Filter News

Area of Research

News Topics

- (-) Artificial Intelligence (14)

- (-) Critical Materials (4)

- (-) Fusion (7)

- 3-D Printing/Advanced Manufacturing (12)

- Advanced Reactors (4)

- Big Data (9)

- Bioenergy (19)

- Biology (28)

- Biomedical (6)

- Biotechnology (3)

- Buildings (16)

- Chemical Sciences (15)

- Clean Water (5)

- Climate Change (26)

- Composites (3)

- Computer Science (20)

- Coronavirus (9)

- Cybersecurity (7)

- Decarbonization (21)

- Element Discovery (1)

- Energy Storage (25)

- Environment (36)

- Exascale Computing (8)

- Fossil Energy (1)

- Frontier (10)

- Grid (13)

- High-Performance Computing (16)

- Hydropower (8)

- Irradiation (1)

- Isotopes (4)

- ITER (2)

- Machine Learning (10)

- Materials (37)

- Materials Science (16)

- Mercury (1)

- Microscopy (13)

- Nanotechnology (9)

- National Security (17)

- Net Zero (2)

- Neutron Science (12)

- Nuclear Energy (10)

- Partnerships (8)

- Physics (10)

- Polymers (5)

- Quantum Computing (7)

- Quantum Science (9)

- Security (4)

- Simulation (6)

- Space Exploration (4)

- Summit (7)

- Sustainable Energy (25)

- Transformational Challenge Reactor (2)

- Transportation (10)

Media Contacts

Researchers at Oak Ridge National Laboratory and Momentum Technologies have piloted an industrial-scale process for recycling valuable materials in the millions of tons of e-waste generated annually in the United States.

Practical fusion energy is not just a dream at ORNL. Experts in fusion and material science are working together to develop solutions that will make a fusion pilot plant — and ultimately carbon-free, abundant fusion electricity — possible.

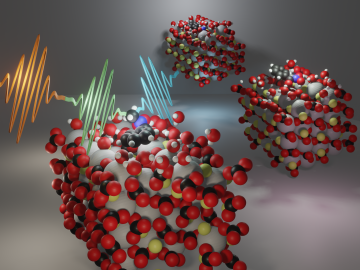

Researchers at Oak Ridge National Laboratory are using state-of-the-art methods to shed light on chemical separations needed to recover rare-earth elements and secure critical materials for clean energy technologies.

Oak Ridge National Laboratory researchers developed an invertible neural network, a type of artificial intelligence that mimics the human brain, to improve accuracy in climate-change models and predictions.

The Frontier supercomputer at the Department of Energy’s Oak Ridge National Laboratory earned the top ranking today as the world’s fastest on the 59th TOP500 list, with 1.1 exaflops of performance. The system is the first to achieve an unprecedented level of computing performance known as exascale, a threshold of a quintillion calculations per second.

To achieve practical energy from fusion, extreme heat from the fusion system “blanket” component must be extracted safely and efficiently. ORNL fusion experts are exploring how tiny 3D-printed obstacles placed inside the narrow pipes of a custom-made cooling system could be a solution for removing heat from the blanket.

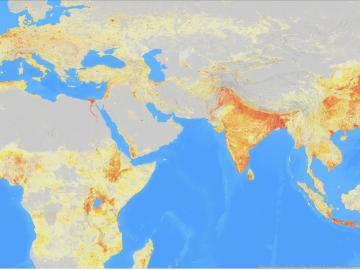

It’s a simple premise: To truly improve the health, safety, and security of human beings, you must first understand where those individuals are.

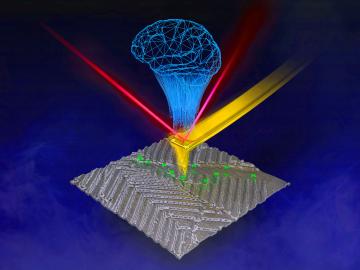

Researchers at ORNL are teaching microscopes to drive discoveries with an intuitive algorithm, developed at the lab’s Center for Nanophase Materials Sciences, that could guide breakthroughs in new materials for energy technologies, sensing and computing.

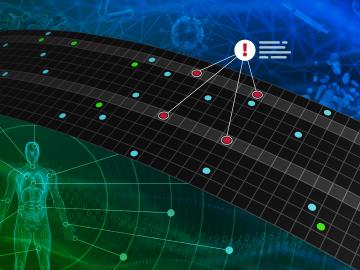

A team of researchers has developed a novel, machine learning–based technique to explore and identify relationships among medical concepts using electronic health record data across multiple healthcare providers.

A study led by researchers at ORNL could help make materials design as customizable as point-and-click.