Filter News

Area of Research

News Type

News Topics

- (-) Advanced Reactors (13)

- (-) Renewable Energy (1)

- 3-D Printing/Advanced Manufacturing (51)

- Artificial Intelligence (51)

- Big Data (24)

- Bioenergy (53)

- Biology (62)

- Biomedical (32)

- Biotechnology (10)

- Buildings (22)

- Chemical Sciences (32)

- Clean Water (14)

- Climate Change (52)

- Composites (9)

- Computer Science (95)

- Coronavirus (21)

- Critical Materials (2)

- Cybersecurity (20)

- Decarbonization (45)

- Education (1)

- Emergency (2)

- Energy Storage (43)

- Environment (113)

- Exascale Computing (26)

- Fossil Energy (4)

- Frontier (26)

- Fusion (36)

- Grid (25)

- High-Performance Computing (53)

- Hydropower (5)

- Irradiation (1)

- Isotopes (31)

- ITER (3)

- Machine Learning (23)

- Materials (70)

- Materials Science (61)

- Mathematics (5)

- Mercury (7)

- Microelectronics (2)

- Microscopy (28)

- Molten Salt (2)

- Nanotechnology (28)

- National Security (40)

- Net Zero (8)

- Neutron Science (58)

- Nuclear Energy (65)

- Partnerships (17)

- Physics (32)

- Polymers (12)

- Quantum Computing (19)

- Quantum Science (31)

- Security (13)

- Simulation (33)

- Software (1)

- Space Exploration (13)

- Summit (32)

- Sustainable Energy (48)

- Transformational Challenge Reactor (4)

- Transportation (35)

Media Contacts

Researchers tackling national security challenges at ORNL are upholding an 80-year legacy of leadership in all things nuclear. Today, they’re developing the next generation of technologies that will help reduce global nuclear risk and enable safe, secure, peaceful use of nuclear materials, worldwide.

Scientists at Oak Ridge National Laboratory and six other Department of Energy national laboratories have developed a United States-based perspective for achieving net-zero carbon emissions.

Anne Campbell, a researcher at ORNL, recently won the Young Leaders Professional Development Award from the Minerals, Metals & Materials Society, or TMS, and has been chosen as the first recipient of the Young Leaders International Scholar Program award from TMS and the Korean Institute of Metals and Materials, or KIM.

Scientist Xiaohan Yang’s research at the Department of Energy’s Oak Ridge National Laboratory focuses on transforming plants to make them better sources of renewable energy and carbon storage.

A partnership of ORNL, the Tennessee Department of Economic and Community Development, the Community Reuse Organization of East Tennessee and TVA that aims to attract nuclear energy-related firms to Oak Ridge has been recognized with a state and local economic development award from the Federal Laboratory Consortium.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

Four first-of-a-kind 3D-printed fuel assembly brackets, produced at the Department of Energy’s Manufacturing Demonstration Facility at Oak Ridge National Laboratory, have been installed and are now under routine operating

David Kropaczek, director of the Consortium for Advanced Simulation of Light Water Reactors, or CASL, at the Department of Energy’s Oak Ridge National Laboratory, has been named a fellow of the American Nuclear Society.

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.

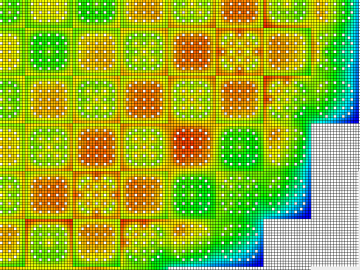

As CASL ends and transitions to VERA Users Group, ORNL looks at the history of the program and its impact on the nuclear industry.