Filter News

Area of Research

News Type

News Topics

- (-) Big Data (31)

- (-) Fossil Energy (4)

- 3-D Printing/Advanced Manufacturing (59)

- Advanced Reactors (13)

- Artificial Intelligence (56)

- Bioenergy (57)

- Biology (66)

- Biomedical (33)

- Biotechnology (12)

- Buildings (25)

- Chemical Sciences (38)

- Clean Water (14)

- Climate Change (58)

- Composites (12)

- Computer Science (103)

- Coronavirus (21)

- Critical Materials (6)

- Cybersecurity (20)

- Decarbonization (49)

- Education (1)

- Emergency (2)

- Energy Storage (45)

- Environment (119)

- Exascale Computing (29)

- Frontier (28)

- Fusion (39)

- Grid (28)

- High-Performance Computing (56)

- Hydropower (5)

- Irradiation (1)

- Isotopes (36)

- ITER (3)

- Machine Learning (24)

- Materials (75)

- Materials Science (67)

- Mathematics (7)

- Mercury (7)

- Microelectronics (3)

- Microscopy (28)

- Molten Salt (2)

- Nanotechnology (28)

- National Security (49)

- Net Zero (9)

- Neutron Science (61)

- Nuclear Energy (69)

- Partnerships (25)

- Physics (36)

- Polymers (13)

- Quantum Computing (23)

- Quantum Science (35)

- Renewable Energy (1)

- Security (14)

- Simulation (36)

- Software (1)

- Space Exploration (13)

- Statistics (1)

- Summit (33)

- Sustainable Energy (55)

- Transformational Challenge Reactor (4)

- Transportation (37)

Media Contacts

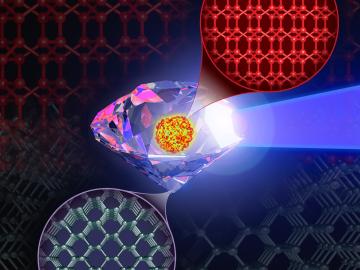

The world’s fastest supercomputer helped researchers simulate synthesizing a material harder and tougher than a diamond — or any other substance on Earth. The study used Frontier to predict the likeliest strategy to synthesize such a material, thought to exist so far only within the interiors of giant exoplanets, or planets beyond our solar system.

Power companies and electric grid developers turn to simulation tools as they attempt to understand how modern equipment will be affected by rapidly unfolding events in a complex grid.

Researchers at the Department of Energy’s Oak Ridge National Laboratory and partner institutions have launched a project to develop an innovative suite of tools that will employ machine learning algorithms for more effective cybersecurity analysis of the U.S. power grid.

In the wet, muddy places where America’s rivers and lands meet the sea, scientists from the Department of Energy’s Oak Ridge National Laboratory are unearthing clues to better understand how these vital landscapes are evolving under climate change.

Phani Ratna Vanamali Marthi, an R&D associate in the Power Systems Resilience group at ORNL, has been elevated to the grade of senior member of the Institute of Electrical and Electronics Engineers, the world’s largest technical professional

John Lagergren, a staff scientist in Oak Ridge National Laboratory’s Plant Systems Biology group, is using his expertise in applied math and machine learning to develop neural networks to quickly analyze the vast amounts of data on plant traits amassed at ORNL’s Advanced Plant Phenotyping Laboratory.

Scientists at Oak Ridge National Laboratory and six other Department of Energy national laboratories have developed a United States-based perspective for achieving net-zero carbon emissions.

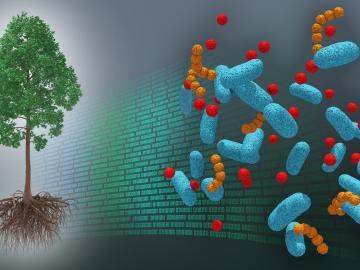

A first-ever dataset bridging molecular information about the poplar tree microbiome to ecosystem-level processes has been released by a team of DOE scientists led by ORNL. The project aims to inform research regarding how natural systems function, their vulnerability to a changing climate and ultimately how plants might be engineered for better performance as sources of bioenergy and natural carbon storage.

SkyNano, an Innovation Crossroads alumnus, held a ribbon-cutting for their new facility. SkyNano exemplifies using DOE resources to build a successful clean energy company, making valuable carbon nanotubes from waste CO2.

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.