Filter News

Area of Research

News Type

News Topics

- (-) Composites (17)

- (-) Emergency (2)

- (-) Exascale Computing (27)

- (-) Isotopes (32)

- (-) Materials (78)

- (-) Space Exploration (22)

- (-) Transportation (62)

- 3-D Printing/Advanced Manufacturing (72)

- Advanced Reactors (21)

- Artificial Intelligence (61)

- Big Data (43)

- Bioenergy (67)

- Biology (78)

- Biomedical (40)

- Biotechnology (14)

- Buildings (38)

- Chemical Sciences (35)

- Clean Water (27)

- Climate Change (72)

- Computer Science (126)

- Coronavirus (28)

- Critical Materials (15)

- Cybersecurity (17)

- Decarbonization (55)

- Education (1)

- Energy Storage (60)

- Environment (147)

- Fossil Energy (5)

- Frontier (25)

- Fusion (40)

- Grid (46)

- High-Performance Computing (55)

- Hydropower (11)

- Irradiation (2)

- ITER (5)

- Machine Learning (33)

- Materials Science (79)

- Mathematics (9)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Molten Salt (6)

- Nanotechnology (28)

- National Security (42)

- Net Zero (10)

- Neutron Science (74)

- Nuclear Energy (74)

- Partnerships (19)

- Physics (33)

- Polymers (17)

- Quantum Computing (25)

- Quantum Science (40)

- Renewable Energy (1)

- Security (12)

- Simulation (39)

- Software (1)

- Statistics (2)

- Summit (36)

- Sustainable Energy (92)

- Transformational Challenge Reactor (3)

Media Contacts

Two ORNL teams recently completed Cohort 18 of Energy I-Corps, an immersive two-month training program where the scientists define their technology’s value propositions, conduct stakeholder discovery interviews and develop viable market pathways.

