Filter News

Area of Research

News Type

News Topics

- (-) Biology (74)

- (-) Transformational Challenge Reactor (3)

- 3-D Printing/Advanced Manufacturing (66)

- Advanced Reactors (21)

- Artificial Intelligence (58)

- Big Data (36)

- Bioenergy (64)

- Biomedical (39)

- Biotechnology (13)

- Buildings (35)

- Chemical Sciences (29)

- Clean Water (27)

- Climate Change (68)

- Composites (15)

- Computer Science (119)

- Coronavirus (28)

- Critical Materials (13)

- Cybersecurity (17)

- Decarbonization (51)

- Education (1)

- Emergency (2)

- Energy Storage (59)

- Environment (143)

- Exascale Computing (25)

- Fossil Energy (4)

- Frontier (24)

- Fusion (37)

- Grid (43)

- High-Performance Computing (53)

- Hydropower (11)

- Irradiation (2)

- Isotopes (30)

- ITER (5)

- Machine Learning (31)

- Materials (75)

- Materials Science (75)

- Mathematics (6)

- Mercury (10)

- Microelectronics (2)

- Microscopy (31)

- Molten Salt (6)

- Nanotechnology (28)

- National Security (36)

- Net Zero (9)

- Neutron Science (73)

- Nuclear Energy (70)

- Partnerships (15)

- Physics (30)

- Polymers (17)

- Quantum Computing (22)

- Quantum Science (38)

- Renewable Energy (1)

- Security (11)

- Simulation (35)

- Software (1)

- Space Exploration (22)

- Statistics (1)

- Summit (36)

- Sustainable Energy (87)

- Transportation (62)

Media Contacts

From soda bottles to car bumpers to piping, electronics, and packaging, plastics have become a ubiquitous part of our lives.

The life of celebrated ORNL biologist Liane Russell was remarkable in many respects — from her childhood flight from Austria ahead of the Nazi invasion to her 60-year career as a trailblazing woman in the field of genetics to her decades of advocacy for environmental causes.

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

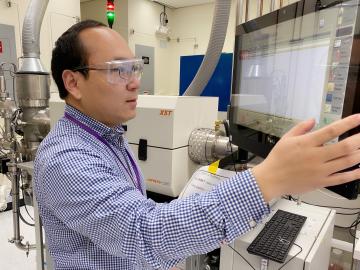

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

Mircea Podar has travelled around the world and to the bottom of the ocean in pursuit of scientific discoveries, but it is the uncharted territory he encounters when working with new microbes that inspires his research at ORNL.

Working backwards has moved Josh Michener’s research far forward as he uses evolution and genetics to engineer microbes for better conversion of plants into biofuels and biochemicals. In his work for the BioEnergy Science Center at ORNL, for instance, “we’ve gotten good at engineering microbes th...