Filter News

Area of Research

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (42)

- (-) Exascale Computing (27)

- (-) Nuclear Energy (55)

- Advanced Reactors (8)

- Artificial Intelligence (48)

- Big Data (27)

- Bioenergy (51)

- Biology (60)

- Biomedical (29)

- Biotechnology (11)

- Buildings (19)

- Chemical Sciences (25)

- Clean Water (14)

- Climate Change (50)

- Composites (8)

- Computer Science (87)

- Coronavirus (17)

- Critical Materials (4)

- Cybersecurity (14)

- Decarbonization (46)

- Education (1)

- Emergency (2)

- Energy Storage (29)

- Environment (104)

- Fossil Energy (4)

- Frontier (25)

- Fusion (31)

- Grid (25)

- High-Performance Computing (45)

- Hydropower (5)

- Isotopes (27)

- ITER (2)

- Machine Learning (22)

- Materials (43)

- Materials Science (46)

- Mathematics (7)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (39)

- Net Zero (8)

- Neutron Science (47)

- Partnerships (18)

- Physics (29)

- Polymers (8)

- Quantum Computing (21)

- Quantum Science (30)

- Renewable Energy (1)

- Security (11)

- Simulation (32)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (31)

- Sustainable Energy (47)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

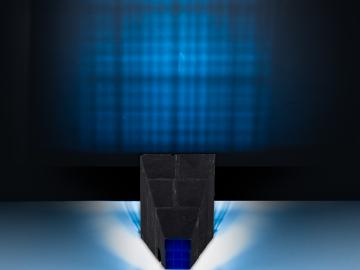

Integral to the functionality of ORNL's Frontier supercomputer is its ability to store the vast amounts of data it produces onto its file system, Orion. But even more important to the computational scientists running simulations on Frontier is their capability to quickly write and read to Orion along with effectively analyzing all that data. And that’s where ADIOS comes in.

Rishi Pillai and his research team from ORNL will receive a Best Paper award from the American Society of Mechanical Engineers International Gas Turbine Institute in June at the Turbo Expo 2024 in London.

ORNL’s Erin Webb is co-leading a new Circular Bioeconomy Systems Convergent Research Initiative focused on advancing production and use of renewable carbon from Tennessee to meet societal needs.

Scientists at ORNL have developed 3-D-printed collimator techniques that can be used to custom design collimators that better filter out noise during different types of neutron scattering experiments

ORNL scientists have determined how to avoid costly and potentially irreparable damage to large metallic parts fabricated through additive manufacturing, also known as 3D printing, that is caused by residual stress in the material.

Three staff members in ORNL’s Fusion and Fission Energy and Science Directorate have moved into newly established roles facilitating communication and program management with sponsors of the directorate’s Nuclear Energy and Fuel Cycle Division.

In summer 2023, ORNL's Prasanna Balaprakash was invited to speak at a roundtable discussion focused on the importance of academic artificial intelligence research and development hosted by the White House Office of Science and Technology Policy and the U.S. National Science Foundation.

Researchers at ORNL became the first to 3D-print large rotating steam turbine blades for generating energy in power plants.

Nuclear engineering students from the United States Military Academy and United States Naval Academy are working with researchers at ORNL to complete design concepts for a nuclear propulsion rocket to go to space in 2027 as part of the Defense Advanced Research Projects Agency DRACO program.

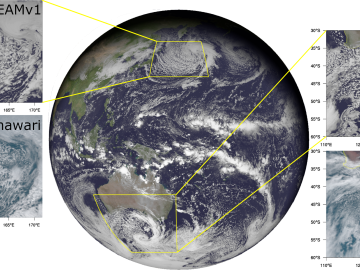

A 19-member team of scientists from across the national laboratory complex won the Association for Computing Machinery’s 2023 Gordon Bell Special Prize for Climate Modeling for developing a model that uses the world’s first exascale supercomputer to simulate decades’ worth of cloud formations.