Filter News

Area of Research

News Type

News Topics

- (-) Advanced Reactors (3)

- (-) Biomedical (4)

- (-) Energy Storage (17)

- (-) Frontier (9)

- (-) Isotopes (3)

- (-) Materials Science (12)

- 3-D Printing/Advanced Manufacturing (7)

- Artificial Intelligence (9)

- Big Data (5)

- Bioenergy (15)

- Biology (23)

- Biotechnology (3)

- Buildings (7)

- Chemical Sciences (13)

- Clean Water (2)

- Climate Change (23)

- Composites (1)

- Computer Science (15)

- Coronavirus (5)

- Critical Materials (1)

- Cybersecurity (7)

- Decarbonization (19)

- Element Discovery (1)

- Environment (30)

- Exascale Computing (6)

- Fossil Energy (1)

- Fusion (7)

- Grid (8)

- High-Performance Computing (10)

- Hydropower (3)

- ITER (2)

- Machine Learning (7)

- Materials (24)

- Mercury (1)

- Microscopy (10)

- Nanotechnology (7)

- National Security (14)

- Net Zero (2)

- Neutron Science (10)

- Nuclear Energy (10)

- Partnerships (7)

- Physics (9)

- Polymers (4)

- Quantum Computing (7)

- Quantum Science (7)

- Security (4)

- Simulation (3)

- Space Exploration (1)

- Summit (5)

- Sustainable Energy (18)

- Transformational Challenge Reactor (2)

- Transportation (8)

Media Contacts

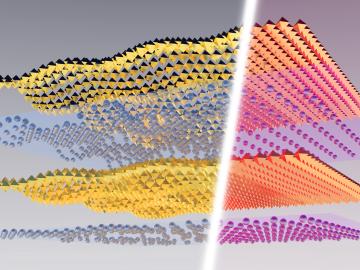

A study led by researchers at ORNL could help make materials design as customizable as point-and-click.

A study by researchers at the ORNL takes a fresh look at what could become the first step toward a new generation of solar batteries.

ORNL and the Tennessee Valley Authority, or TVA, are joining forces to advance decarbonization technologies from discovery through deployment through a new memorandum of understanding, or MOU.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

Muralidharan was recognized for “a highly prolific spirit of innovation in creating or facilitating outstanding inventions that have made a tangible impact on the quality of life, economic development and welfare of society.”

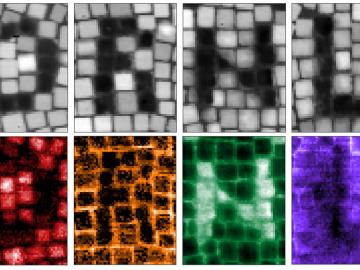

Drilling with the beam of an electron microscope, scientists at ORNL precisely machined tiny electrically conductive cubes that can interact with light and organized them in patterned structures that confine and relay light’s electromagnetic signal.

More than 50 current employees and recent retirees from ORNL received Department of Energy Secretary’s Honor Awards from Secretary Jennifer Granholm in January as part of project teams spanning the national laboratory system. The annual awards recognized 21 teams and three individuals for service and contributions to DOE’s mission and to the benefit of the nation.

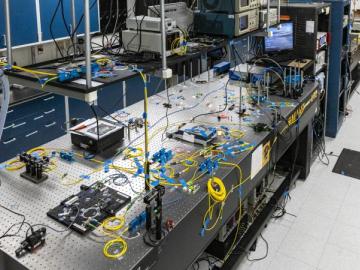

A rapidly emerging consensus in the scientific community predicts the future will be defined by humanity’s ability to exploit the laws of quantum mechanics.

To explore the inner workings of severe acute respiratory syndrome coronavirus 2, or SARS-CoV-2, researchers from ORNL developed a novel technique.

A novel method to 3D print components for nuclear reactors, developed by the Department of Energy’s Oak Ridge National Laboratory, has been licensed by Ultra Safe Nuclear Corporation.