Filter News

Area of Research

- Advanced Manufacturing (2)

- Biology and Environment (8)

- Clean Energy (15)

- Electricity and Smart Grid (1)

- Functional Materials for Energy (2)

- Fusion and Fission (22)

- Fusion Energy (5)

- Isotopes (6)

- Materials (48)

- Materials Characterization (2)

- Materials for Computing (2)

- Materials Under Extremes (1)

- National Security (5)

- Neutron Science (7)

- Nuclear Science and Technology (19)

- Supercomputing (11)

News Type

News Topics

- (-) Materials (74)

- (-) Nuclear Energy (68)

- 3-D Printing/Advanced Manufacturing (56)

- Advanced Reactors (13)

- Artificial Intelligence (54)

- Big Data (28)

- Bioenergy (57)

- Biology (65)

- Biomedical (32)

- Biotechnology (11)

- Buildings (24)

- Chemical Sciences (35)

- Clean Water (14)

- Climate Change (57)

- Composites (10)

- Computer Science (99)

- Coronavirus (21)

- Critical Materials (3)

- Cybersecurity (20)

- Decarbonization (49)

- Education (1)

- Emergency (2)

- Energy Storage (44)

- Environment (118)

- Exascale Computing (27)

- Fossil Energy (4)

- Frontier (27)

- Fusion (39)

- Grid (26)

- High-Performance Computing (55)

- Hydropower (5)

- Irradiation (1)

- Isotopes (35)

- ITER (3)

- Machine Learning (24)

- Materials Science (65)

- Mathematics (6)

- Mercury (7)

- Microelectronics (2)

- Microscopy (28)

- Molten Salt (2)

- Nanotechnology (28)

- National Security (43)

- Net Zero (9)

- Neutron Science (59)

- Partnerships (21)

- Physics (34)

- Polymers (13)

- Quantum Computing (22)

- Quantum Science (34)

- Renewable Energy (1)

- Security (14)

- Simulation (35)

- Software (1)

- Space Exploration (13)

- Statistics (1)

- Summit (32)

- Sustainable Energy (52)

- Transformational Challenge Reactor (4)

- Transportation (37)

Media Contacts

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

Steven Arndt, distinguished R&D staff member in the Nuclear Energy and Fuel Cycle Division at ORNL, began a one-year term on June 16 as the 68th President of the American Nuclear Society.

Adrian Sabau of the Department of Energy’s Oak Ridge National Laboratory has been named an ASM International Fellow.

Friederike (Rike) Bostelmann, who began her career in Germany, chose to come to ORNL to become part of the Lab’s efforts to shape the future of nuclear energy.

To achieve practical energy from fusion, extreme heat from the fusion system “blanket” component must be extracted safely and efficiently. ORNL fusion experts are exploring how tiny 3D-printed obstacles placed inside the narrow pipes of a custom-made cooling system could be a solution for removing heat from the blanket.

A study led by researchers at ORNL could help make materials design as customizable as point-and-click.

A study by researchers at the ORNL takes a fresh look at what could become the first step toward a new generation of solar batteries.

ORNL, TVA and TNECD were recognized by the Federal Laboratory Consortium for their impactful partnership that resulted in a record $2.3 billion investment by Ultium Cells, a General Motors and LG Energy Solution joint venture, to build a battery cell manufacturing plant in Spring Hill, Tennessee.

Materials scientist and chemist Nancy Dudney has been elected to the National Academy of Engineering for her groundbreaking research and development of high-performance solid-state rechargeable batteries.

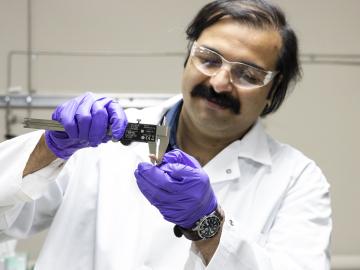

Muralidharan was recognized for “a highly prolific spirit of innovation in creating or facilitating outstanding inventions that have made a tangible impact on the quality of life, economic development and welfare of society.”