Filter News

Area of Research

- Advanced Manufacturing (5)

- Biology and Environment (21)

- Clean Energy (43)

- Computational Biology (1)

- Computer Science (1)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (1)

- Fusion and Fission (7)

- Isotopes (3)

- Materials (37)

- Materials for Computing (7)

- National Security (8)

- Neutron Science (12)

- Nuclear Science and Technology (3)

- Quantum information Science (2)

- Supercomputing (44)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (59)

- (-) Artificial Intelligence (56)

- (-) Exascale Computing (29)

- (-) Microscopy (28)

- (-) Nanotechnology (28)

- (-) Polymers (13)

- (-) Software (1)

- (-) Space Exploration (13)

- Advanced Reactors (13)

- Big Data (31)

- Bioenergy (57)

- Biology (66)

- Biomedical (33)

- Biotechnology (12)

- Buildings (25)

- Chemical Sciences (37)

- Clean Water (14)

- Climate Change (57)

- Composites (12)

- Computer Science (103)

- Coronavirus (21)

- Critical Materials (5)

- Cybersecurity (20)

- Decarbonization (49)

- Education (1)

- Emergency (2)

- Energy Storage (44)

- Environment (118)

- Fossil Energy (4)

- Frontier (28)

- Fusion (39)

- Grid (28)

- High-Performance Computing (56)

- Hydropower (5)

- Irradiation (1)

- Isotopes (35)

- ITER (3)

- Machine Learning (24)

- Materials (74)

- Materials Science (66)

- Mathematics (7)

- Mercury (7)

- Microelectronics (2)

- Molten Salt (2)

- National Security (46)

- Net Zero (9)

- Neutron Science (59)

- Nuclear Energy (68)

- Partnerships (24)

- Physics (36)

- Quantum Computing (23)

- Quantum Science (34)

- Renewable Energy (1)

- Security (14)

- Simulation (36)

- Statistics (1)

- Summit (33)

- Sustainable Energy (55)

- Transformational Challenge Reactor (4)

- Transportation (37)

Media Contacts

Tony Schmitz, joint faculty researcher in machining and machine tools at Oak Ridge National Laboratory, and mechanical, aerospace and biomedical engineering professor at the University of Tennessee, Knoxville, has been elected to the College of Fellows of the American Society for Precision Engineering.

Four research teams from the Department of Energy’s Oak Ridge National Laboratory and their technologies have received 2020 R&D 100 Awards.

