Filter News

Area of Research

News Topics

- (-) Buildings (10)

- (-) Critical Materials (3)

- 3-D Printing/Advanced Manufacturing (6)

- Advanced Reactors (1)

- Artificial Intelligence (3)

- Big Data (3)

- Bioenergy (10)

- Biology (11)

- Biomedical (3)

- Chemical Sciences (4)

- Clean Water (4)

- Climate Change (9)

- Composites (3)

- Computer Science (5)

- Coronavirus (4)

- Cybersecurity (2)

- Decarbonization (8)

- Energy Storage (7)

- Environment (13)

- Exascale Computing (1)

- Grid (5)

- High-Performance Computing (5)

- Hydropower (5)

- Irradiation (1)

- Isotopes (1)

- Machine Learning (3)

- Materials (14)

- Materials Science (4)

- Mercury (1)

- Microscopy (7)

- Nanotechnology (2)

- National Security (8)

- Net Zero (2)

- Neutron Science (2)

- Nuclear Energy (2)

- Partnerships (1)

- Physics (2)

- Polymers (2)

- Quantum Science (2)

- Simulation (3)

- Space Exploration (3)

- Summit (1)

- Sustainable Energy (11)

- Transportation (4)

Media Contacts

Researchers at ORNL have developed a tool that provides accurate measurements and positioning directions to those installing energy-efficient panels over existing building exteriors. This method will decrease installation time and cost by more than 25%.

Materials scientist Denise Antunes da Silva researches ways to reduce concrete’s embodied carbon in the Sustainable Building Materials Laboratory at ORNL, a research space dedicated to studying environmentally friendly building materials. Credit: ORNL, U.S. Dept. of Energy

Researchers at ORNL have developed an online tool that offers industrial plants an easier way to track and download information about their energy footprint and carbon emissions.

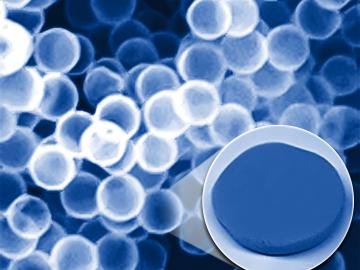

ORNL researchers demonstrated a process for producing a moisture-stable, lightweight thermal insulation material using hollow silica particles, or HSPs.

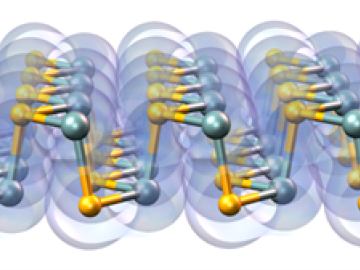

A multi-lab research team led by ORNL's Paul Kent is developing a computer application called QMCPACK to enable precise and reliable predictions of the fundamental properties of materials critical in energy research.

Oak Ridge National Laboratory researchers demonstrated that microchannel heat exchangers in heating, ventilation and air conditioning units can keep refrigerants evenly and continually distributed by inserting a device called a piezoelectric-driven

Researchers at Oak Ridge National Laboratory and Momentum Technologies have piloted an industrial-scale process for recycling valuable materials in the millions of tons of e-waste generated annually in the United States.

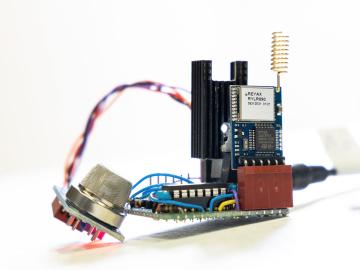

Oak Ridge National Laboratory researchers demonstrated that an electrochemical sensor paired with a transmitter not only detects propane leaks within seconds, but it can also send a signal to alert emergency services.

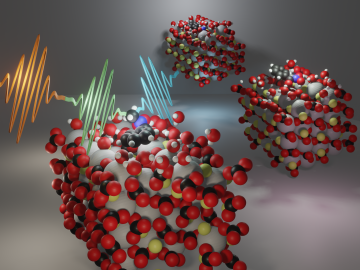

Researchers at Oak Ridge National Laboratory are using state-of-the-art methods to shed light on chemical separations needed to recover rare-earth elements and secure critical materials for clean energy technologies.

A prototype cooking appliance developed by Oak Ridge National Laboratory uses a 50% blend of hydrogen and natural gas, offering an alternative to safely reduce emissions that contribute to the nation’s carbon footprint.