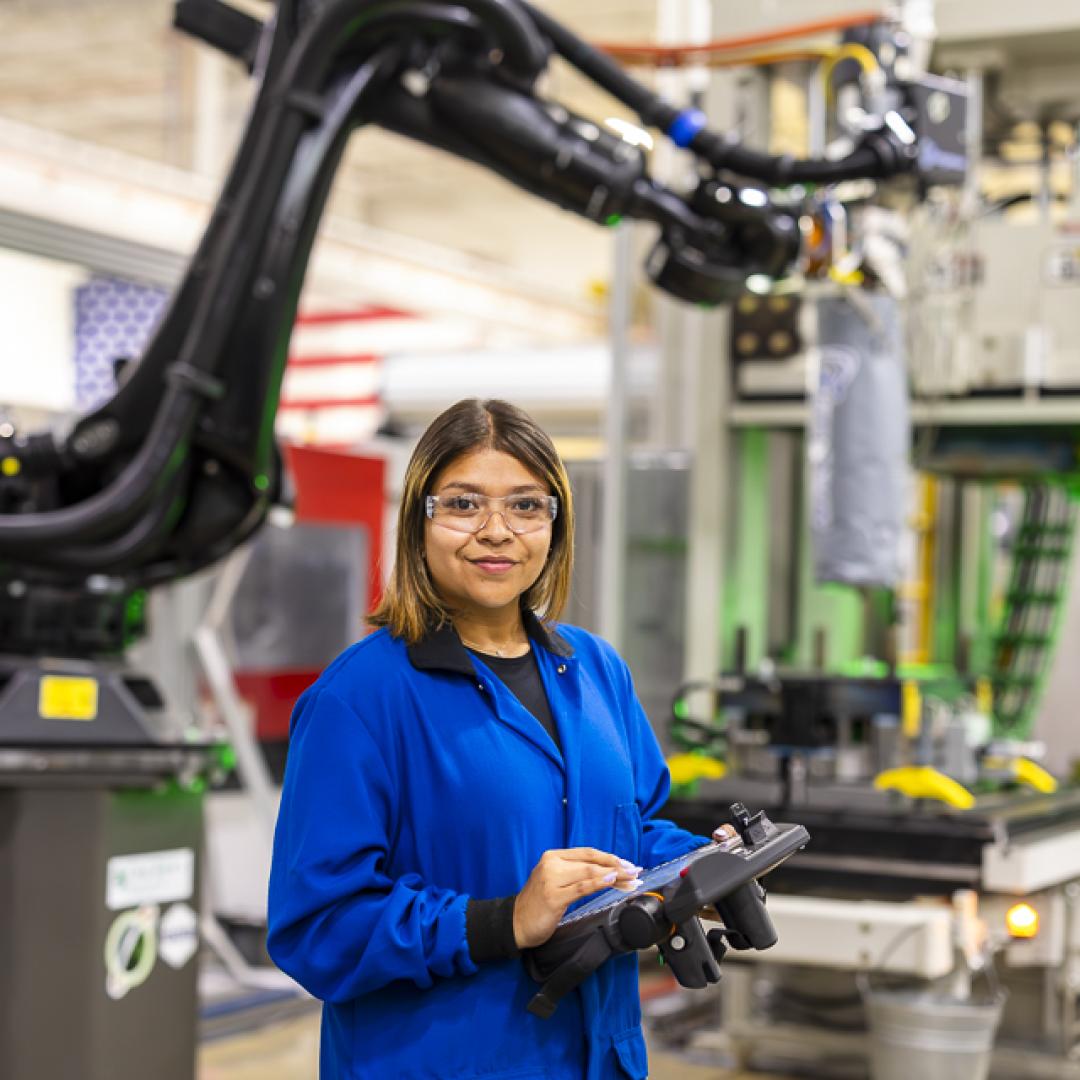

Brittany Rodriguez never imagined she would pursue a science career at a Department of Energy national laboratory. However, after some encouraging words from her mother, input from key mentors at the University of Texas Rio Grande Valley, or UTRGV, and a lot of hard work, Rodriguez landed at DOE’s Manufacturing Demonstration Facility, or MDF, at Oak Ridge National Laboratory.

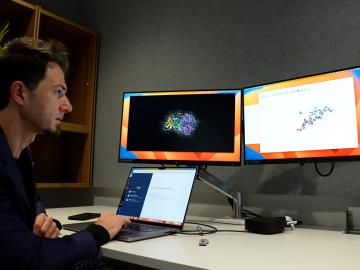

Researchers conduct largest, most accurate molecular dynamics simulations to date of two million correlated electrons using Frontier, the world’s fastest supercomputer. The simulation, which exceed an exaflop using full double precision, is 1,000 times greater in size and speed than any quantum chemistry simulation of it's kind.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

Sara Martinez ensures the safety and longevity of aging structures at Oak Ridge National Laboratory, employing her engineering expertise to protect against natural disasters and extend the lifespan of critical facilities.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.

Early career scientist Frankie White's was part of two major isotope projects at the same time he was preparing to be a father. As co-lead on a team that achieved the first synthesis and characterization of a radium compound using single crystal X-ray diffraction and part of a team that characterized the properties of promethium, White reflects on the life-changing timeline at work, and at home.

Building innovations from ORNL will be on display in Washington, D.C. on the National Mall June 7 to June 9, 2024, during the U.S. Department of Housing and Urban Development’s Innovation Housing Showcase. For the first time, ORNL’s real-time building evaluator was demonstrated outside of a laboratory setting and deployed for building construction.

John Lagergren, a staff scientist in Oak Ridge National Laboratory’s Plant Systems Biology group, is using his expertise in applied math and machine learning to develop neural networks to quickly analyze the vast amounts of data on plant traits amassed at ORNL’s Advanced Plant Phenotyping Laboratory.

ORNL researchers used electron-beam additive manufacturing to 3D-print the first complex, defect-free tungsten parts with complex geometries.