Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (26)

- (-) Materials (32)

- Advanced Reactors (2)

- Artificial Intelligence (7)

- Big Data (5)

- Bioenergy (13)

- Biology (23)

- Biomedical (10)

- Biotechnology (5)

- Buildings (13)

- Chemical Sciences (7)

- Clean Water (8)

- Climate Change (11)

- Composites (6)

- Computer Science (30)

- Coronavirus (10)

- Critical Materials (4)

- Cybersecurity (5)

- Decarbonization (7)

- Energy Storage (22)

- Environment (39)

- Exascale Computing (2)

- Frontier (4)

- Fusion (8)

- Grid (11)

- High-Performance Computing (19)

- Isotopes (12)

- ITER (4)

- Machine Learning (1)

- Materials Science (22)

- Mathematics (1)

- Mercury (3)

- Microscopy (10)

- Nanotechnology (10)

- National Security (7)

- Net Zero (1)

- Neutron Science (18)

- Nuclear Energy (6)

- Physics (3)

- Polymers (5)

- Quantum Computing (5)

- Quantum Science (12)

- Security (3)

- Space Exploration (4)

- Statistics (1)

- Summit (9)

- Sustainable Energy (35)

- Transportation (21)

Media Contacts

Oak Ridge National Laboratory researchers have additively manufactured a lightweight aluminum alloy and demonstrated its ability to resist creep or deformation at 300 degrees Celsius.

Research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received seven 2021 R&D 100 Awards, plus special recognition for a COVID-19-related project.

Matthew Ryder has been named an emerging investigator by the American Chemical Society journal Crystal Growth and Design. The ACS recognized him as “one of an emerging generation of research group leaders for his work on porous materials design.”

Oak Ridge National Laboratory researchers have developed a novel process to manufacture extreme heat resistant carbon-carbon composites. The performance of these materials will be tested in a U.S. Navy rocket that NASA will launch this fall.

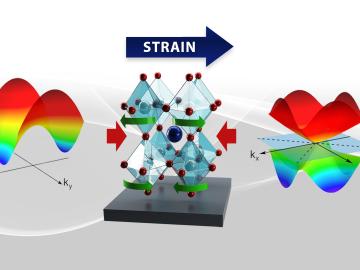

A team led by the ORNL has found a rare quantum material in which electrons move in coordinated ways, essentially “dancing.”

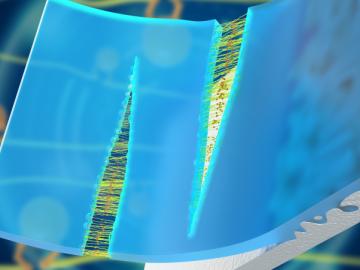

A multidisciplinary team of scientists at ORNL has applied a laser-interference structuring, or LIS, technique that makes significant strides toward eliminating the need for hazardous chemicals in corrosion protection for vehicles.

Oak Ridge National Laboratory researchers demonstrated that cooling cost savings could be achieved with a 3D printed concrete smart wall following a three-month field test.

Researchers at ORNL have developed a robotic disassembly system for spent electric vehicle battery packs to safely and efficiently recycle and reuse critical materials while reducing toxic waste.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.