Filter News

Area of Research

News Topics

- (-) 3-D Printing/Advanced Manufacturing (37)

- (-) Buildings (18)

- (-) Fossil Energy (4)

- (-) Quantum Computing (20)

- Advanced Reactors (8)

- Artificial Intelligence (46)

- Big Data (22)

- Bioenergy (50)

- Biology (58)

- Biomedical (28)

- Biotechnology (11)

- Chemical Sciences (22)

- Clean Water (14)

- Climate Change (48)

- Composites (6)

- Computer Science (82)

- Coronavirus (17)

- Critical Materials (2)

- Cybersecurity (14)

- Decarbonization (45)

- Education (1)

- Emergency (2)

- Energy Storage (28)

- Environment (101)

- Exascale Computing (25)

- Frontier (24)

- Fusion (30)

- Grid (23)

- High-Performance Computing (43)

- Hydropower (5)

- Isotopes (27)

- ITER (2)

- Machine Learning (22)

- Materials (41)

- Materials Science (44)

- Mathematics (6)

- Mercury (7)

- Microelectronics (2)

- Microscopy (20)

- Molten Salt (1)

- Nanotechnology (16)

- National Security (35)

- Net Zero (8)

- Neutron Science (47)

- Nuclear Energy (54)

- Partnerships (16)

- Physics (28)

- Polymers (8)

- Quantum Science (30)

- Renewable Energy (1)

- Security (11)

- Simulation (30)

- Software (1)

- Space Exploration (12)

- Summit (30)

- Sustainable Energy (43)

- Transformational Challenge Reactor (3)

- Transportation (27)

Media Contacts

Researchers at the Department of Energy’s Oak Ridge National Laboratory have created a new detection system that allows home energy auditors to see air leaking from a building in real time with the help of a camera.

Kashif Nawaz and Mahabir Bhandari, building technologies researchers at the Department of Energy’s Oak Ridge National Laboratory, were recognized for research achievements in support of ASHRAE during the 2023 annual conference.

Quantum computing sits on the cutting edge of scientific discovery. Given its novelty, the next generation of researchers will contribute significantly to the advancement of the field. However, this new crop of scientists must first be cultivated.

Yarom Polsky, director of the Manufacturing Science Division, or MSD, at the Department of Energy’s Oak Ridge National Laboratory, has been elected a Fellow of the American Society of Mechanical Engineers, or ASME.

Early experiments at the Department of Energy’s Oak Ridge National Laboratory have revealed significant benefits to a dry battery manufacturing process. This eliminates the use of solvents and is more affordable, while showing promise for delivering a battery that is durable, less weighed down by inactive elements, and able to maintain a high capacity after use.

In late May, the Quantum Science Center convened its first in-person all-hands meeting since the center was established in 2020. More than 120 QSC members gathered in Nashville, Tennessee to discuss the center’s operations, research and overarching scientific aims.

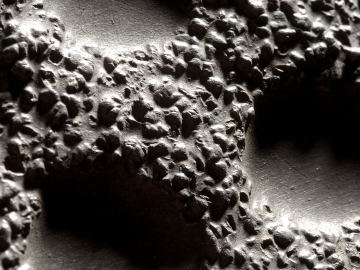

For more than 100 years, Magotteaux has provided grinding materials and castings for the mining, cement and aggregates industries. The company, based in Belgium, began its international expansion in 1968. Its second international plant has been a critical part of the Pulaski, Tennessee, economy since 1972.

For the third year in a row, the Quantum Science Center held its signature workforce development event: a comprehensive summer school for students and early-career scientists designed to facilitate conversations and hands-on activities related to

Researchers used Oak Ridge National Laboratory’s Quantum Computing User Program to perform the first independent comparison test of leading quantum computers.

On the grounds of the University of Maine’s Advanced Structures and Composites Center sits the nation’s first additively manufactured home made entirely from biobased materials - BioHome3D.