Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (41)

- (-) Advanced Reactors (8)

- (-) Clean Water (14)

- (-) Composites (8)

- (-) Frontier (24)

- (-) ITER (2)

- (-) Molten Salt (1)

- (-) Physics (29)

- (-) Quantum Science (30)

- Artificial Intelligence (48)

- Big Data (26)

- Bioenergy (51)

- Biology (60)

- Biomedical (29)

- Biotechnology (11)

- Buildings (19)

- Chemical Sciences (25)

- Climate Change (50)

- Computer Science (86)

- Coronavirus (17)

- Critical Materials (3)

- Cybersecurity (14)

- Decarbonization (46)

- Education (1)

- Emergency (2)

- Energy Storage (29)

- Environment (104)

- Exascale Computing (26)

- Fossil Energy (4)

- Fusion (31)

- Grid (25)

- High-Performance Computing (44)

- Hydropower (5)

- Isotopes (27)

- Machine Learning (22)

- Materials (43)

- Materials Science (45)

- Mathematics (7)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Nanotechnology (16)

- National Security (39)

- Net Zero (8)

- Neutron Science (47)

- Nuclear Energy (55)

- Partnerships (18)

- Polymers (8)

- Quantum Computing (21)

- Renewable Energy (1)

- Security (11)

- Simulation (32)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (30)

- Sustainable Energy (47)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

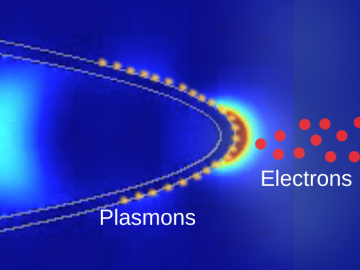

Scientists at ORNL and the University of Nebraska have developed an easier way to generate electrons for nanoscale imaging and sensing, providing a useful new tool for material science, bioimaging and fundamental quantum research.

The Department of Energy has selected Oak Ridge National Laboratory to lead a collaboration charged with developing quantum technologies that will usher in a new era of innovation.

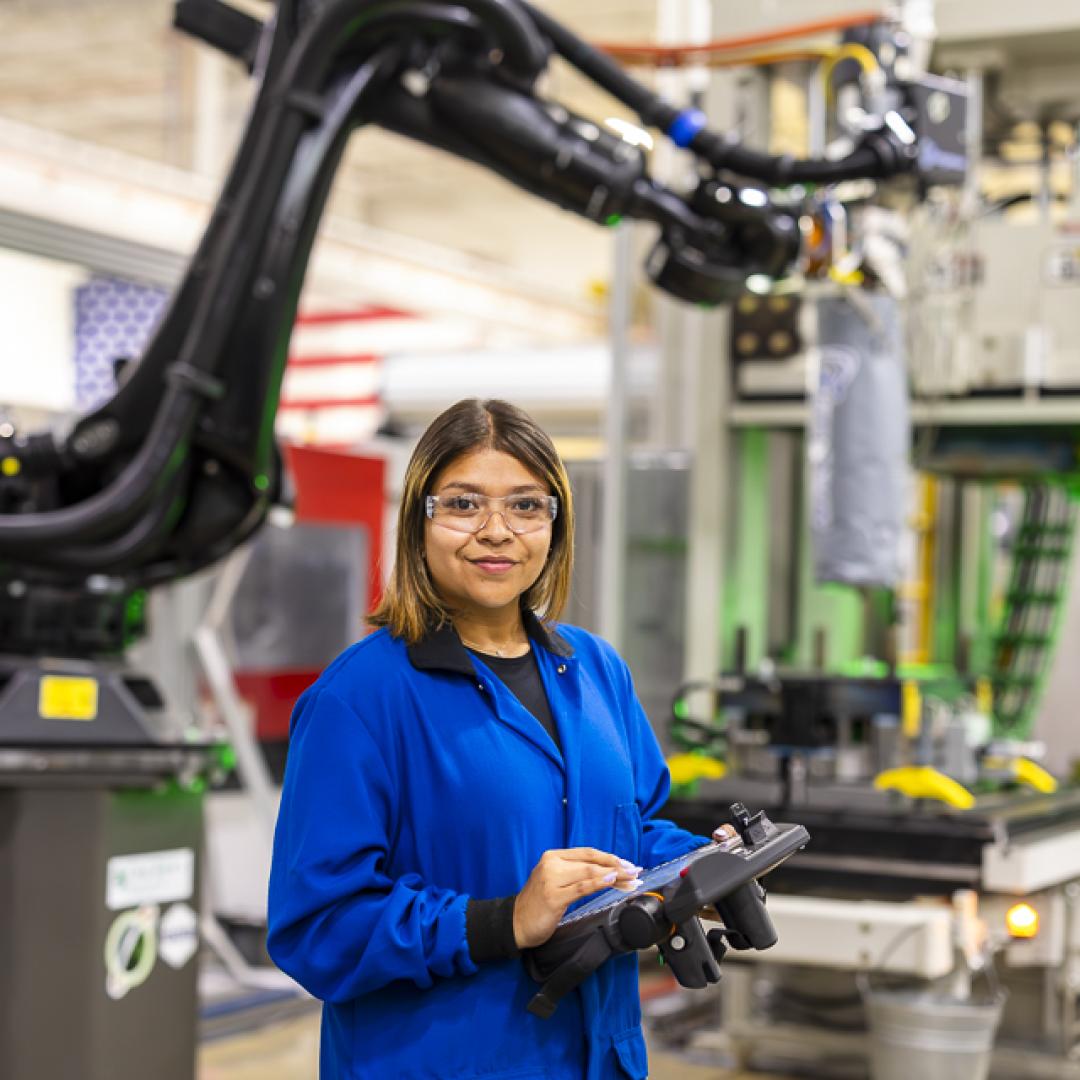

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

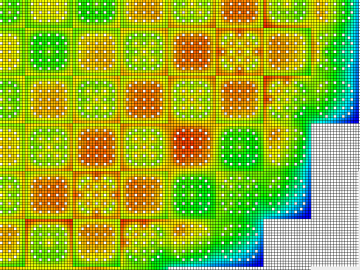

As CASL ends and transitions to VERA Users Group, ORNL looks at the history of the program and its impact on the nuclear industry.

In the search to create materials that can withstand extreme radiation, Yanwen Zhang, a researcher at the Department of Energy’s Oak Ridge National Laboratory, says that materials scientists must think outside the box.

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

In the early 2000s, high-performance computing experts repurposed GPUs — common video game console components used to speed up image rendering and other time-consuming tasks

In the Physics Division of the Department of Energy’s Oak Ridge National Laboratory, James (“Mitch”) Allmond conducts experiments and uses theoretical models to advance our understanding of the structure of atomic nuclei, which are made of various combinations of protons and neutrons (nucleons).

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.