Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (42)

- (-) Nuclear Energy (56)

- Advanced Reactors (8)

- Artificial Intelligence (48)

- Big Data (27)

- Bioenergy (51)

- Biology (60)

- Biomedical (29)

- Biotechnology (12)

- Buildings (20)

- Chemical Sciences (27)

- Clean Water (14)

- Climate Change (51)

- Composites (8)

- Computer Science (87)

- Coronavirus (17)

- Critical Materials (5)

- Cybersecurity (14)

- Decarbonization (46)

- Education (1)

- Emergency (2)

- Energy Storage (30)

- Environment (105)

- Exascale Computing (27)

- Fossil Energy (4)

- Frontier (25)

- Fusion (31)

- Grid (25)

- High-Performance Computing (45)

- Hydropower (5)

- Isotopes (28)

- ITER (2)

- Machine Learning (22)

- Materials (44)

- Materials Science (47)

- Mathematics (7)

- Mercury (7)

- Microelectronics (3)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (42)

- Net Zero (8)

- Neutron Science (49)

- Partnerships (19)

- Physics (30)

- Polymers (8)

- Quantum Computing (21)

- Quantum Science (31)

- Renewable Energy (1)

- Security (11)

- Simulation (32)

- Software (1)

- Space Exploration (12)

- Statistics (1)

- Summit (31)

- Sustainable Energy (47)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

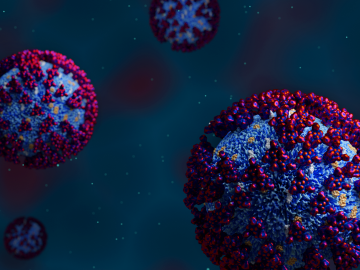

In the fight against the COVID-19 pandemic, it’s a race against the clock not only to find a vaccine but also to supply healthcare workers with life-saving equipment such as face shields, masks and test kits.

In the race to identify solutions to the COVID-19 pandemic, researchers at the Department of Energy’s Oak Ridge National Laboratory are joining the fight by applying expertise in computational science, advanced manufacturing, data science and neutron science.

As a teenager, Kat Royston had a lot of questions. Then an advanced-placement class in physics convinced her all the answers were out there.

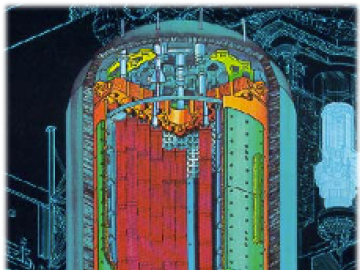

A software package, 10 years in the making, that can predict the behavior of nuclear reactors’ cores with stunning accuracy has been licensed commercially for the first time.

Hydropower developers must consider many factors when it comes time to license a new project or renew an existing one: How can environmental impacts be mitigated, including to fish populations?

The techniques Theodore Biewer and his colleagues are using to measure whether plasma has the right conditions to create fusion have been around awhile.

Peter Wang is focused on robotics and automation at the Department of Energy’s Manufacturing Demonstration Facility at ORNL, working on high-profile projects such as the MedUSA, a large-scale hybrid additive manufacturing machine.

Ask Tyler Gerczak to find a negative in working at the Department of Energy’s Oak Ridge National Laboratory, and his only complaint is the summer weather. It is not as forgiving as the summers in Pulaski, Wisconsin, his hometown.

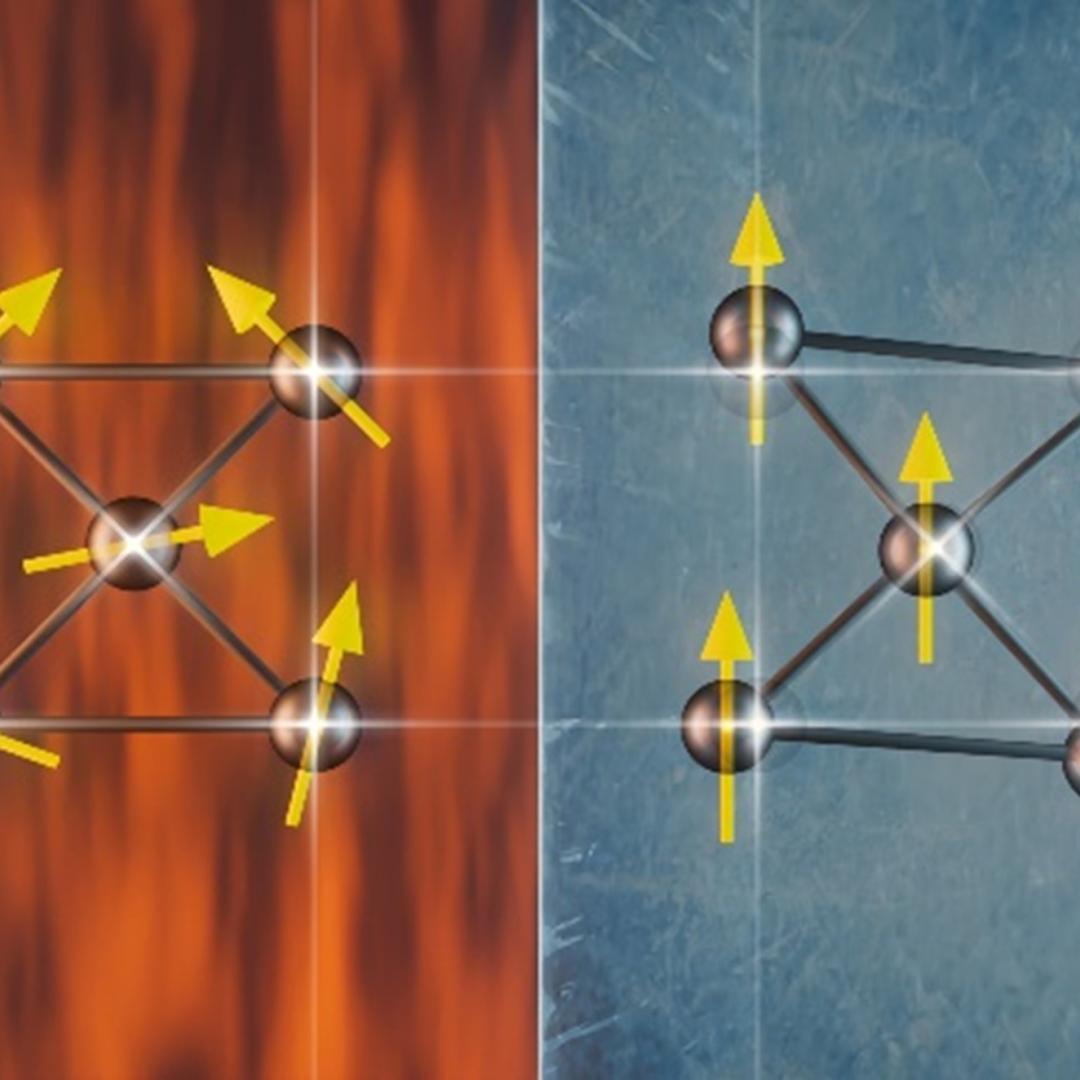

Six new nuclear reactor technologies are set to deploy for commercial use between 2030 and 2040. Called Generation IV nuclear reactors, they will operate with improved performance at dramatically higher temperatures than today’s reactors.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.