Filter News

Area of Research

News Type

News Topics

- (-) Composites (15)

- (-) Isotopes (30)

- 3-D Printing/Advanced Manufacturing (66)

- Advanced Reactors (21)

- Artificial Intelligence (58)

- Big Data (36)

- Bioenergy (64)

- Biology (74)

- Biomedical (39)

- Biotechnology (13)

- Buildings (35)

- Chemical Sciences (29)

- Clean Water (27)

- Climate Change (68)

- Computer Science (119)

- Coronavirus (28)

- Critical Materials (13)

- Cybersecurity (17)

- Decarbonization (51)

- Education (1)

- Emergency (2)

- Energy Storage (59)

- Environment (143)

- Exascale Computing (25)

- Fossil Energy (4)

- Frontier (24)

- Fusion (37)

- Grid (43)

- High-Performance Computing (53)

- Hydropower (11)

- Irradiation (2)

- ITER (5)

- Machine Learning (31)

- Materials (75)

- Materials Science (75)

- Mathematics (6)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Molten Salt (6)

- Nanotechnology (28)

- National Security (36)

- Net Zero (9)

- Neutron Science (73)

- Nuclear Energy (70)

- Partnerships (15)

- Physics (30)

- Polymers (17)

- Quantum Computing (22)

- Quantum Science (38)

- Renewable Energy (1)

- Security (11)

- Simulation (35)

- Software (1)

- Space Exploration (22)

- Statistics (1)

- Summit (36)

- Sustainable Energy (87)

- Transformational Challenge Reactor (3)

- Transportation (62)

Media Contacts

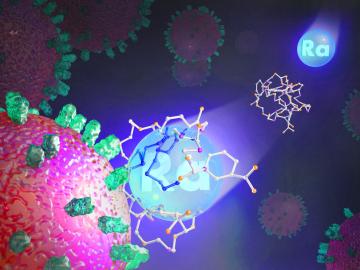

Researchers at ORNL explored radium’s chemistry to advance cancer treatments using ionizing radiation.

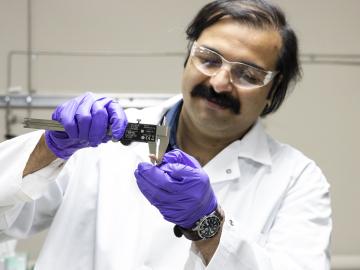

Chemical and environmental engineer Samarthya Bhagia is focused on achieving carbon neutrality and a circular economy by designing new plant-based materials for a range of applications from energy storage devices and sensors to environmentally friendly bioplastics.

Two decades in the making, a new flagship facility for nuclear physics opened on May 2, and scientists from the Department of Energy’s Oak Ridge National Laboratory have a hand in 10 of its first 34 experiments.

A 25-year career with the U.S. Navy, commanding combat missions overseas, brought Tom Kollie back to where he came from — ready to serve his country in a new way.

As a medical isotope, thorium-228 has a lot of potential — and Oak Ridge National Laboratory produces a lot.

A research team at Oak Ridge National Laboratory have 3D printed a thermal protection shield, or TPS, for a capsule that will launch with the Cygnus cargo spacecraft as part of the supply mission to the International Space Station.

An Oak Ridge National Laboratory researcher has invented a version of an isotope-separating device that can withstand extreme environments, including radiation and chemical solvents.

In the mid-1980s, Balendra Sutharshan moved to Canada from the island nation of Sri Lanka. That move set Sutharshan on a path that had him heading continent-spanning collaborations and holding leadership posts at multiple Department of Energy

For years Brenda Smith found fulfillment working with nuclear batteries, a topic she’s been researching as a chemist at Oak Ridge National Laboratory.

Oak Ridge National Laboratory researchers, in collaboration with Cincinnati Inc., demonstrated the potential for using multimaterials and recycled composites in large-scale applications by 3D printing a mold that replicated a single facet of a