Filter News

Area of Research

- Advanced Manufacturing (2)

- Biology and Environment (14)

- Clean Energy (17)

- Computational Biology (1)

- Computer Science (2)

- Fuel Cycle Science and Technology (2)

- Fusion and Fission (27)

- Fusion Energy (5)

- Isotope Development and Production (1)

- Isotopes (4)

- Materials (22)

- Materials for Computing (1)

- National Security (46)

- Neutron Science (10)

- Nuclear Science and Technology (23)

- Supercomputing (44)

News Type

News Topics

- (-) Artificial Intelligence (75)

- (-) Machine Learning (35)

- (-) National Security (53)

- (-) Nuclear Energy (80)

- 3-D Printing/Advanced Manufacturing (81)

- Advanced Reactors (18)

- Big Data (30)

- Bioenergy (74)

- Biology (80)

- Biomedical (45)

- Biotechnology (18)

- Buildings (31)

- Chemical Sciences (51)

- Clean Water (15)

- Climate Change (70)

- Composites (15)

- Computer Science (139)

- Coronavirus (34)

- Critical Materials (13)

- Cybersecurity (31)

- Decarbonization (64)

- Education (4)

- Element Discovery (1)

- Emergency (2)

- Energy Storage (69)

- Environment (137)

- Exascale Computing (34)

- Fossil Energy (5)

- Frontier (38)

- Fusion (43)

- Grid (38)

- High-Performance Computing (69)

- Hydropower (5)

- Isotopes (45)

- ITER (4)

- Materials (100)

- Materials Science (94)

- Mathematics (6)

- Mercury (9)

- Microelectronics (3)

- Microscopy (36)

- Molten Salt (3)

- Nanotechnology (42)

- Net Zero (11)

- Neutron Science (96)

- Partnerships (43)

- Physics (52)

- Polymers (20)

- Quantum Computing (29)

- Quantum Science (56)

- Renewable Energy (2)

- Security (22)

- Simulation (38)

- Software (1)

- Space Exploration (15)

- Statistics (2)

- Summit (50)

- Sustainable Energy (74)

- Transformational Challenge Reactor (7)

- Transportation (52)

Media Contacts

Six ORNL scientists have been elected as fellows to the American Association for the Advancement of Science, or AAAS.

David Kropaczek, director of the Consortium for Advanced Simulation of Light Water Reactors, or CASL, at the Department of Energy’s Oak Ridge National Laboratory, has been named a fellow of the American Nuclear Society.

Chuck Kessel was still in high school when he saw a scientist hold up a tiny vial of water and say, “This could fuel a house for a whole year.”

ORNL and three partnering institutions have received $4.2 million over three years to apply artificial intelligence to the advancement of complex systems in which human decision making could be enhanced via technology.

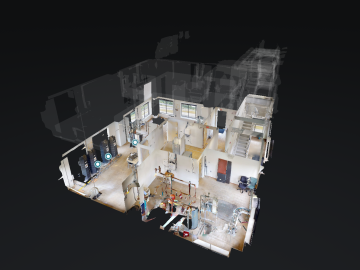

ORNL has added 10 virtual tours to its campus map, each with multiple views to show floor plans, rotating dollhouse views and 360-degree navigation. As a user travels through a map, pop-out informational windows deliver facts, videos, graphics and links to other related content.

The Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new advanced technologies, could be operational by 2024.

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

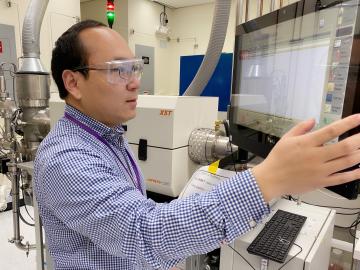

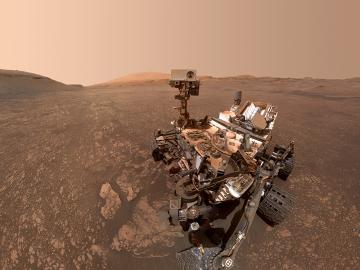

Radioactive isotopes power some of NASA’s best-known spacecraft. But predicting how radiation emitted from these isotopes might affect nearby materials is tricky

The Department of Energy announced awards for 10 projects with private industry that will allow for collaboration with DOE national laboratories in accelerating fusion energy development.

The inside of future nuclear fusion energy reactors will be among the harshest environments ever produced on Earth. What’s strong enough to protect the inside of a fusion reactor from plasma-produced heat fluxes akin to space shuttles reentering Earth’s atmosphere?