Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (37)

- (-) Transportation (27)

- Advanced Reactors (8)

- Artificial Intelligence (46)

- Big Data (22)

- Bioenergy (50)

- Biology (58)

- Biomedical (28)

- Biotechnology (11)

- Buildings (18)

- Chemical Sciences (22)

- Clean Water (14)

- Climate Change (48)

- Composites (6)

- Computer Science (82)

- Coronavirus (17)

- Critical Materials (2)

- Cybersecurity (14)

- Decarbonization (45)

- Education (1)

- Emergency (2)

- Energy Storage (28)

- Environment (101)

- Exascale Computing (25)

- Fossil Energy (4)

- Frontier (24)

- Fusion (30)

- Grid (23)

- High-Performance Computing (43)

- Hydropower (5)

- Isotopes (27)

- ITER (2)

- Machine Learning (22)

- Materials (41)

- Materials Science (44)

- Mathematics (6)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (35)

- Net Zero (8)

- Neutron Science (47)

- Nuclear Energy (54)

- Partnerships (16)

- Physics (28)

- Polymers (8)

- Quantum Computing (20)

- Quantum Science (30)

- Renewable Energy (1)

- Security (11)

- Simulation (30)

- Software (1)

- Space Exploration (12)

- Summit (30)

- Sustainable Energy (43)

- Transformational Challenge Reactor (3)

Media Contacts

Soteria Battery Innovation Group has exclusively licensed and optioned a technology developed by Oak Ridge National Laboratory designed to eliminate thermal runaway in lithium ion batteries due to mechanical damage.

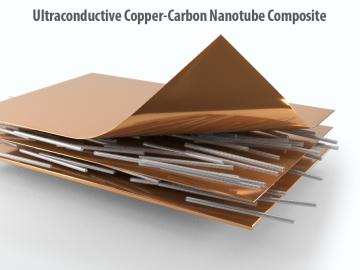

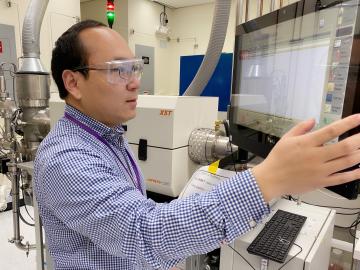

Scientists at Oak Ridge National Laboratory used new techniques to create a composite that increases the electrical current capacity of copper wires, providing a new material that can be scaled for use in ultra-efficient, power-dense electric vehicle traction motors.

About 60 years ago, scientists discovered that a certain rare earth metal-hydrogen mixture, yttrium, could be the ideal moderator to go inside small, gas-cooled nuclear reactors.

It’s a new type of nuclear reactor core. And the materials that will make it up are novel — products of Oak Ridge National Laboratory’s advanced materials and manufacturing technologies.

Scientists at the Department of Energy Manufacturing Demonstration Facility at ORNL have their eyes on the prize: the Transformational Challenge Reactor, or TCR, a microreactor built using 3D printing and other new approaches that will be up and running by 2023.

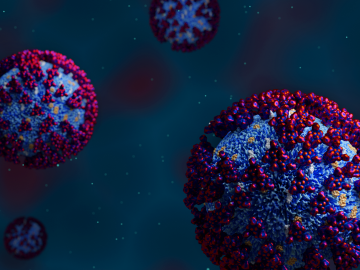

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) in late February demonstrated a 20-kilowatt bi-directional wireless charging system installed on a UPS medium-duty, plug-in hybrid electric delivery truck.

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.

Hydropower developers must consider many factors when it comes time to license a new project or renew an existing one: How can environmental impacts be mitigated, including to fish populations?

Each year, approximately 6 billion gallons of fuel are wasted as vehicles wait at stop lights or sit in dense traffic with engines idling, according to US Department of Energy estimates.