Filter News

Area of Research

News Topics

- (-) Energy Storage (10)

- (-) Space Exploration (4)

- 3-D Printing/Advanced Manufacturing (16)

- Advanced Reactors (2)

- Artificial Intelligence (5)

- Big Data (3)

- Bioenergy (12)

- Biology (18)

- Biomedical (6)

- Biotechnology (4)

- Buildings (6)

- Chemical Sciences (3)

- Clean Water (8)

- Climate Change (10)

- Composites (3)

- Computer Science (21)

- Coronavirus (5)

- Critical Materials (2)

- Cybersecurity (2)

- Decarbonization (4)

- Environment (34)

- Exascale Computing (2)

- Frontier (1)

- Fusion (3)

- Grid (6)

- High-Performance Computing (14)

- Isotopes (8)

- ITER (3)

- Materials (21)

- Materials Science (13)

- Mathematics (1)

- Mercury (3)

- Microscopy (6)

- Nanotechnology (5)

- National Security (4)

- Net Zero (1)

- Neutron Science (10)

- Nuclear Energy (4)

- Physics (2)

- Polymers (2)

- Quantum Computing (2)

- Quantum Science (7)

- Security (2)

- Statistics (1)

- Summit (4)

- Sustainable Energy (27)

- Transportation (14)

Media Contacts

Burak Ozpineci started out at ORNL working on a novel project: introducing silicon carbide into power electronics for more efficient electric vehicles. Twenty years later, the car he drives contains those same components.

Energy Secretary Jennifer Granholm visited ORNL on Nov. 22 for a two-hour tour, meeting top scientists and engineers as they highlighted projects and world-leading capabilities that address some of the country’s most complex research and technical challenges.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

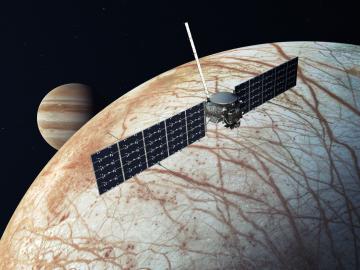

Researchers from NASA’s Jet Propulsion Laboratory and Oak Ridge National Laboratory successfully created amorphous ice, similar to ice in interstellar space and on icy worlds in our solar system. They documented that its disordered atomic behavior is unlike any ice on Earth.

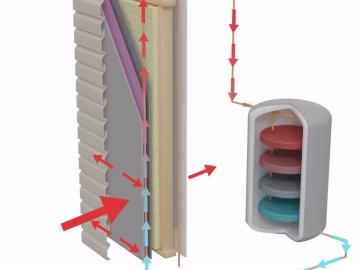

Researchers at Oak Ridge National Laboratory have developed a novel envelope system that diverts heat or coolness away from a building and stores it for future use.

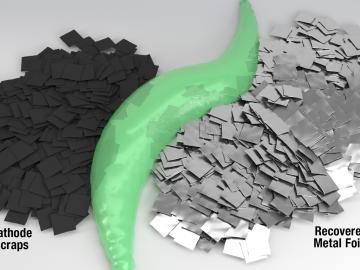

Scientists at Oak Ridge National Laboratory have developed a solvent that results in a more environmentally friendly process to recover valuable materials from used lithium-ion batteries, supports a stable domestic supply chain for new batteries

Consumer buy-in is key to the future of a decarbonized transportation sector in which electric vehicles largely replace today’s conventionally fueled cars and trucks.

Through a consortium of Department of Energy national laboratories, ORNL scientists are applying their expertise to provide solutions that enable the commercialization of emission-free hydrogen fuel cell technology for heavy-duty

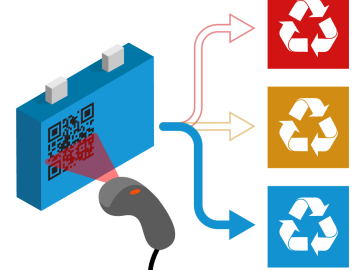

Scientists at Oak Ridge National Laboratory have devised a method to identify the unique chemical makeup of every lithium-ion battery around the world, information that could accelerate recycling, recover critical materials and resolve a growing waste stream.

Scientists at Oak Ridge National Laboratory successfully demonstrated a technique to heal dendrites that formed in a solid electrolyte, resolving an issue that can hamper the performance of high energy-density, solid-state batteries.