Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (39)

- (-) Fusion (31)

- (-) Materials Science (45)

- (-) Mercury (7)

- (-) Security (11)

- (-) Simulation (31)

- Advanced Reactors (8)

- Artificial Intelligence (46)

- Big Data (24)

- Bioenergy (51)

- Biology (59)

- Biomedical (28)

- Biotechnology (11)

- Buildings (19)

- Chemical Sciences (24)

- Clean Water (14)

- Climate Change (50)

- Composites (6)

- Computer Science (83)

- Coronavirus (17)

- Critical Materials (2)

- Cybersecurity (14)

- Decarbonization (46)

- Education (1)

- Emergency (2)

- Energy Storage (29)

- Environment (104)

- Exascale Computing (25)

- Fossil Energy (4)

- Frontier (24)

- Grid (23)

- High-Performance Computing (44)

- Hydropower (5)

- Isotopes (27)

- ITER (2)

- Machine Learning (22)

- Materials (43)

- Mathematics (7)

- Microelectronics (2)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (37)

- Net Zero (8)

- Neutron Science (47)

- Nuclear Energy (55)

- Partnerships (16)

- Physics (28)

- Polymers (8)

- Quantum Computing (20)

- Quantum Science (30)

- Renewable Energy (1)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (30)

- Sustainable Energy (44)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

Oak Ridge National Laboratory has named Troy A. Carter director of the Fusion Energy Division in ORNL’s Fusion and Fission Energy and Science Directorate, or FFESD.

In the wet, muddy places where America’s rivers and lands meet the sea, scientists from the Department of Energy’s Oak Ridge National Laboratory are unearthing clues to better understand how these vital landscapes are evolving under climate change.

Participants in the SM2ART Research Experience for Undergraduates program got the chance to see what life is like in a research setting. REU participant Brianna Greer studied banana fibers as a reinforcing material in making lightweight parts for cars and bicycles.

Advanced materials research to enable energy-efficient, cost-competitive and environmentally friendly technologies for the United States and Japan is the goal of a memorandum of understanding, or MOU, between the Department of Energy’s Oak Ridge National Laboratory and Japan’s National Institute of Materials Science.

Researchers at ORNL have developed the first additive manufacturing slicing computer application to simultaneously speed and simplify digital conversion of accurate, large-format three-dimensional parts in a factory production setting.

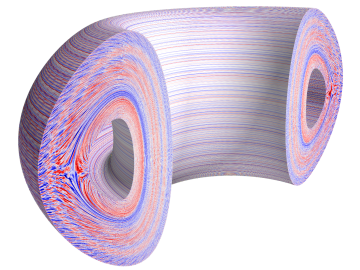

A new study conducted on the Frontier supercomputer gave researchers new clues to improving fusion confinement. This research, in collaboration with General Atomics and UC San Diego, uncovered that the interaction between ions and electrons near the tokamak's edge can unexpectedly increase turbulence, challenging previous assumptions about how to optimize plasma confinement for efficient nuclear fusion.

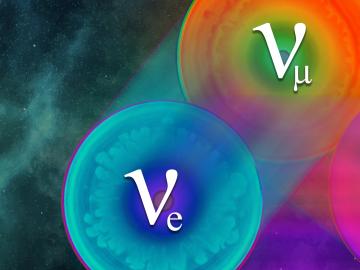

Researchers used quantum simulations to obtain new insights into the nature of neutrinos — the mysterious subatomic particles that abound throughout the universe — and their role in the deaths of massive stars.

In May, the Department of Energy’s Oak Ridge and Brookhaven national laboratories co-hosted the 15th annual International Particle Accelerator Conference, or IPAC, at the Music City Center in Nashville, Tennessee.

Researchers at ORNL and the University of Maine have designed and 3D-printed a single-piece, recyclable natural-material floor panel tested to be strong enough to replace construction materials like steel.

Building innovations from ORNL will be on display in Washington, D.C. on the National Mall June 7 to June 9, 2024, during the U.S. Department of Housing and Urban Development’s Innovation Housing Showcase. For the first time, ORNL’s real-time building evaluator was demonstrated outside of a laboratory setting and deployed for building construction.