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

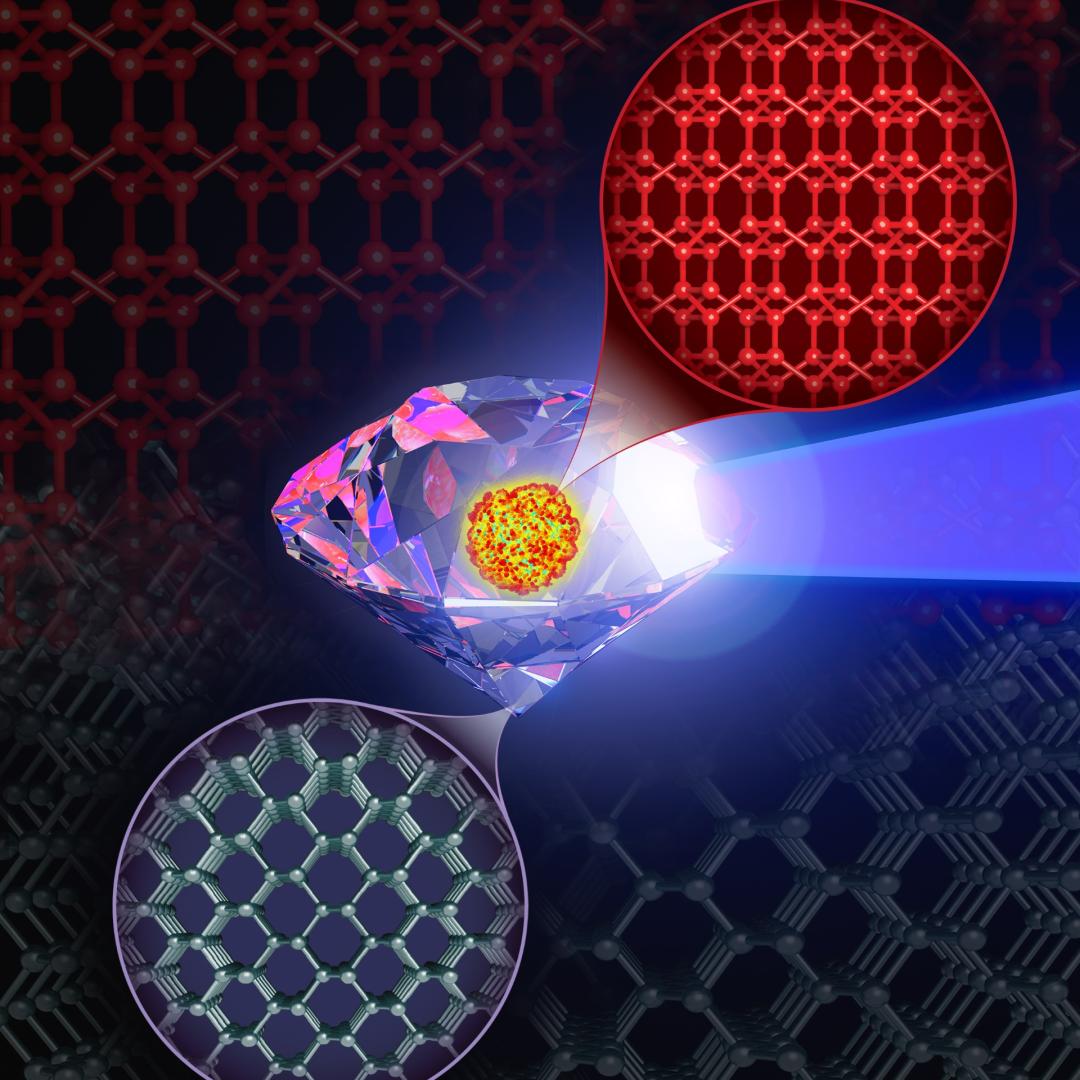

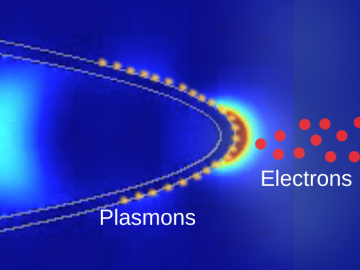

Scientists at ORNL and the University of Nebraska have developed an easier way to generate electrons for nanoscale imaging and sensing, providing a useful new tool for material science, bioimaging and fundamental quantum research.

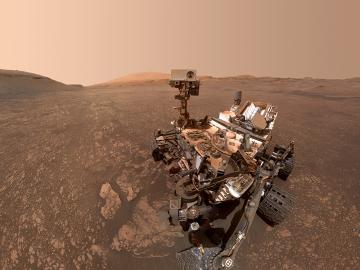

Radioactive isotopes power some of NASA’s best-known spacecraft. But predicting how radiation emitted from these isotopes might affect nearby materials is tricky

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

The Society of Manufacturing Engineers, known as SME, has named William Peter, director of Oak Ridge National Laboratory’s Manufacturing Demonstration Facility in the Energy and Environmental Sciences Directorate, among its 2020 College of SME Fellows.

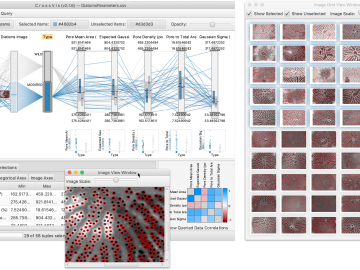

From materials science and earth system modeling to quantum information science and cybersecurity, experts in many fields run simulations and conduct experiments to collect the abundance of data necessary for scientific progress.

Matthew R. Ryder, a researcher at the Department of Energy’s Oak Ridge National Laboratory, has been named the 2020 Foresight Fellow in Molecular-Scale Engineering.

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.