Filter News

Area of Research

- (-) Clean Energy (98)

- (-) Materials (28)

- (-) Supercomputing (61)

- Advanced Manufacturing (14)

- Biology and Environment (42)

- Biology and Soft Matter (1)

- Building Technologies (1)

- Computational Biology (2)

- Computational Engineering (2)

- Computer Science (7)

- Electricity and Smart Grid (2)

- Fusion and Fission (7)

- Fusion Energy (7)

- Isotopes (18)

- Materials for Computing (5)

- Mathematics (1)

- National Security (16)

- Neutron Science (13)

- Nuclear Science and Technology (12)

- Nuclear Systems Modeling, Simulation and Validation (1)

- Quantum information Science (7)

- Sensors and Controls (1)

- Transportation Systems (1)

News Type

News Topics

- (-) 3-D Printing/Advanced Manufacturing (51)

- (-) Advanced Reactors (5)

- (-) Artificial Intelligence (24)

- (-) Clean Water (9)

- (-) Decarbonization (21)

- (-) Grid (28)

- (-) Isotopes (8)

- (-) Quantum Science (15)

- (-) Summit (28)

- Big Data (18)

- Bioenergy (15)

- Biology (12)

- Biomedical (16)

- Biotechnology (3)

- Buildings (25)

- Chemical Sciences (12)

- Climate Change (26)

- Composites (12)

- Computer Science (72)

- Coronavirus (17)

- Critical Materials (10)

- Cybersecurity (7)

- Energy Storage (45)

- Environment (51)

- Exascale Computing (13)

- Fossil Energy (1)

- Frontier (14)

- Fusion (5)

- High-Performance Computing (23)

- Hydropower (2)

- Machine Learning (10)

- Materials (48)

- Materials Science (46)

- Mathematics (3)

- Mercury (2)

- Microelectronics (1)

- Microscopy (15)

- Molten Salt (1)

- Nanotechnology (18)

- National Security (4)

- Net Zero (3)

- Neutron Science (20)

- Nuclear Energy (18)

- Partnerships (5)

- Physics (15)

- Polymers (12)

- Quantum Computing (15)

- Security (4)

- Simulation (12)

- Software (1)

- Space Exploration (7)

- Statistics (1)

- Sustainable Energy (44)

- Transformational Challenge Reactor (2)

- Transportation (49)

Media Contacts

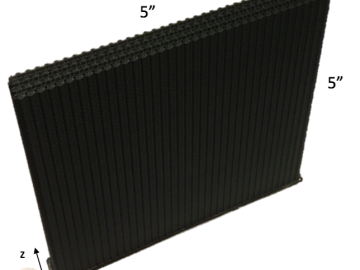

A team including Oak Ridge National Laboratory and University of Tennessee researchers demonstrated a novel 3D printing approach called Z-pinning that can increase the material’s strength and toughness by more than three and a half times compared to conventional additive manufacturing processes.

More than 6,000 veterans died by suicide in 2016, and from 2005 to 2016, the rate of veteran suicides in the United States increased by more than 25 percent.

Artificial intelligence (AI) techniques have the potential to support medical decision-making, from diagnosing diseases to prescribing treatments. But to prioritize patient safety, researchers and practitioners must first ensure such methods are accurate.

Materials scientists, electrical engineers, computer scientists, and other members of the neuromorphic computing community from industry, academia, and government agencies gathered in downtown Knoxville July 23–25 to talk about what comes next in

Isabelle Snyder calls faults as she sees them, whether it’s modeling operations for the nation’s power grid or officiating at the US Open Tennis Championships.

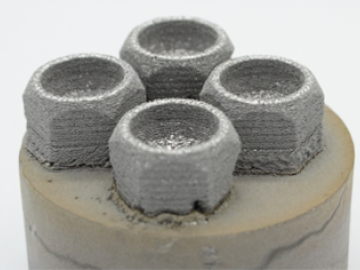

Using additive manufacturing, scientists experimenting with tungsten at Oak Ridge National Laboratory hope to unlock new potential of the high-performance heat-transferring material used to protect components from the plasma inside a fusion reactor. Fusion requires hydrogen isotopes to reach millions of degrees.

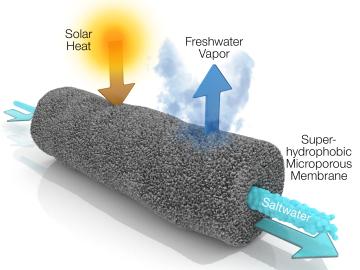

A new method developed at Oak Ridge National Laboratory improves the energy efficiency of a desalination process known as solar-thermal evaporation.

In the shifting landscape of global manufacturing, American ingenuity is once again giving U.S companies an edge with radical productivity improvements as a result of advanced materials and robotic systems developed at the Department of Energy’s Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory.

Environmental conditions, lifestyle choices, chemical exposure, and foodborne and airborne pathogens are among the external factors that can cause disease. In contrast, internal genetic factors can be responsible for the onset and progression of diseases ranging from degenerative neurological disorders to some cancers.

Researchers at the Department of Energy’s Oak Ridge National Laboratory, Pacific Northwest National Laboratory and Washington State University teamed up to investigate the complex dynamics of low-water liquids that challenge nuclear waste processing at federal cleanup sites.