Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (12)

- (-) Advanced Reactors (4)

- (-) Artificial Intelligence (14)

- (-) Fusion (7)

- Big Data (9)

- Bioenergy (19)

- Biology (28)

- Biomedical (6)

- Biotechnology (3)

- Buildings (16)

- Chemical Sciences (15)

- Clean Water (5)

- Climate Change (26)

- Composites (3)

- Computer Science (20)

- Coronavirus (9)

- Critical Materials (4)

- Cybersecurity (7)

- Decarbonization (21)

- Element Discovery (1)

- Energy Storage (25)

- Environment (36)

- Exascale Computing (8)

- Fossil Energy (1)

- Frontier (10)

- Grid (13)

- High-Performance Computing (16)

- Hydropower (8)

- Irradiation (1)

- Isotopes (4)

- ITER (2)

- Machine Learning (10)

- Materials (37)

- Materials Science (16)

- Mercury (1)

- Microscopy (13)

- Nanotechnology (9)

- National Security (17)

- Net Zero (2)

- Neutron Science (12)

- Nuclear Energy (10)

- Partnerships (8)

- Physics (10)

- Polymers (5)

- Quantum Computing (7)

- Quantum Science (9)

- Security (4)

- Simulation (6)

- Space Exploration (4)

- Summit (7)

- Sustainable Energy (25)

- Transformational Challenge Reactor (2)

- Transportation (10)

Media Contacts

Three researchers at ORNL have been named ORNL Corporate Fellows in recognition of significant career accomplishments and continued leadership in their scientific fields.

The presence of minerals called ash in plants makes little difference to the fitness of new naturally derived compound materials designed for additive manufacturing, an Oak Ridge National Laboratory-led team found.

While studying how bio-inspired materials might inform the design of next-generation computers, scientists at ORNL achieved a first-of-its-kind result that could have big implications for both edge computing and human health.

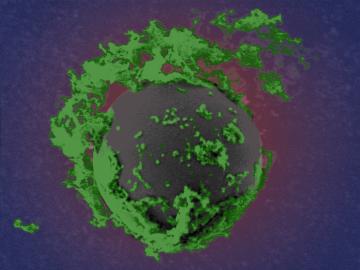

ORNL researchers discovered genetic mutations that underlie autism using a new approach that could lead to better diagnostics and drug therapies.

Oak Ridge National Laboratory scientists designed a recyclable polymer for carbon-fiber composites to enable circular manufacturing of parts that boost energy efficiency in automotive, wind power and aerospace applications.

Several significant science and energy projects led by the ORNL will receive a total of $497 million in funding from the Inflation Reduction Act.

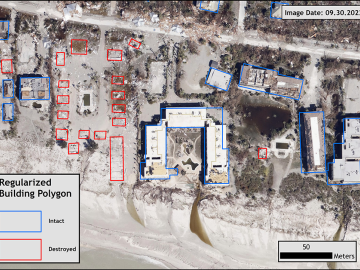

Over the past seven years, researchers in ORNL’s Geospatial Science and Human Security Division have mapped and characterized all structures within the United States and its territories to aid FEMA in its response to disasters. This dataset provides a consistent, nationwide accounting of the buildings where people reside and work.

A new deep-learning framework developed at ORNL is speeding up the process of inspecting additively manufactured metal parts using X-ray computed tomography, or CT, while increasing the accuracy of the results. The reduced costs for time, labor, maintenance and energy are expected to accelerate expansion of additive manufacturing, or 3D printing.

Researchers at ORNL have developed an online tool that offers industrial plants an easier way to track and download information about their energy footprint and carbon emissions.

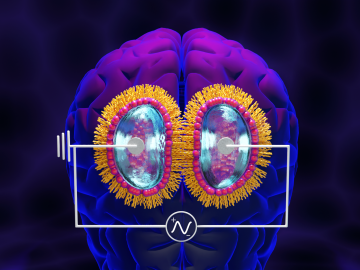

Researchers in the geothermal energy industry are joining forces with fusion experts at ORNL to repurpose gyrotron technology, a tool used in fusion. Gyrotrons produce high-powered microwaves to heat up fusion plasmas.