. Navy rocket that NASA will launch this fall.

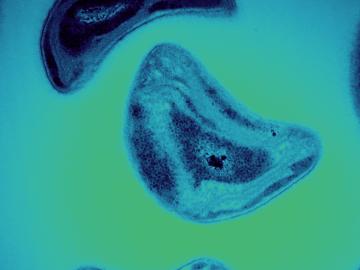

A team led by ORNL and the University of Michigan have discovered that certain bacteria can steal an essential compound from other microbes to break down methane and toxic methylmercury in the environment.

Anyone familiar with ORNL knows it’s a hub for world-class science. The nearly 33,000-acre space surrounding the lab is less known, but also unique.

Oak Ridge National Laboratory researchers demonstrated that cooling cost savings could be achieved with a 3D printed concrete smart wall following a three-month field test.

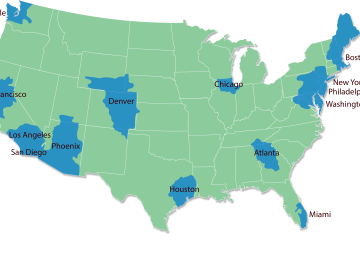

Oak Ridge National Laboratory worked with Colorado State University to simulate how a warming climate may affect U.S. urban hydrological systems.

Moving to landlocked Tennessee isn’t an obvious choice for most scientists with new doctorate degrees in coastal oceanography.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating