Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (36)

- (-) Biology (57)

- (-) Neutron Science (47)

- (-) Transportation (27)

- Advanced Reactors (8)

- Artificial Intelligence (45)

- Big Data (21)

- Bioenergy (49)

- Biomedical (28)

- Biotechnology (10)

- Buildings (17)

- Chemical Sciences (21)

- Clean Water (14)

- Climate Change (47)

- Composites (6)

- Computer Science (81)

- Coronavirus (17)

- Critical Materials (1)

- Cybersecurity (14)

- Decarbonization (43)

- Education (1)

- Emergency (2)

- Energy Storage (28)

- Environment (100)

- Exascale Computing (24)

- Fossil Energy (4)

- Frontier (23)

- Fusion (29)

- Grid (23)

- High-Performance Computing (42)

- Hydropower (5)

- Isotopes (26)

- ITER (2)

- Machine Learning (21)

- Materials (40)

- Materials Science (43)

- Mathematics (5)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (34)

- Net Zero (8)

- Nuclear Energy (52)

- Partnerships (15)

- Physics (28)

- Polymers (8)

- Quantum Computing (20)

- Quantum Science (30)

- Renewable Energy (1)

- Security (10)

- Simulation (30)

- Software (1)

- Space Exploration (12)

- Summit (30)

- Sustainable Energy (43)

- Transformational Challenge Reactor (3)

Media Contacts

Yarom Polsky, director of the Manufacturing Science Division, or MSD, at the Department of Energy’s Oak Ridge National Laboratory, has been elected a Fellow of the American Society of Mechanical Engineers, or ASME.

Early experiments at the Department of Energy’s Oak Ridge National Laboratory have revealed significant benefits to a dry battery manufacturing process. This eliminates the use of solvents and is more affordable, while showing promise for delivering a battery that is durable, less weighed down by inactive elements, and able to maintain a high capacity after use.

Researchers at the Department of Energy’s Oak Ridge National Laboratory were the first to use neutron reflectometry to peer inside a working solid-state battery and monitor its electrochemistry.

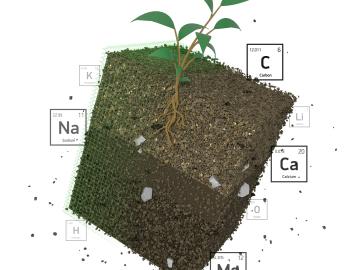

Oak Ridge National Laboratory researchers recently demonstrated use of a laser-based analytical method to accelerate understanding of critical plant and soil properties that affect bioenergy plant growth and soil carbon storage.

Ken Herwig's scientific drive crystallized in his youth when he solved a tough algebra word problem in his head while tossing newspapers from his bicycle. He said the joy he felt in that moment as a teenager fueled his determination to conquer mathematical mysteries. And he did.

To support the development of a revolutionary new open fan engine architecture for the future of flight, GE Aerospace has run simulations using the world’s fastest supercomputer capable of crunching data in excess of exascale speed, or more than a quintillion calculations per second.

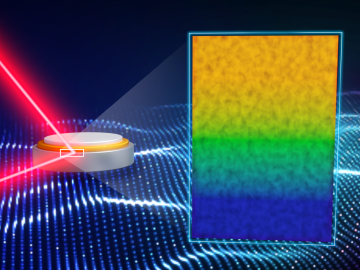

When opportunity meets talent, great things happen. The laser comb developed at ORNL serves as such an example.

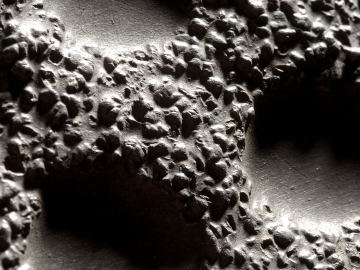

For more than 100 years, Magotteaux has provided grinding materials and castings for the mining, cement and aggregates industries. The company, based in Belgium, began its international expansion in 1968. Its second international plant has been a critical part of the Pulaski, Tennessee, economy since 1972.

Nature-based solutions are an effective tool to combat climate change triggered by rising carbon emissions, whether it’s by clearing the skies with bio-based aviation fuels or boosting natural carbon sinks.

On the grounds of the University of Maine’s Advanced Structures and Composites Center sits the nation’s first additively manufactured home made entirely from biobased materials - BioHome3D.