Filter News

Area of Research

News Topics

- (-) Neutron Science (32)

- (-) Partnerships (24)

- 3-D Printing/Advanced Manufacturing (20)

- Advanced Reactors (3)

- Artificial Intelligence (26)

- Big Data (10)

- Bioenergy (22)

- Biology (29)

- Biomedical (7)

- Biotechnology (6)

- Buildings (14)

- Chemical Sciences (24)

- Clean Water (5)

- Climate Change (31)

- Composites (6)

- Computer Science (23)

- Coronavirus (4)

- Critical Materials (6)

- Cybersecurity (9)

- Decarbonization (30)

- Education (3)

- Emergency (1)

- Energy Storage (21)

- Environment (43)

- Exascale Computing (15)

- Fossil Energy (2)

- Frontier (19)

- Fusion (9)

- Grid (16)

- High-Performance Computing (33)

- Hydropower (3)

- Irradiation (2)

- Isotopes (11)

- Machine Learning (15)

- Materials (59)

- Materials Science (16)

- Mathematics (2)

- Mercury (2)

- Microelectronics (2)

- Microscopy (7)

- Molten Salt (1)

- Nanotechnology (7)

- National Security (21)

- Net Zero (5)

- Nuclear Energy (21)

- Physics (14)

- Polymers (4)

- Quantum Computing (12)

- Quantum Science (9)

- Renewable Energy (2)

- Security (3)

- Simulation (29)

- Software (1)

- Space Exploration (4)

- Summit (9)

- Sustainable Energy (17)

- Transportation (18)

Media Contacts

The Spallation Neutron Source — already the world’s most powerful accelerator-based neutron source — will be on a planned hiatus through June 2024 as crews work to upgrade the facility. Much of the work — part of the facility’s Proton Power Upgrade project — will involve building a connector between the accelerator and the planned Second Target Station.

ORNL has launched a new entrepreneurial start-up program, Safari, as an addition to DOE's Office of Technology Transitions Practices to Accelerate the Commercialization of Technologies program. Safari seeks to connect post-exit entrepreneurs with commercially relevant technologies developed by world-leading scientific experts, which could provide the basis for a new business.

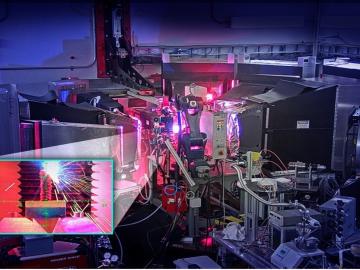

Neutron experiments can take days to complete, requiring researchers to work long shifts to monitor progress and make necessary adjustments. But thanks to advances in artificial intelligence and machine learning, experiments can now be done remotely and in half the time.

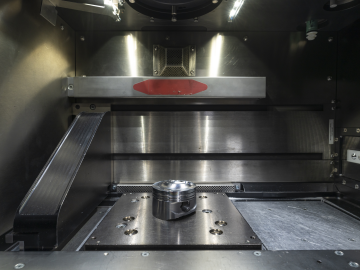

A licensing agreement between the Department of Energy’s Oak Ridge National Laboratory and research partner ZEISS will enable industrial X-ray computed tomography, or CT, to perform rapid evaluations of 3D-printed components using ORNL’s machine

Technologies developed by researchers at ORNL have received six 2023 R&D 100 Awards.

A group at the Department of Energy's Oak Ridge National Laboratory made a difference for local youth through hands-on projects that connected neutron science and engineering intuitively.

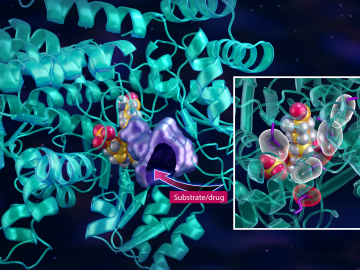

After a highly lauded research campaign that successfully redesigned a hepatitis C drug into one of the leading drug treatments for COVID-19, scientists at ORNL are now turning their drug design approach toward cancer.

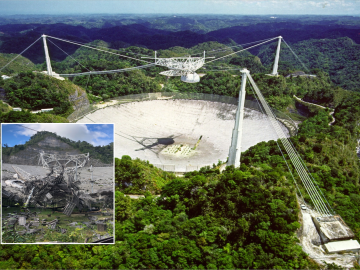

For more than half a century, the 1,000-foot-diameter spherical reflector dish at the Arecibo Observatory in Puerto Rico was the largest radio telescope in the world. Completed in 1963, the dish was built in a natural sinkhole, with the telescope’s feed antenna suspended 500 feet above the dish on a 1.8-million-pound steel platform. Three concrete towers and more than 4 miles of steel cables supported the platform.

Entrepreneur-fellows in Innovation Crossroads will complete the Spark Cleantech Accelerator, a 12-week program offered by the Spark Innovation Center at the UT Research Park.

Dean Pierce of ORNL and a research team led by ORNL’s Alex Plotkowski were honored by DOE’s Vehicle Technologies Office for development of novel high-performance alloys that can withstand extreme environments.